Non-contact determination of bio-mechanics of the eye through simulations

Current research

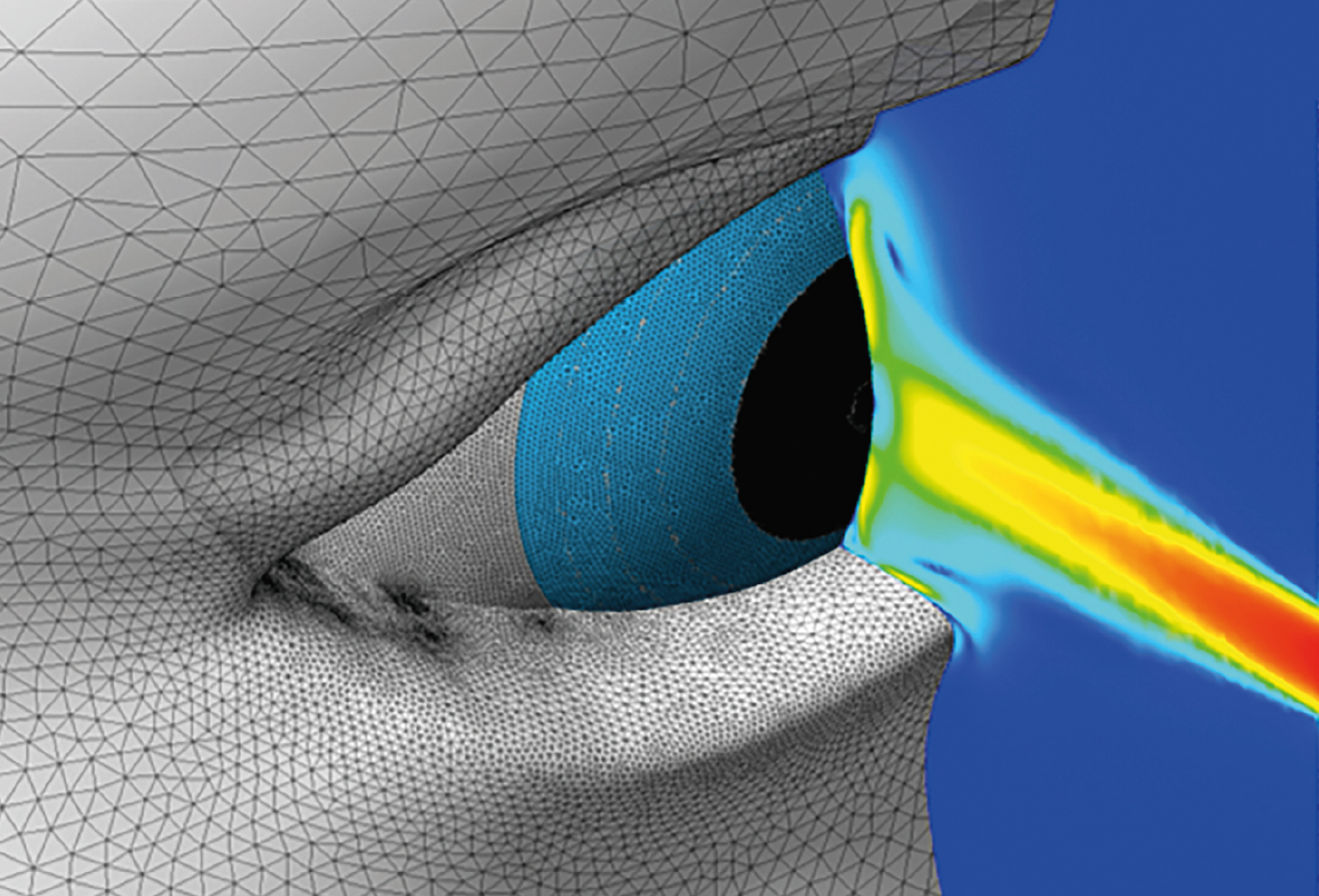

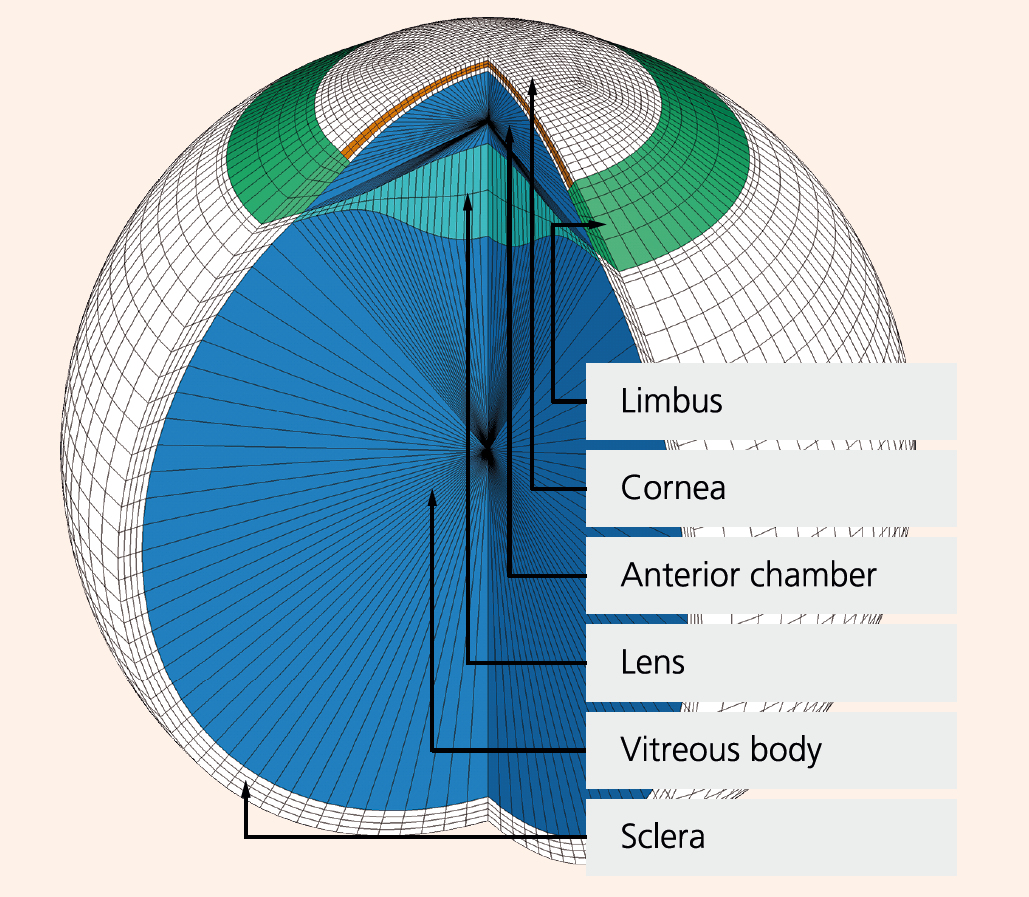

The biomechanics of the human eye are of threefold importance in medicine. They reflect pathological processes through biochemical changes in the tissue structure and are therefore suitable for diagnosing diseases. Conversely, they also enable the investigation of healing processes after surgery. The biomechanics of the eye envelope also affect the imaging properties and thus visual acuity. To facilitate the non-contact identification of material properties of the human eye, IKTS is partnering with Technische Universität Dresden and Ruhr-Universität Bochum in a joint research project. The research project is based on air pulse tonometry, which applies an air pulse to the eye and records the subsequent deformation of the eye with a camera system. If the deformation of the eye and the load required for the deformation is known, it is possible to draw conclusions about the material properties. This task is fulfilled by a numerical simulation based on the finite element method (FEM). It requires a realistic definition of the external loads, a detailed virtual model of the human eye and the use of a suitable material model. The loads generated by the air pulse tonometer must be determined experimentally in their qualitative distribution and with regard to their quantitative values. For this purpose, a glass eye is placed in front of the air pulse tonometer and its movement caused by the air pulse is recorded with the laser triangulation method. In connection with a flow simulation (CFD) the pressure pulse can thus be characterized and the influence of eye deformation and the eyelids on load distribution investigated. In order to accurately describe the complex structure of the eye envelope, which consists of cells, extracellular matrix and collagen fibers, a special material model was implemented in ANSYS with the UserMat routine. This model enables the modeling of incompressible and hyperelastic material behavior and also takes into account the position-dependent fiber orientation and statistical fiber scattering. In summary, it can be said that the method allows to identify unique material properties based on optical deformation measurements. The function of the method has already been demonstrated with predefined test cases. In future work, the current computing time is to be reduced from approx. 24 hours to almost real time. This makes the method practicable for use in the respective examination equipment directly on the patient.