Electromobility is an essential component for climate-friendly transportation. For further advance electromobility, development and production of reliable and durable batteries is essential. To meet future demand, sustainable process technologies for semi-finished products and raw materials (e.g. battery powder with minimized cobalt and CRM content) must be available in addition to manufacturing facilities for complete battery systems. Against this background, a coating technology is being developed at Fraunhofer IKTS that avoids or greatly minimizes the use of cobalt or other critical raw materials.

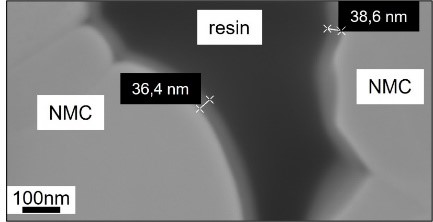

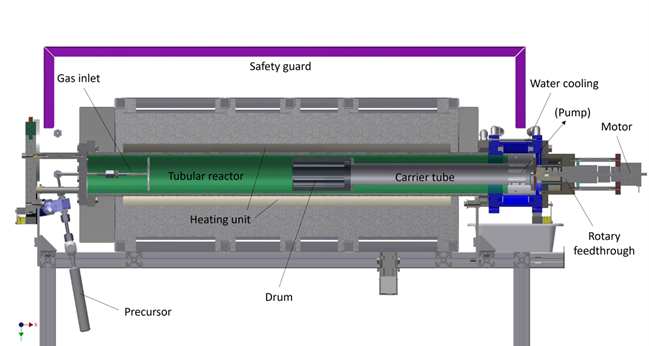

To this end, we are pursuing two goals in the current research project: On the one hand, the energy density and lifetime of batteries should be increased and, on the other hand, degradation of the electrolyte should be avoided by means of a suitable coating (by atomic layer deposition (ALD) and spray drying). To this end, we are investigating various coating materials in terms of composition and layer thickness and optimizing them with regard to their electrochemical properties.

Project title: Functional coating of battery powders

Funding: BMWK / IGF

Funding code: IGF 17/17 22233 BR

Project period: 01.04.2022 – 31.03.2024