Continuous fiber coating for composite materials

Current research

Fiber-reinforced composites are used in many areas of industry because of their diverse properties and varied design possibilities. The fibers perform different functions depending on the application. Regardless of the type of composite, the fiber-matrix interface plays a crucial role in adjusting the composite’s properties. Defined fiber coatings open up a wide range of possibilities for adjusting properties, and therefore functions. Coatings can be applied to increase the strength of the fiber‘s bond to the matrix material, and protection from chemical interactions during infiltration with the matrix material can be achieved. The combination of continuous fibers, e.g. those made of glass or carbon, with a ductile matrix, e.g. from plastics or metals, serves mainly to improve the strength and stiffness of these materials. In contrast to this, Fraunhofer IKTS focuses its research on ceramic fiber composites with high fracture toughness and damage tolerance.

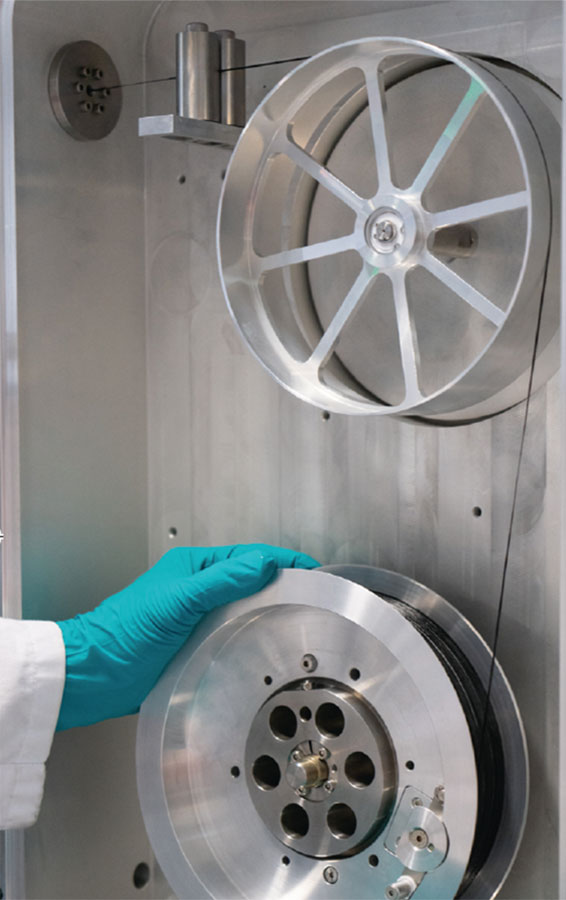

For this purpose, a coating system for chemical vapor deposition (CVD) has been set up at IKTS, with which manifold coating technologies and coating variants can be realized, using a 2-chamber reactor system in a roll-to-roll process (image 1 and 2). Both CVD coating chambers can be operated independently of each other with variable precursors at deposition temperatures of up to 1100 °C and coating pressures of up to 100 mbar in the CVD process. During the coating process, a fiber roving consisting of many individual filaments is continuously moving through both coating chambers using the roll-to-roll winding system.

CVD coating for fibers in ceramic composites

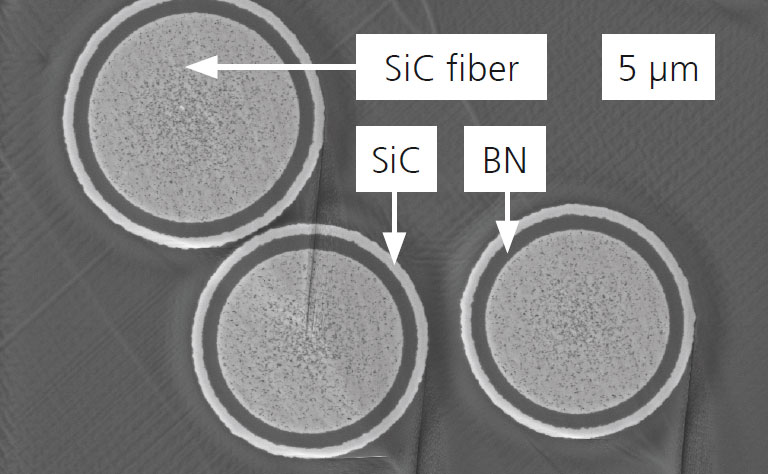

Ceramic matrix composites (CMC), which are used e.g. as lightweight materials or in high-temperature processes, require fiber coatings that ensure in particular (in addition to reliable oxidation and corrosion protection of the fibers) the composite’s damage-tolerant behavior. The fiber reinforcement helps to avoid the brittle material behavior that is typical for ceramic materials, thanks to crack deflection and fiber pull-out. For non-oxide composites, layers of boron nitride with a hexagonal layer structure (h-BN) are normally used, since they provide favorable pull-out conditions. However, these layers are not sufficiently stable at high temperatures (oxidation resistance at temperatures > 1000 °C) in air. For this reason, Fraunhofer IKTS has developed double layers consisting of an h-BN layer with a protective layer of silicon carbide (SiC) on top (image 3). These double layers can be applied in one single run together with the h-BN layer using the two-coating-chambers setup (single pass processing). Single fiber push-out tests show the desired weak bonding of the coated fibers to the matrix material.