Mechanical material data are determined based on destructive tests. Tensile and peel tests as well as pull and shear tests are available. The IKTS group "System Integration and AVT" can perform tests on high-performance electronics up to 600 °C and thus simulate performance and lifetime under harsh environmental conditions.

Mechanical Special Measurement Methods for High-Performance Electronics

Topic

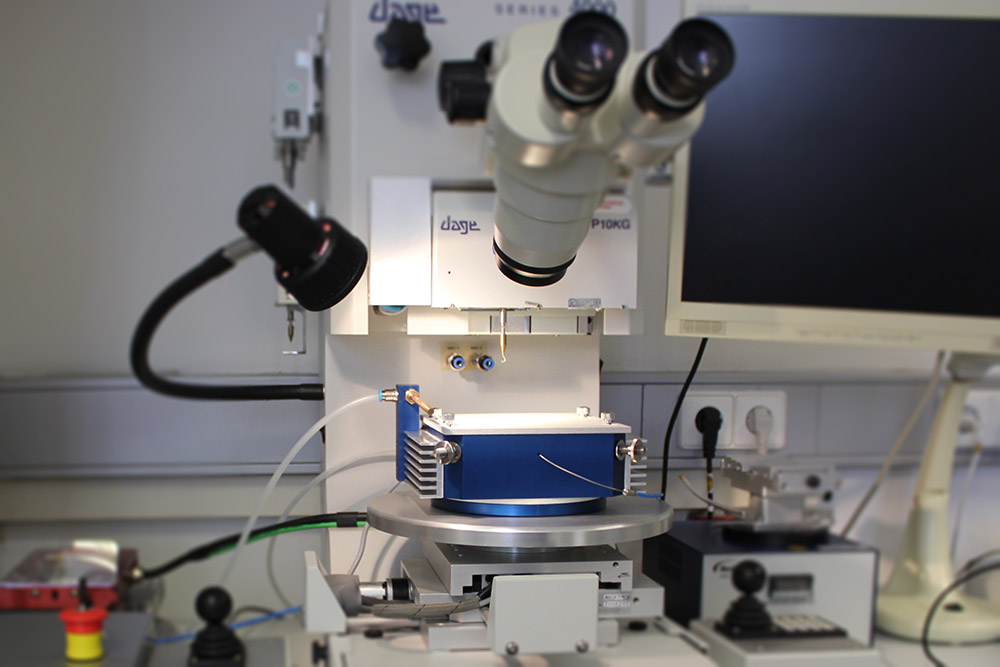

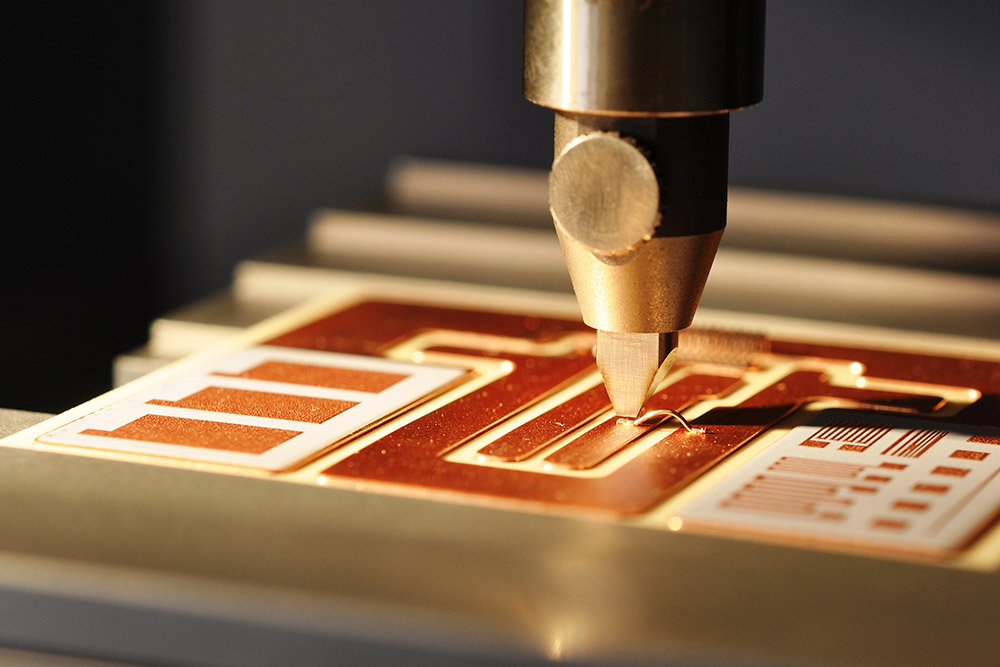

Pull tests on wire bond interconnects

Pull tests are used to characterize wire bond interconnects. During the test, a pull hook is driven under the bond loop and the loop is pulled off with a constant force. The force required to destroy the connection as well as the resulting fracture pattern is considered a quality characteristic. The pull tests are carried out at Fraunhofer IKTS based on the DVS 2811 test standard. As a standard, the wire bond interconnects are tested before and after a targeted accelerated aging.

Based on a self-developed device extension, the scientists at IKTS have the possibility to position small-sized samples in a heating chamber. This allows special pull tests to be carried out at sample temperatures up to 600 °C.

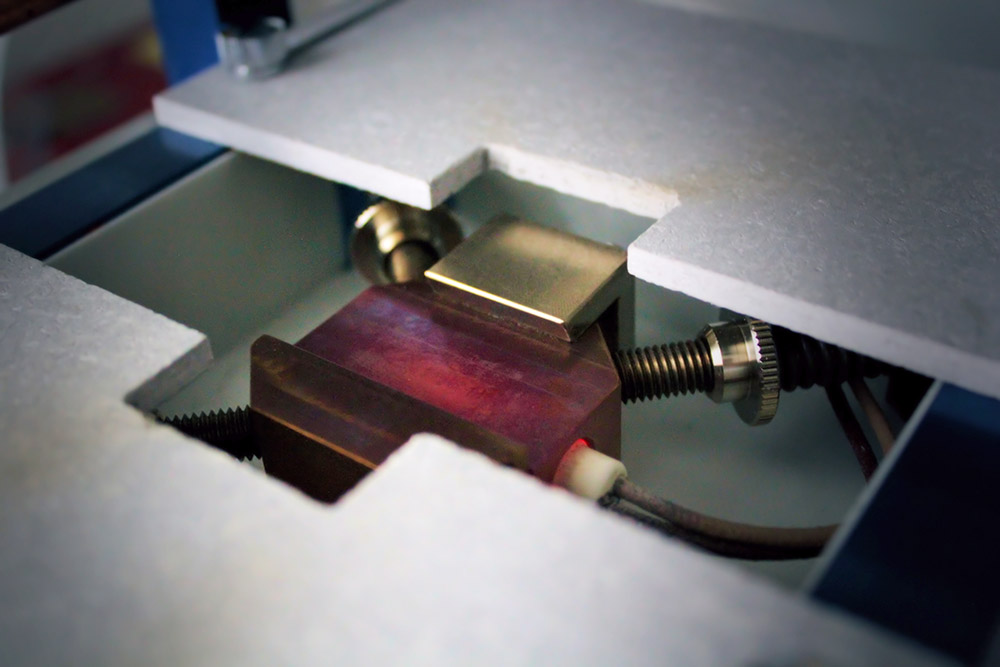

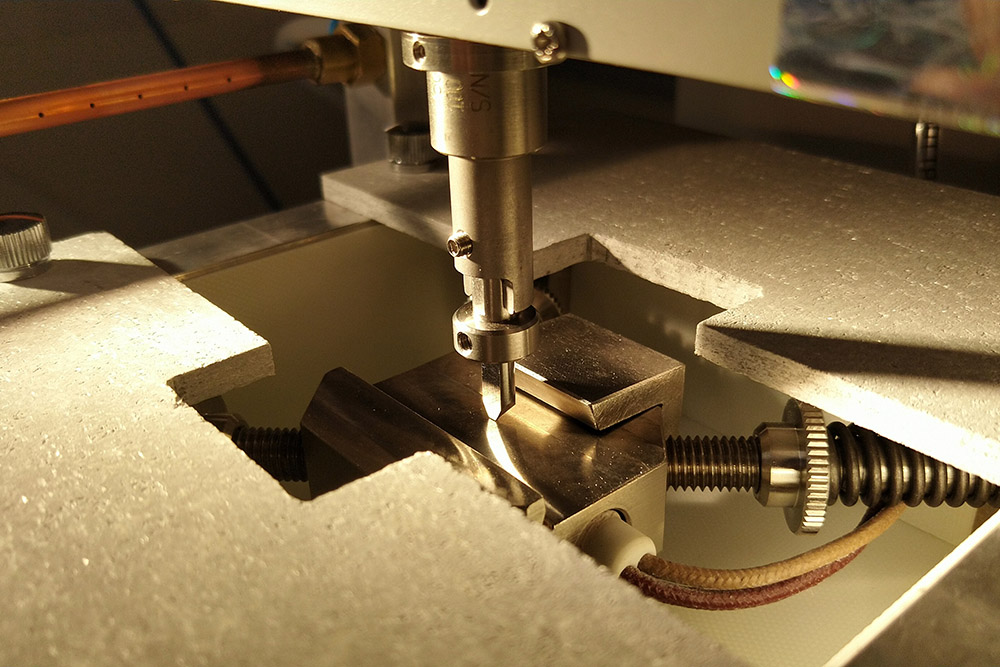

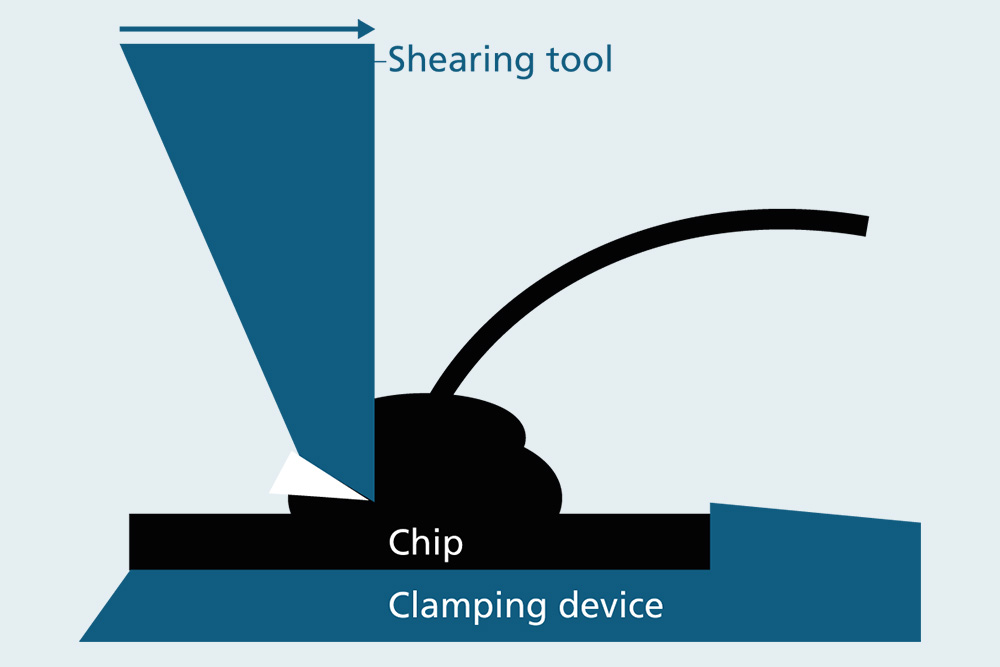

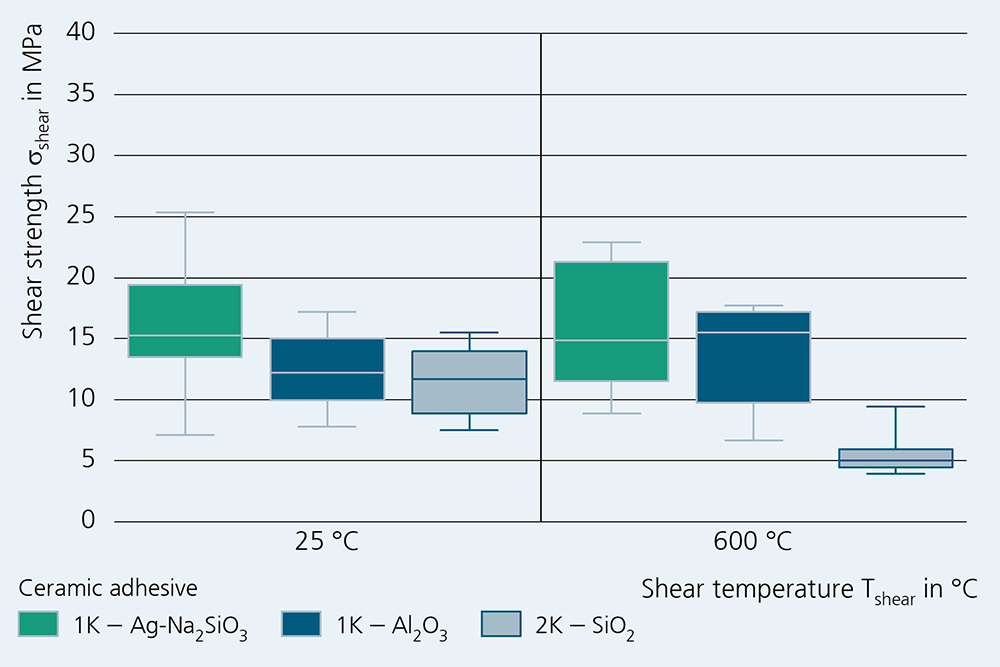

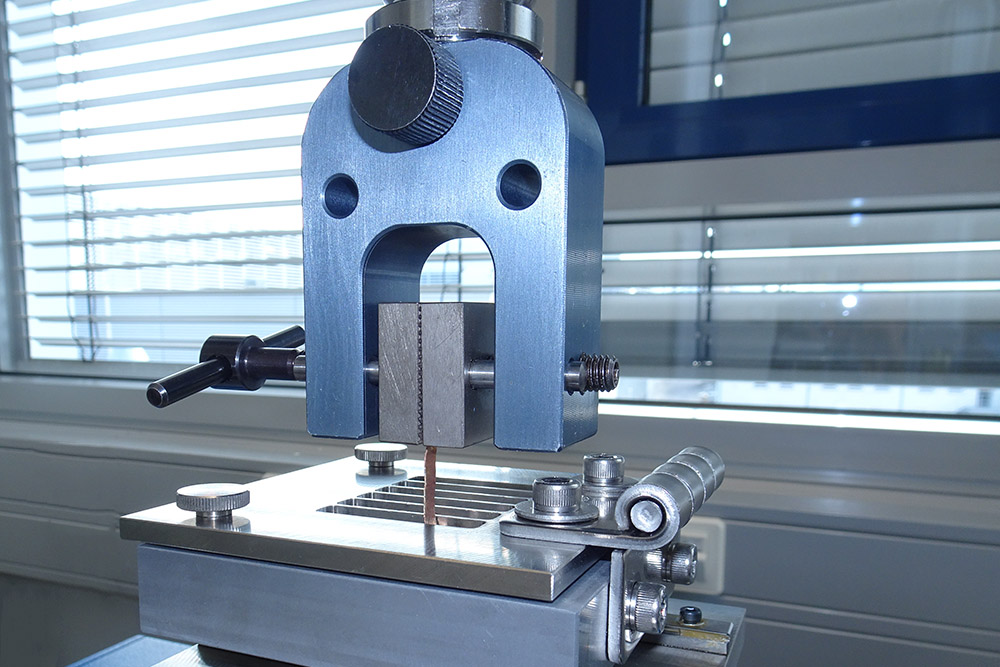

Shear tests

The strength of bonded, sintered, or soldered interconnects is investigated at Fraunhofer IKTS using shear tests. The assembled component is located on a substrate. During the test, a geometrically adapted shear bit is moved against the sample to be tested. After a touch-down, the sample is sheared with a specified shear height, force, and speed. The force-displacement curves are recorded and evaluated.

The quality of the mechanical interconnects is measured on the one hand by the force applied to destroy the joint and on the other hand by the resulting fracture pattern. A special feature at the IKTS is that the staff can test the shear strength for restricted specimen geometries up to a temperature of 600 °C.

This allows the test to be carried out at a very high temperature. Furthermore, investigations in a wide range of applications are possible due to different shear bit geometries and force ranges.

Tensile and peel tests

In the tensile test, material parameters are determined under uniaxial load. Typically, the yield strength, elongation at break, tensile strength and other material data derived from these are recorded. During the measurement, a bar-shaped sample is clamped between the jaws and stretched to break. The stress-strain curves are recorded, and the material parameters calculated from them. The tensile test can also be used to determine the mechanical strength of adhesive, sintered or soldered joints.

A geometric adaptation for substrate support developed in the IKTS group "System Integration and AVT" allows the test to be performed not only under uniaxial load direction, but also under a defined angle (e.g., 90 ° or 180°). This makes peel tests on the mechanical interconnects mentioned possible.