Battery development at the Fraunhofer Project Center ZESS

Current research

The Fraunhofer Project Center for Energy Storage and Systems ZESS is a joint research and transfer platform for the Fraunhofer Institutes IKTS, IST and IFAM, with four main areas of research: lithium solid-state batteries, stationary energy storage systems based on sodium-nickel chloride batteries, hydrogen technologies with high storage densities, and testing technology for quality assurance. The State of Lower Saxony has been supporting these activities since 2018.

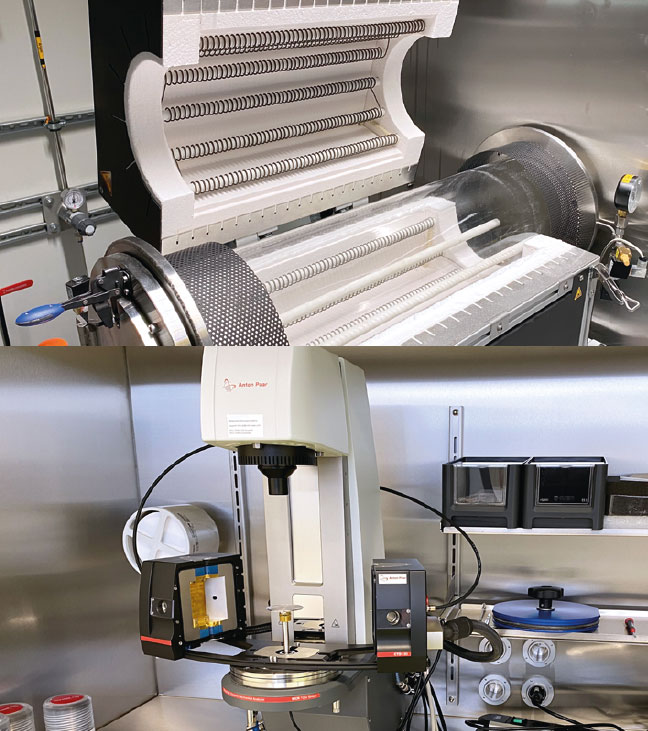

For the research into solid-state batteries, new laboratories have been designed and equipped at the Braunschweig site. These provide the infrastructure for the synthesis of electrolytes under inert atmosphere, the manufacture of electrodes and for cell assembly. The processes are analyzed using the appropriate testing technologies. These include, for example, calorimetric and rheological measurements, as well as laser light diffraction. These methods allow for the examination of air and moisture-sensitive materials. In 2023, a new building is planned that will house chemical and technical laboratories, a drying room as well as office space for 100 employees. This makes it possible to bring up the processes tested in the project center to technical scale.

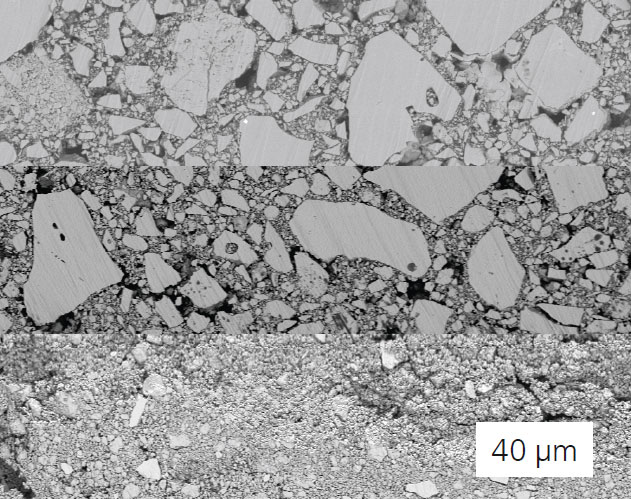

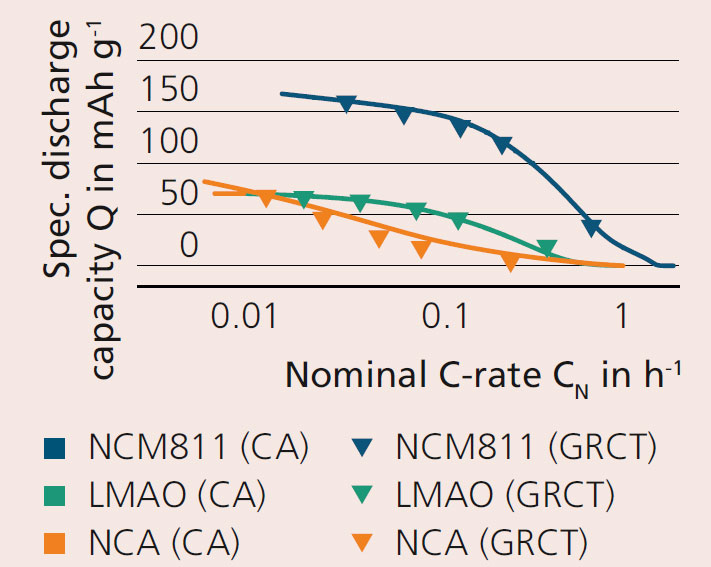

One research focus of Fraunhofer IKTS at ZESS is the development of sulfide-based electrolytes, including the testing of appropriate processing technologies and analytics. The evaluation of the electrodes serves to understand the connection between performance and material properties and thus the further development and optimization of the individual components. The crystal and particle properties must be adapted precisely to the requirements of the final composite. This makes it possible to match the electrochemical properties to the required properties of the solid-state cell. Furthermore, methods for the rapid characterization of these electrodes are being developed further. At ZESS, the method of chronoamperometry1, optimized for the respective materials, is used. This allows for the components to be examined for their performance properties more quickly and without loss of information, leading to increased efficiency for the research process.

Fraunhofer IKTS contributes its comprehensive expertise in the area of materials and process development for ceramic energy carriers to the four research areas at ZESS. The field of competence covers materials development and the manufacturing of components, such as electrodes and separators, as well as the design and development of complete battery systems. The main focus is always on scaling up processes for industrial manufacturing.

Literature

[1] S. Yanev, H. Auer, C. Heubner, K. Nikolowski, M. Partsch, A. Michaelis, Rapid Determination of All-Solid-State Battery Performance via Chronoamperometry, J. Electrochem. Soc. 169 090519.

Sponsored by