Iodine as a low-cost fuel for small satellites – Fraunhofer IKTS contributes material competence to iFACT project

In the future, an extremely simple and robust electric drive shall be used to transport small satellites through space at low cost – using the fuel iodine. In the iFACT project, European researchers want to develop an iodine-based ion propulsion system and conduct extensive material tests over the next two years. Their aim is to establish an iodine-material compatibility library and an efficient European ground test infrastructure.

Even today, probes and satellites in space are often controlled electrically with an ion drive. However, the noble gas xenon used for this purpose is quite expensive and must be carried in pressurized tanks, which poses a safety risk, especially during rocket launches. Iodine could be an attractive alternative: it is solid and therefore compact, easy to transport, inexpensive and easily ionizable. Researchers hope that this will not only lead to fuel cost and volume savings , but also to a significantly smaller and lighter propulsion module. Thus, there could be provided more space on board for scientific instruments. However, there is still a lack of data on how iodine behaves with the materials used in the propulsion system and how the fuel can be fed in efficiently.

This is where the EU project iFACT (iodine Fed Advanced Cusp field Thruster) comes in

Under the leadership of Airbus Germany, the project, which is funded by the European Commission with two million euros under the "Horizon 2020" program, brings together the seven European partners Airbus France, EASN-TIS (Belgium), University of Southampton (UK), Fraunhofer IKTS (Germany), Aerospazio Technologie (Italy), Justus Liebig University Giessen (Germany), and EnduroSat (Bulgaria). Over the next two years, they plan to develop an iodine-optimized feed-in architecture for the "Advanced Cusp Field Thruster" electric drive principle. One of the core elements of this project is the testing of iodine-compatible cathodes and neutralizers.

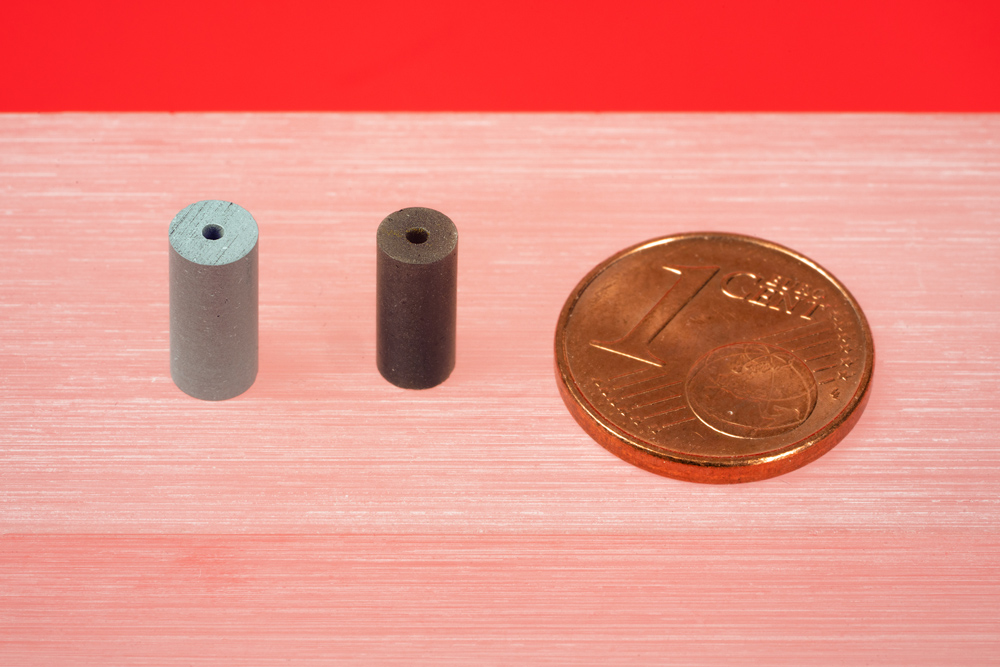

The Fraunhofer IKTS is contributing its material competence in the manufacture of electron-emitting ceramics as cathodes to the project. "Our aim is to improve the ceramic components developed at Fraunhofer IKTS in terms of low work function and high current density so that they deliver the best possible performance in combination with the fuel iodine," explains Dr. Katja Wätzig, researcher at IKTS. "To this end, we will modify the chemical composition of the material and have it tested by the project partners with a view to its application".

In addition to investigations on the drive components, further material tests by the research partners on the effects of iodine corrosion on the satellite platform are planned. The project will also develop and experimentally validate test systems in various power classes from 10 W to 1000 W.

An ion engine is reminiscent of a hair dryer from which a warm air stream emerges

The only difference here is that iodine ions exit the engine and generate the thrust. First of all, the iodine stored in a solid state must be vaporized. The electron-emitting ceramic (C12A7) serves as cathode and ionizes the iodine. This produces positively charged iodine ions, which are accelerated by an electric or electromagnetic field and thus provide the thrust. After leaving the engine, the positively charged iodine ions are neutralized again by adding electrons to the current to prevent a negative electrical charge on the satellite.

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement Nr.870336.