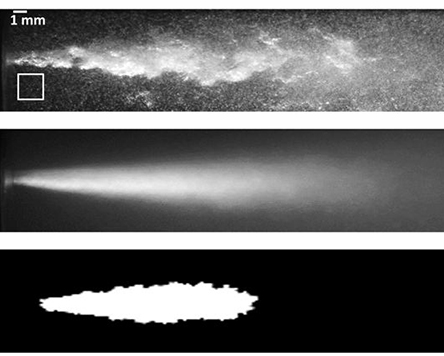

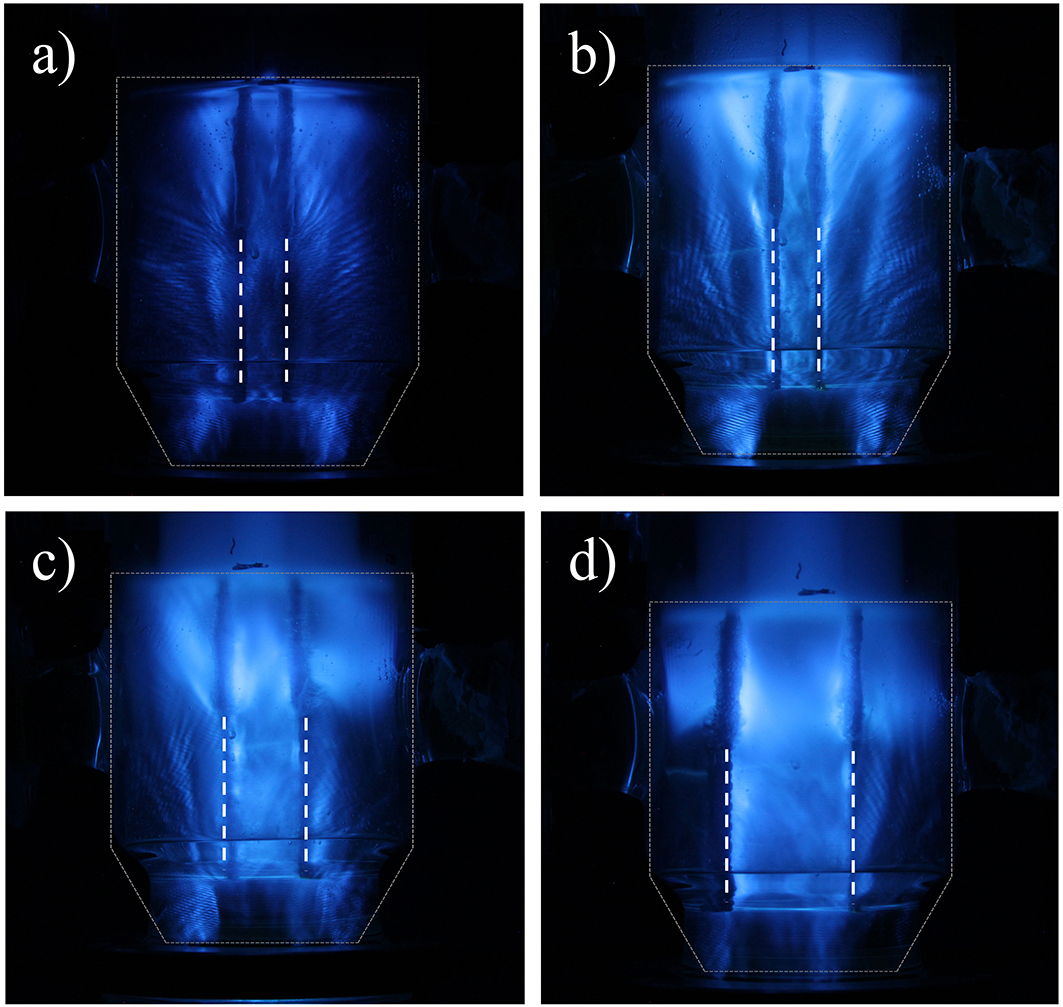

Cavitation processes have a variety of applications in environmental process engineering, where different processes can be initiated, activated or intensified. At Fraunhofer IKTS, various cavitation processes (hydrodynamic, acoustic, simultaneous) are being investigated for use in wastewater treatment, for example, and further developed with the aid of cavitation field analysis. This analysis uses optical or acoustic information and provides an insight into the qualitative and quantitative distribution of the cavitation fields in the reactor. Furthermore, methods are used to determine the temporally and spatially resolved bubble fields. With this information, bubble field and cavitation field can be correlated with the corresponding results (conversion, mineralization, particle size, etc.) and used for reactor design as well as process engineering design.

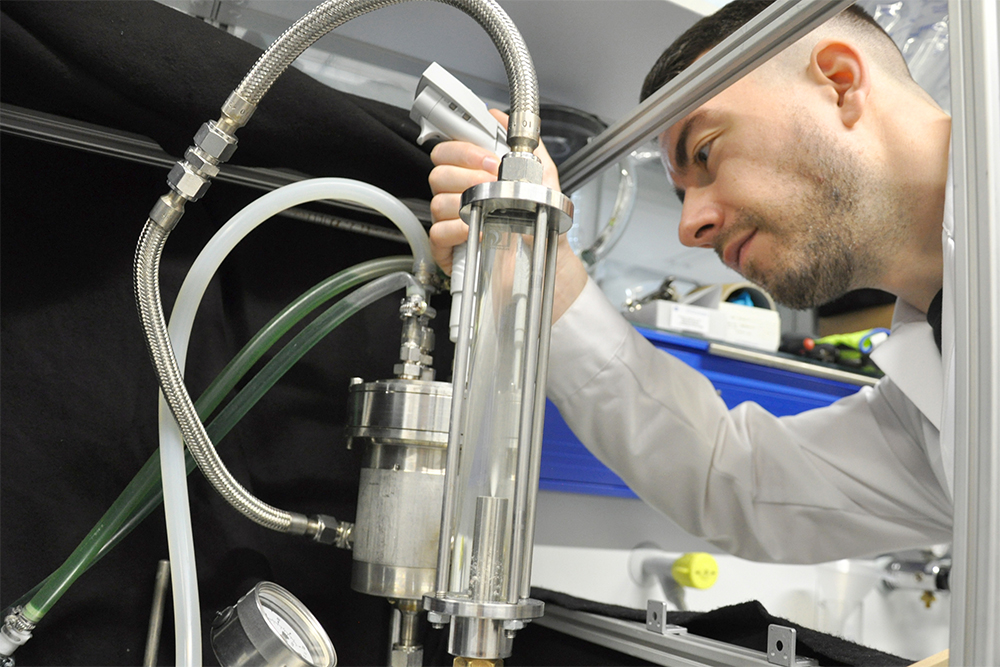

Fraunhofer IKTS designs, builds, tests and optimizes cavitation reactors for various application areas. This also includes the integration of sensor technology and a basic control and regulation of the plants (e.g. based on Arduino, Labview or PLC, with partners). In addition, industrial plants are designed and adapted together with companies on the basis of laboratory tests.

Services offered

- Investigation of hydrodynamic, acoustic and simultaneous cavitation processes by means of cavitation field analysis

- Design, process engineering, construction, test and upscaling of cavitation reactors

- Integration of sensors and controls