Quick introduction: Foundry

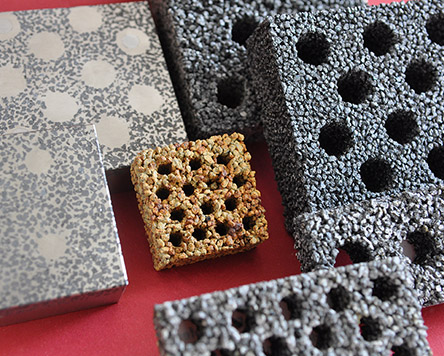

Despite the wide range of materials available, the use of cast metal parts is limited in terms of strength, rigidity or wear resistance. With the help of porous ceramic inserts – so-called preforms – their application possibilities can, however, be expanded and their service life extended. The advantage of using preforms lies in the fact that they are only positioned in the component where they are exposed to high stresses. This means that the entire workpiece does not have to be covered by ceramics, which ensures good machinability and also enables inexpensive production. At Fraunhofer IKTS, these preforms are developed and manufactured from particle-sintered ceramics and ceramic foams. A wide range of ceramic materials can be used, which can be selected and further developed depending on the application. The high geometric variability of both preform variants is particularly advantageous here, so that both very small preforms and extremely large components can be produced.

The sintered porous grain preforms can be composed of both fine and coarse particles and have comparatively high ceramic proportions of up to 50 %. Due to their structure, they are particularly suitable for applications requiring high wear resistance and long service lives. In addition, they can be infiltrated with various cast metals in gravity cast iron materials and do not require any special casting processes. The foam-ceramic preforms are a further development of the classic casting filters used for the filtration of molten metals. However, they have significantly higher ceramic contents of up to 30 % and a special rough surface in order to achieve a particularly good interlocking of preform and metal. These foam-ceramic preforms are very well suited for reinforcing light metal alloys, for example to produce higher stiffnesses. They are preferably infiltrated by die casting with metal alloys. As an alternative to ceramic foams, metal foams can also be used, for example made of steel, which are also being developed at IKTS.

Very important for the properties of the cast components is the formation of the contact surface on which the ceramics and metals collide. This must always be adapted to the respective material combination of metals and ceramics, which is achieved by designing special ceramic surfaces.

Through the cooperation established at the IKTS with various foundries, it is possible not only to manufacture preforms but also to further develop composite materials with regard to application-oriented material combinations.