Process digitization in the metal industry

Current research

For the digitization of production processes, the individual identification of the manufactured components is a prerequisite as production parameters and component condition can only then be combined. Particular challenges arise in metal processing. While cold-manufactured metal components are being marked since a long time, high process temperatures of over 1000 °C prevent consistent marking of other components. The melting of surfaces, tarnishing, scaling and potentially occurring corrosion make conventional marking methods impossible in many cases.

The Ceracode® technology

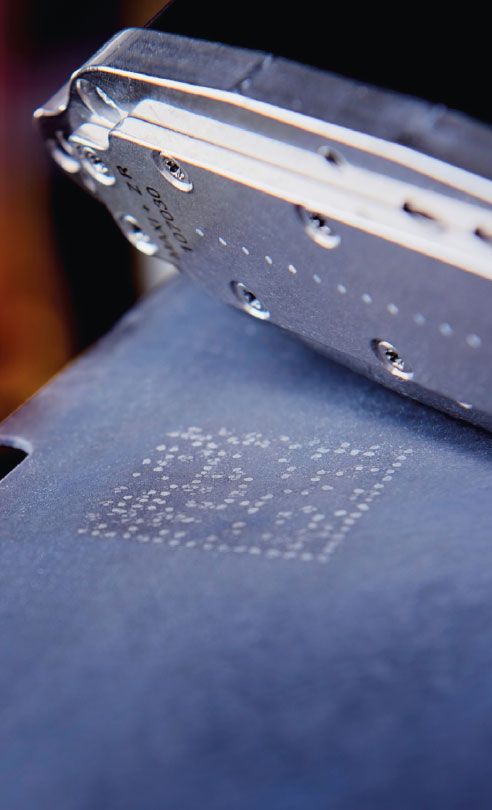

For these difficult applications, Fraunhofer IKTS has therefore successfully developed the high-temperature Ceracode® ink, which is marketed by the IKTS spin-off Senodis Technologies GmbH. This ink is used to print markings (such as data matrix codes) on metal components using standard industrial printers, before these are further processed in high-temperature steps. The high temperature causes the ink components and the metal surface to bond, resulting in a permanent marking. The marking is already being used for press hardening in production lines at automotive manufacturers. This forming technology is used to produce high-strength crash-relevant body elements, like A, B, C pillars or battery boxes.

The marking process has passed the stage of technology development and is available as a product of the marketing partner. Against this background, Fraunhofer IKTS is now tackling new applications that go beyond the pure component identification (track-and-trace).

Opening up new applications in process digitization

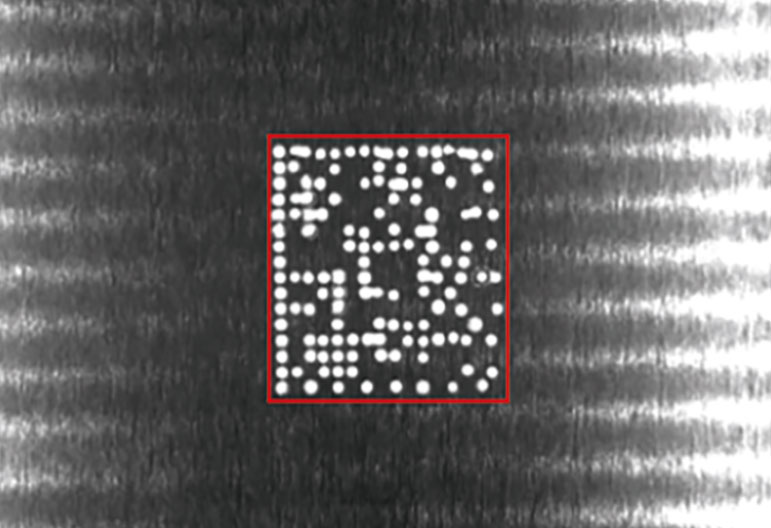

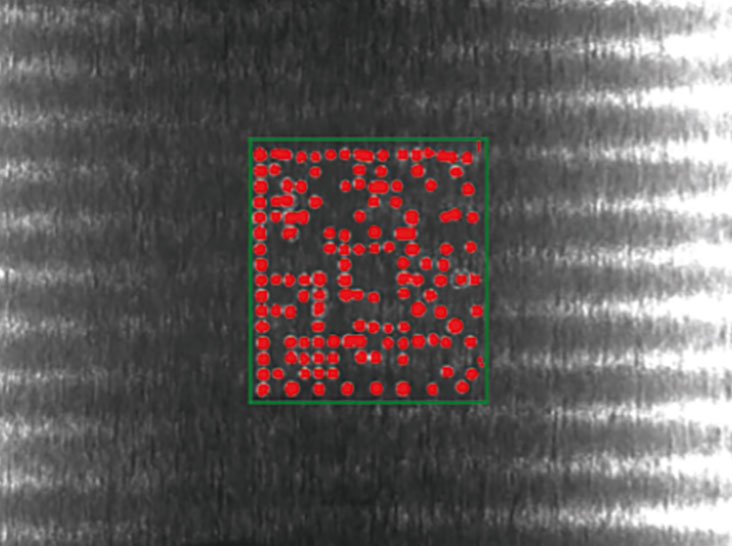

In addition to recording the code content (e.g. serial production number), the identification allows process parameters (like furnace dwell times, press forces, tools used) to be assigned to individual components. Thus, the granularity of process digitization is increased and can be used for optimization via the digital twin of the production process. On the other hand, the marking process itself can be monitored and thus made highly reliable by automatically analyzing the print image immediately after printing.

Fraunhofer IKTS and Senodis are pursuing the latter together in the BMWK joint project “Ceracode Digital” (grant no. 16GP105802). Automated image segmentation (differentiation between print pattern and background) makes it possible to detect smallest individual deviations, e.g. print dots deviating from their target position. The characteristics of the print determined in this way allow print failures to be detected and prevented at an early stage. In addition, it can also be used to verify the authenticity of components, which will be of great relevance in the future, e.g. for recording component-specific CO2 footprints.

Sponsored by