Challenges in treating saline waste and process waters

Water is not only a valuable food item but also an essential factor of production and a resource that sometimes limits growth. Attempts to extend production in the chemical, food, pharmaceutical and processing industries often fail because of insufficient water treatment capacities. Therefore, intelligent recycling and innovative waste water treatment technologies are becoming increasingly important. Particularly challenging are high-salt waste waters or process waters, which often also contain significant loads of organic matter. For repeated use of the water, these organisms must be eliminated. However, due to the damage and inhibition of the microorganisms associated with the high salt load, no cost-effective conventional biological aerobic or anaerobic process can be used. Thus, treatment is currently often complicated and expensive.

Technological approaches

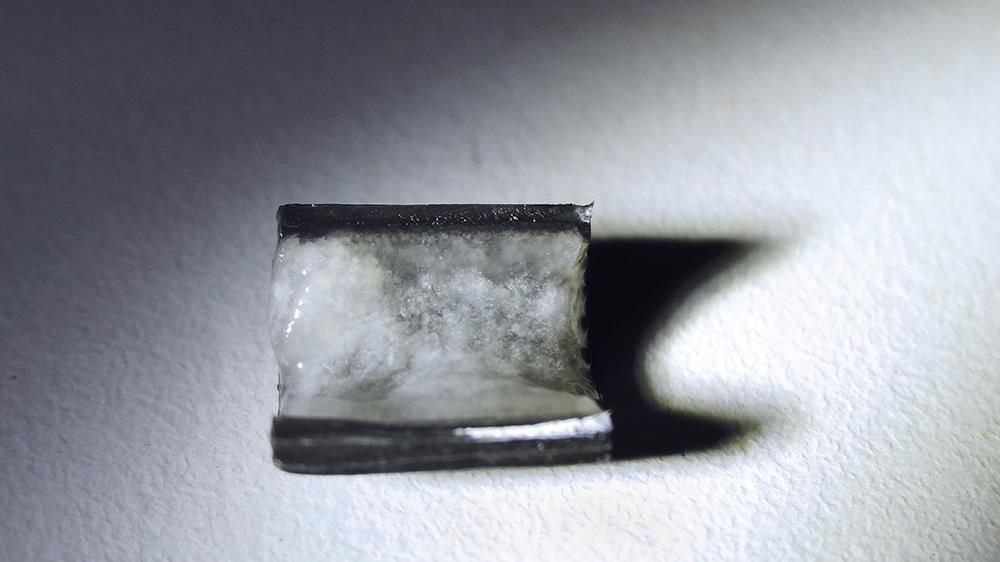

Within the framework of several industrial projects, researchers at IKTS have developed and tested specific process combinations that enable the industry-specific process waters to be thoroughly cleaned despite the high salt concentrations, for example in waste water from pulp production (carboxymethylcellulose and methylcellulose), silicone chemistry, ion exchange and membrane production, as well as from the food industry. Each of these industry-specific waste waters has its own material composition. Therefore, IKTS offers a very broad range of technological approaches for economical and secure solutions for the customer. For example, in addition to conventional/traditional processes used for the anaerobic and/or aerobic reduction of organic pollution in submersed, fixed and suspended bed systems, newer methods also include physicochemical processes, such as ceramic-based membrane filtration, combined with chemical (precipitation, extraction) and thermal (evaporation, stripping) processes for the reduction of nutrients. In addition, special photo-, sono- and electro-oxidative processes, and electrodialysis based on special ceramic high-performance components are also part of the competence portfolio of IKTS.

Thus, IKTS has extensive, practical process know-how, many years of experience and the necessary material expertise to provide customer- and industry-specific solutions for the economic treatment of complex industrial process waters, even where conventional technologies fail due to high salt loads.