Author / video: Annegret Kolarow

#diensttalk with scientist Dr. Olga Ravkina on energy efficiency and green ammonia

The Tuesday feature. In the #diensttalk series, our employees give a brief insight into their activities and reveal what vision drives them.

Dr. Olga Ravkina has been a group leader at the Fraunhofer IKTS site in Hermsdorf for two years. Together with her team, she develops materials, components and processes for gas separation at high temperatures and for heterogeneous catalysis. Among other things, she is working on one of the most widely produced chemicals in the world.

You are in charge of the High-Temperature Membranes and Storage Materials group at IKTS. How did you get involved in this research area and what excites you about your work?

I studied chemistry at Leibniz University in Hannover and already worked on thermoelectric materials in my diploma thesis. At that time, it was mainly about producing CO2-stable materials for oxygen separation. That's how I came to this field, and I still find it interesting to develop new materials and work on new processes.

The exciting thing about our research field is that we are working on many current issues in the field of energy. We are trying to optimize processes. We don't just look at the material here, but really go into depth and design the processes to be energy-efficient. I'm fascinated by the fact that you can specifically modify the materials depending on the application. In percentage terms, we only change a few atoms in the structure and can achieve very different properties as a result.

»We don't just look at the material here, but really go into depth and design the processes to be energy-efficient."

A current research project deals with the synthesis of ammonia. What is the relevance of this chemical and how is IKTS involved?

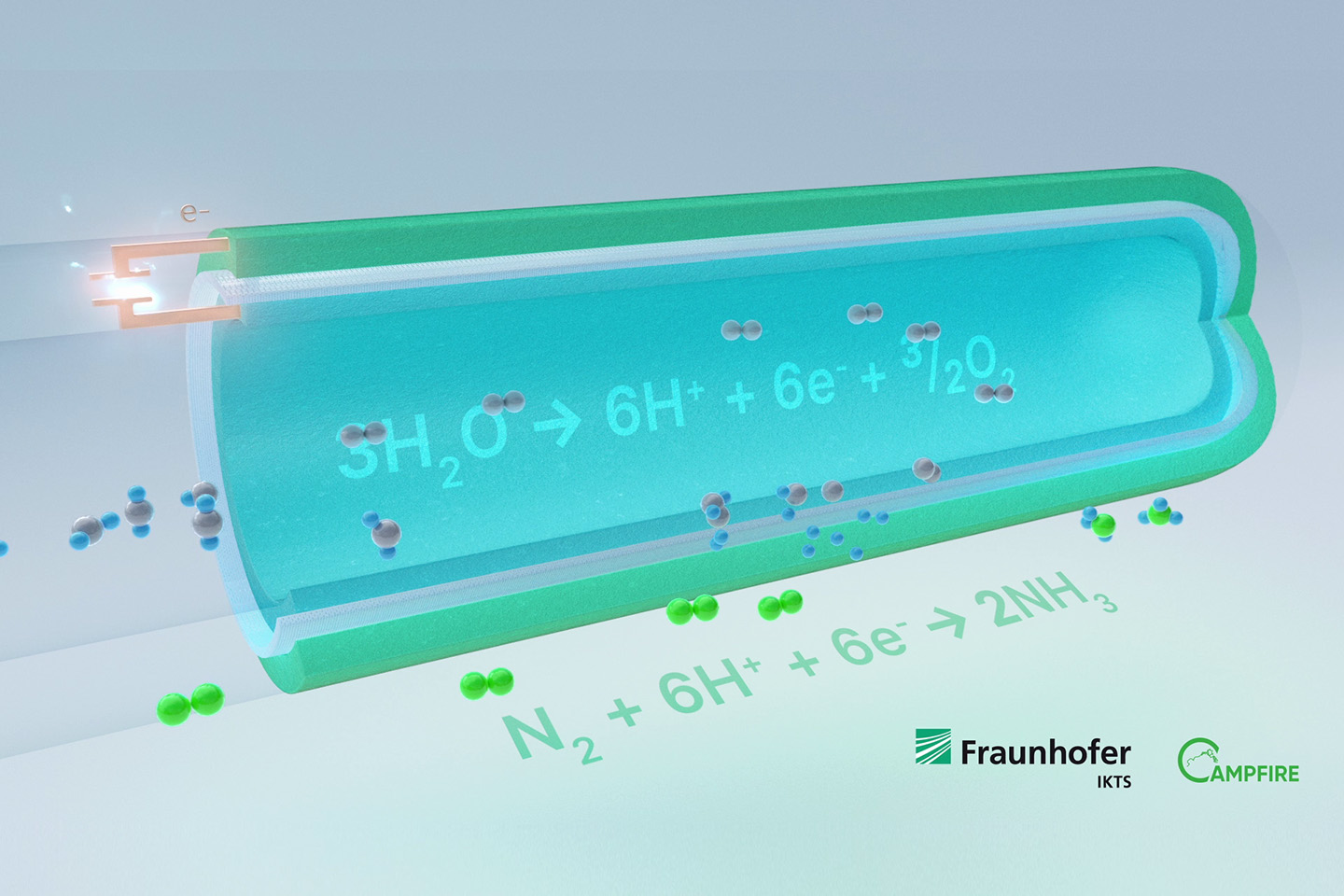

Ammonia is one of the most widely produced chemicals in the world. It is used as a fertilizer in agriculture and as a basic raw material in the chemical industry. However, its usual production is associated with the generation of climate-damaging greenhouse gases. In the CAMPFIRE 04 project, funded by the German Federal Ministry of Education and Research and cooperation with the Leibniz Institute for Plasma Science and Technology (INP), the Leibniz Institute for Catalysis (LIKAT) and the Hydrogen and Fuel Cell Center ZBT we are developing an alternative, more environment-friendly synthesis route for ammonia. In doing so, we want to use renewable energies to produce ammonia electrochemically via so-called solid-state ammonia synthesis, which involves the conversion of atmospheric nitrogen and water in a membrane reactor. In the project, Fraunhofer IKTS is developing a tubular ceramic carrier that is porous and thus gas-permeable. A thin-film membrane is applied to this support, which is proton-conducting and ensures that only the protons (H+) from the water pass through the membrane. On the other side is a catalyst. This is where the actual synthesis reaction takes place. In this way, we produce green ammonia, which can be used, for example, as an emission-free fuel in shipping.

What do you enjoy about working in your team and what benefits does Fraunhofer offer you?

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyDr. Olga Ravkina researches ceramic materials and processes for gas separation, such as an eco-friendly ammonia synthesis route.

We are a mixed team of scientists and also technical and laboratory staff, all of whom contribute their expertise and their experience, in order to achieve the best possible result. I find it very exciting and also very important that at Fraunhofer one has the opportunity not only to develop things on a laboratory scale, on a smaller scale, but also to upscale the processes. In other words, you can really test how it will work in a real-world scenario. What needs to be adjusted? How do you design the entire scale-up process? I think Fraunhofer is the only place where you really have these possibilities.

About the »CAMPFIRE« consortium

The CAMPFIRE consortium was created with support from ‘WIR! – Change through Innovation in the Region’, a funding programme financed by the Federal Ministry of Education and Research (BMBF). The goal of the consortium is to research and develop new energy conversion and storage technologies based on green ammonia for the energy system of the future. A long-term objective is for small and medium-sized enterprises (SMEs) in the region of Northeast Germany to establish pathways for the utilisation of advanced technologies that can be exported to other areas. CAMPFIRE technologies produced in the Northeast will facilitate the development of an energy economy based on green ammonia and a carbon-free, secure energy supply in the Baltic Sea Region, in Europe, and abroad. In the long term, the consortium aims to develop effective and cost-efficient methods to reduce the global carbon dioxide levels in the Earth’s atmosphere..

Further Information

- IKTS group "High-Temperature Membranes and Storage Materials"

- Tubular membrane-electrode assembly for solid-state ammonia synthesis

- Project "CAMPFIRE"

Here you can find more #diensttalks. Take a look behind the scenes of Fraunhofer IKTS.

Also stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.