In technical processes there are many gas streams like product gases, intermediate gases (syngas, nitrogen oxides, hydrocarbons, biogas, wood gas) as well as VOC-containing waste gases (VOC - Volatile Organic Compound). Often heterogeneous catalyzed reac-tions are used for a further processing of these gases mainly based on fine dispersed novel metals in form of coatings on a ceramic substrate.

Ceramic catalysts are an interesting alternative because their activity and selectivity de-pend strongly on the chemical composition and can be easily adapted. In addition ce-ramic catalysts are cheaper compared to noble metal catalysts. Therefore not only coat-ings but also bulk materials can be used which can be simple manufactured. On this way the yield can be increased or the residence time can be minimized. In addition ce-ramic catalysts are much more stable against catalyst poisoning.

R&D-Topics

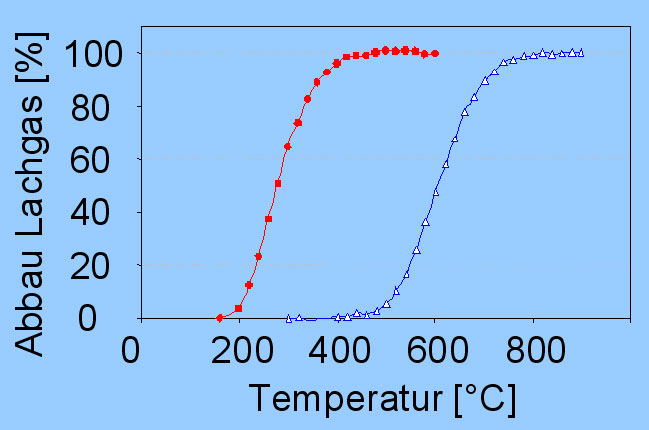

- Catalytic decomposition of specific components of industrial waste gases (e.g. N2O/HNO3 manufacturing, NOx/combustion) with the help of ceramic catalysts

- Total oxidation of VOCs of waste gases by using ceramic catalysts

- Partial oxidation and reformation in membrane reactors

- Combination of membrane separation and catalysis in membrane reactors

- Combination of oxygen storage and catalysis in fixed bed reactors

- Combination of ceramic catalysts with normal pressure plasma discharge