Intelligent signal processing is required in mechanical engineering for process-integrated quality control, for operating life analyses of wear parts and for condition monitoring. For this reason, Fraunhofer IKTS developed a system for intelligent signal processing in the BMBF joint project "MiSIS" together with its partners.

DSP and FPGA – heart of the miniaturized system

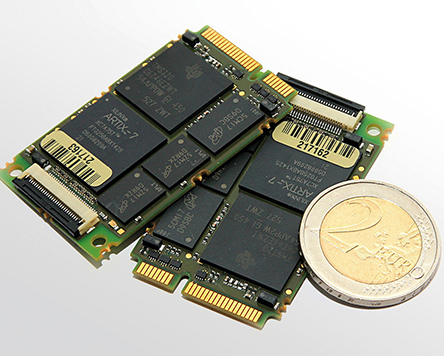

The base module of the intelligent hardware consists of a digital signal processor (DSP) and a field-programmable gate array (FPGA) along with the required memory, power supply, and peripheral interfaces. The module in the form of a mini PCI express card (30 x 50.95 mm) can be operated in various systems, e.g. in laptops or tablets. The combination of DSP and FPGA allows for the realization of complex, real-time critical algorithms up to acoustic pattern recognition with deep neural networks (DNN) or hidden Markov models (HMM). The base module can be connected to various signal acquisition and signal output modules via flat ribbon cables. This makes it suitable for audio and ultrasonic signal processing as well as processing of other signal sources.