Fraunhofer IKTS has many years of experience in the development of highly miniaturized passive ceramic valves. These are particularly suitable for applications in harsh environments such as at elevated temperatures or in chemically aggressive and volatile media. For example, miniaturized fuel cells are supplied with reaction gases via passive ceramic valves.

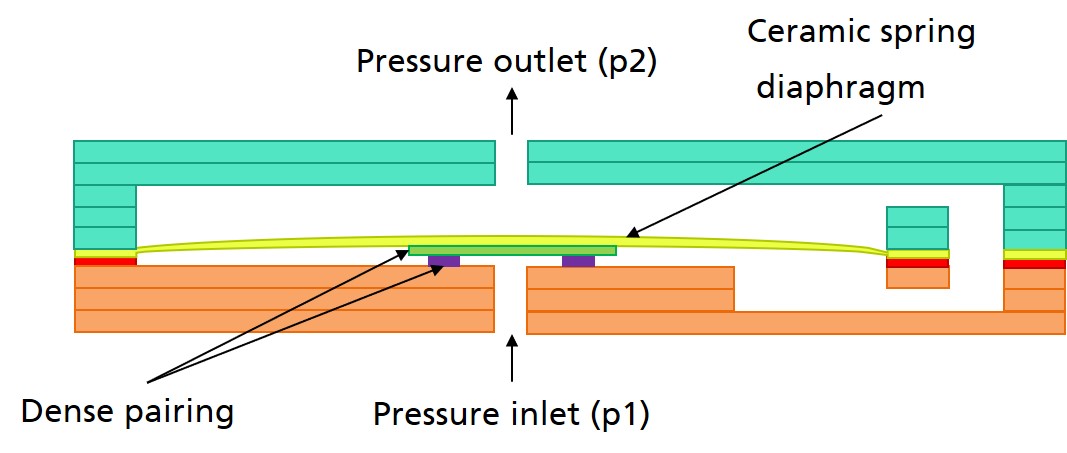

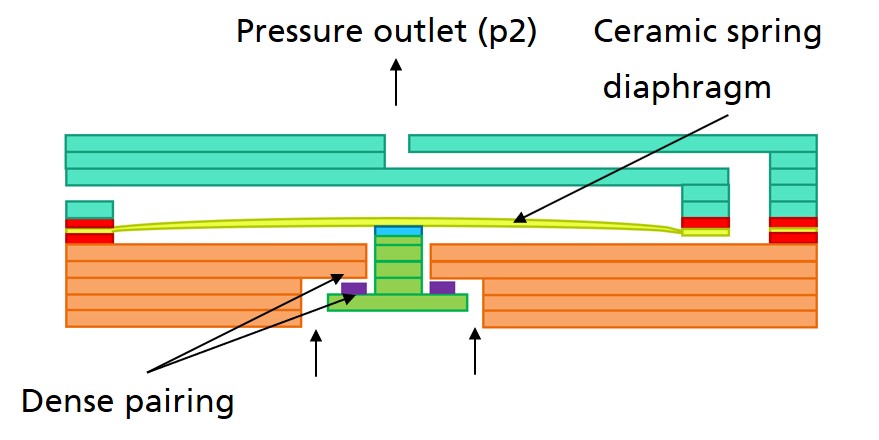

The ceramic multilayer technology (LTCC, low temperature cofired ceramics) serves as an integration platform also offering the possibility of 3D valve structuring and cost-effective series production. At Fraunhofer IKTS, a complex manufacturing process has been developed for LTCC valves and optimized with regard to its process stability. Depending on the application, the ceramic valves are designed and implemented in various designs. The ceramic valves are characterized in a suitable test stand under simulation of various climatic conditions and pressure loads up to 200 bar.