The one major purpose of any electrical characterization of commercial battery cells under application-specific test conditions is to find and clarify fault mechanisms. To achieve this purpose, Fraunhofer IKTS is able to apply typical load cycles of the most varied applications – from the drive cycle to testing according to international standards – in its cells. Such tests allow, on the one hand, to obtain data on the power density, cycle stability or internal resistance of the battery cells, and to use these for benchmarking. On the other hand, they provide insight into the quality of the manufacturing process. When it comes to special questions, the "Cell Design and Testing" working group can also develop and build customized test set-ups.

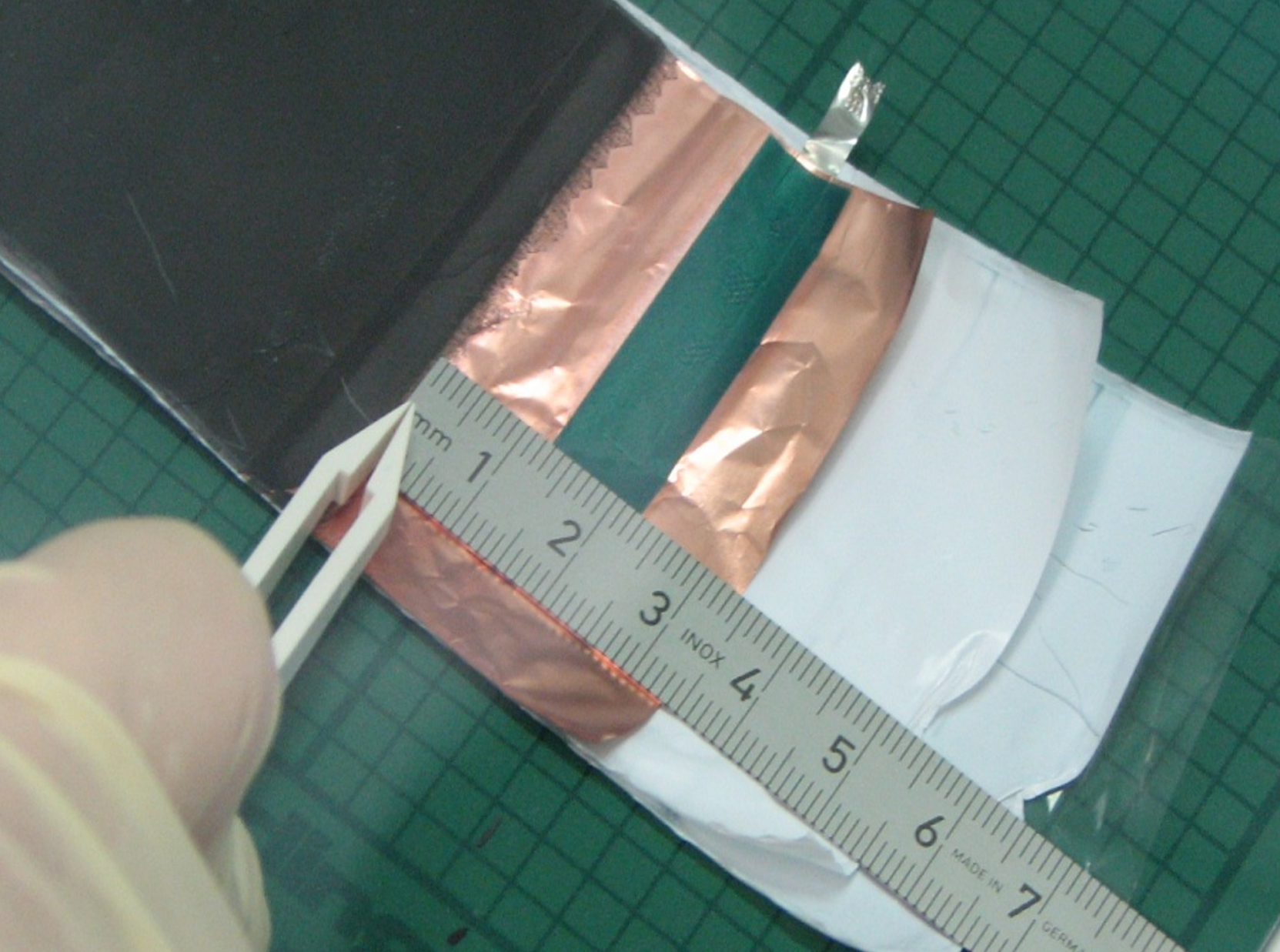

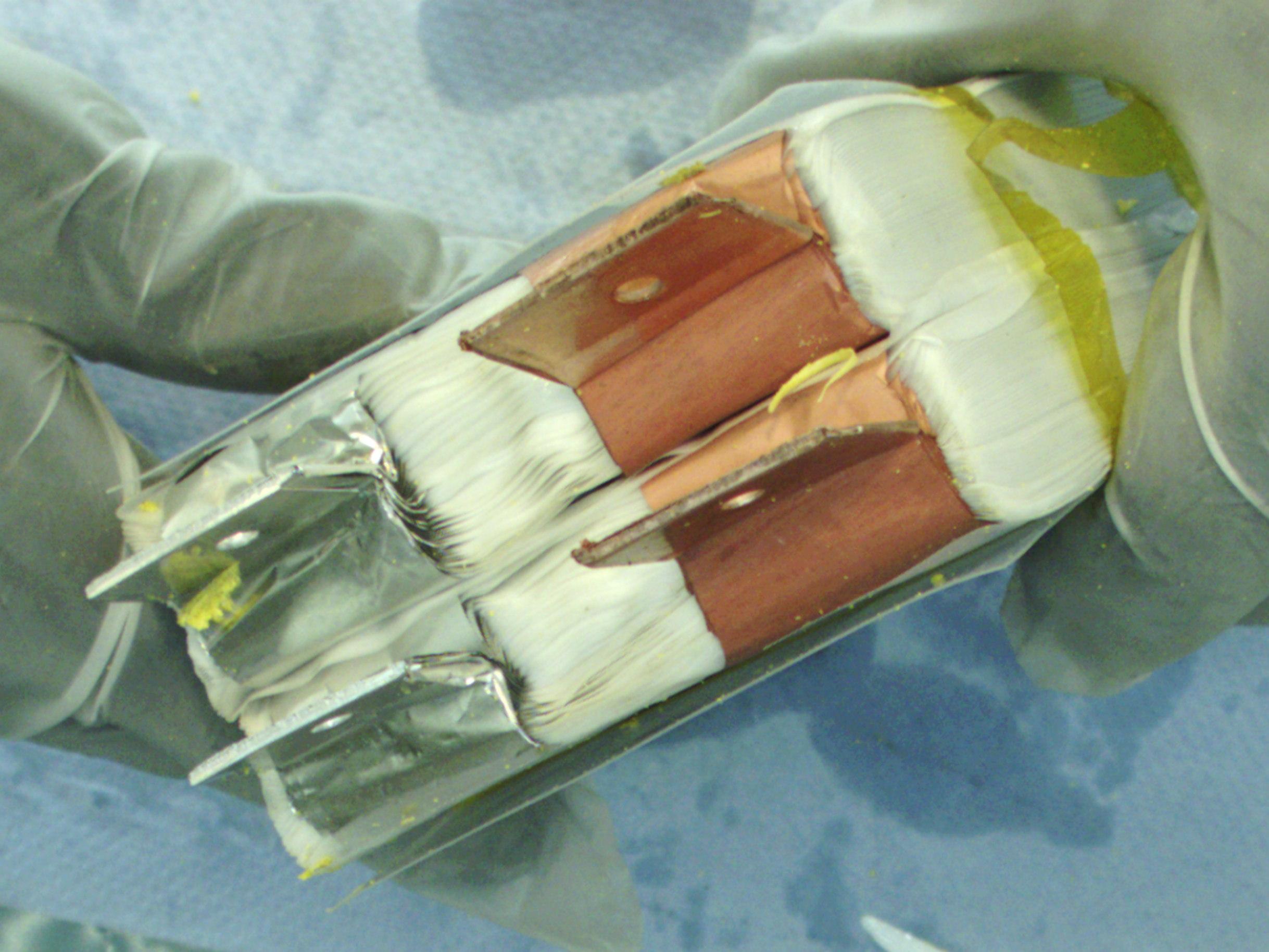

These set-ups are complemented by electrical investigations through the post-mortem analysis of battery cells to clarify degradation and fault mechanisms. Commercial cells up to 500 Ah are opened in a glovebox in inert atmosphere. This can be preceded by non-destructive computer-tomographic imaging used to document the position of components. When opening the cells, documenting the process in detail, recording irregularities in the cell structure and taking samples for material analysis are all paramount. To achieve all this, the researchers use imaging methods such as light, scanning electron and atomic force microscopy combined with analytical methods such as energy-dispersive X-ray and Raman spectroscopy, BET or DSC measurement. Furthermore, it is possible to electrochemically characterize extracted electrodes in test cells, for instance in order to analyze the various degradation effects of anode and cathode.

Services offered

- Investigations with impedance spectroscopy and cycle tests on battery cells up to 400 A

- Investigation of performance and aging properties in climate-controlled conditions (-20 to 60 °C)

- Post-mortem analysis of battery cells of various formats and sizes (experience with handling cells up to 500 Ah) in argon atmosphere

- Development of various transfer devices for transport between glovebox and analytical equipment

- Computer tomography on cells