Conditioned biogas, a medium for chemical energy storage, can be injected into the natural gas grid as synthetic natural gas (SNG).

The prerequisite for such injection is that the biogas, which contains methane (CH4) and carbon dioxide (CO2) in equal parts, is preprocessed to reach natural gas quality, with a methane content of at least 95 %. The conversion from biogas to methane can be achieved with biological methanation, in which microorganisms convert carbon dioxide and added hydrogen into methane.

Technically, this process is particularly efficient when performed in bubble column reactors, which do not require energy-intensive components, such as agitators, circulation or gas separation.

In the project “BioStore”, Fraunhofer IKTS is collaborating with DBI – Gastechnologisches Institut gGmbH Freiberg on the development and optimization of efficient reactors adapted to biological methanation. DBI has evaluated various bubble column reactors for this purpose. IKTS examined the bubble distribution in the reactor using process tomography for variable boundary conditions. Pressure, temperature, and gas flow rate were varied, and different spargers (venting elements) were tested.

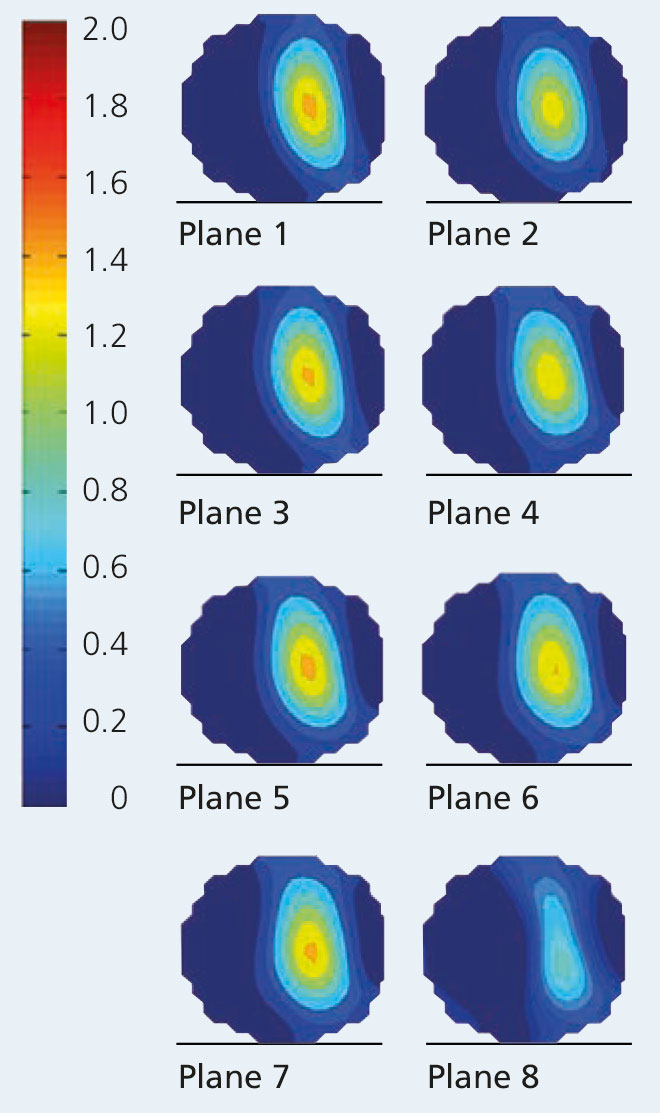

The bubble column test bench with the process tomography unit (ERT) is shown in the top image. ERT provides a view into the reactor and multi-phase processes can be quantified based on different electrical conductivities of the phases to be examined. The volume concentration determined through process tomography at a specific gas flow rate of 0.62 L/(L ∙ h) and 2 bar is shown for the different planes in the bottom figure.

The images show that the gas bubble distribution is inhomogeneous over the cross-sectional area even in the first plane, which is the one nearest to the sparger. Due to the gas flow rate and the associated homogeneous bubble flow, this gradient can be measured over the entire height of the column. These inhomogeneities in the gas distribution have a negative effect on the formation of methane, since areas with low volume concentrations lead to substrate limitation. The aim is, therefore, to achieve a homogeneous gas distribution across the cross-section and column height. Overall, the investigations have shown that design and quality of the sparger have a significant impact on the bubble distribution forming in the reactor, and thus on the phase transition.

Services offered

- Optimization of industrial multi-phase flows with practical importance in various process engineering devices

- Determination of bubble size distribution and bubble rise velocity in bubble column reactors

- Investigation of flow conditions

- Determination of mass transfer coefficients and specific exchange surfaces