Optical coherence tomography (OCT) was originally developed for in-depth visualization of biological materials. However, thanks to intensive research, it has gained traction in other areas of application outside of medicine.

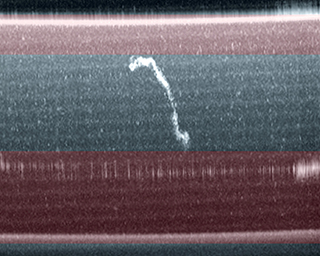

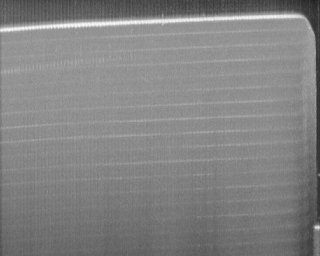

At Fraunhofer IKTS, OCT is used for the three-dimensional imaging of the most varied material structures, such as ceramics, (glass-fiber-reinforced) plastic, glass or biological materials. OCT enables real-time testing without direct contact with the sample.

The working principle of optical coherence tomography (OCT)

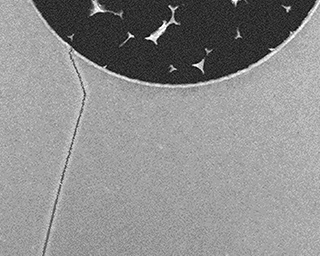

OCT, as a non-invasive, tomographic method, makes it possible to visualize the topography of surfaces and internal structures in scattering media. For this purpose, the studied object is irradiated with wide-band, near-infrared light and the scattered light is processed through a spectrometer. The potential resolution achieved by OCT is between two and 20 µm. OCT is also characterized by its high measuring speed. Volumetric studied areas can be scanned within a few seconds.

Fields of application of optical coherence tomography (OCT)

The Characterization Technologies workgroup offers application-specific OCT studies for the packaging, plastics, electronics, solar and food industries. Furthermore, the researchers develop client-specific OCT test systems for lab operation, product testing and process monitoring.

In the medical context, pharmacological products and various biomaterials are characterized, e.g. from the fields of dermatology, or ear, nose and throat medicine.