Affordable, green, Neo-PEC – Fraunhofer funds innovative hydrogen technology

Hydrogen plays a key role in the search for future energy sources which reduce CO2 emissions and provide a stable energy supply. Accordingly, the joint project "Neo-PEC" aims to develop a tandem module that will in future produce green hydrogen in a clean and cost-effective manner, thus enabling a decentralized hydrogen supply using an energy carrier which is transportable according to demand. With the help of the module, water is directly split into hydrogen and oxygen by photo-catalytic means (Photo Electro-Catalytic (PEC) Water Splitting). This novel technology does not require expensive electrolyzers and is scalable as required. For the three-year project "Neo-PEC", 3.4 million euros are being made available to the participating partners Fraunhofer IKTS, IST and CSP within the framework of the Fraunhofer internal funding program PREPARE.

Lowering costs and increasing efficiency with innovative module concept

Until now, solar hydrogen has been produced in electrolyzers of photovoltaic systems. Here, water is electrolytically split into hydrogen using solar energy. But such electrolyzers are expensive. Direct photocatalytic water splitting can be operated much more economically because it does not require electrolyzers. In addition, it is more reliable and hardly requires any maintenance due to the low system complexity. However, the current efficiency is just under 1 %: too little to be competitive. The aim of the Fraunhofer research team is to significantly increase efficiency by using new materials, advanced coating processes and a new module concept - this technology would thus be economically superior to PV systems in terms of life-cycle costs and ecological assessment.

New materials and coating procedures for tandem module

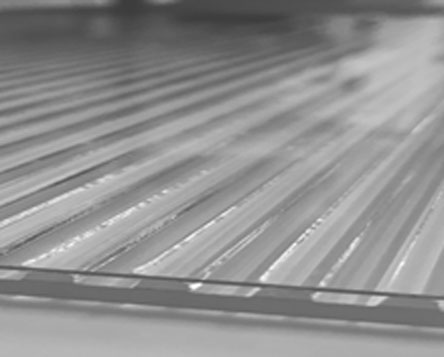

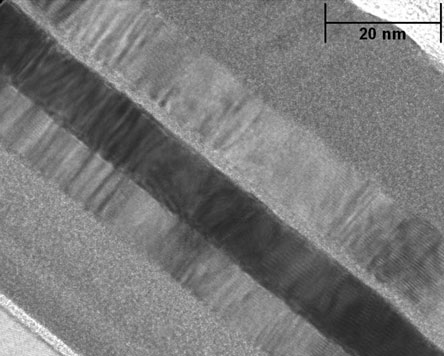

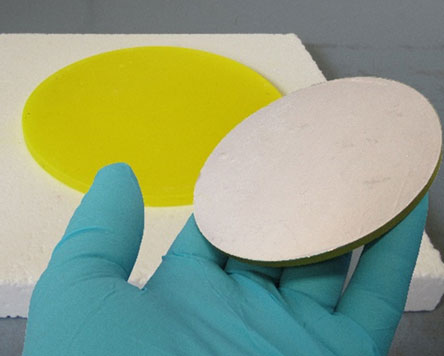

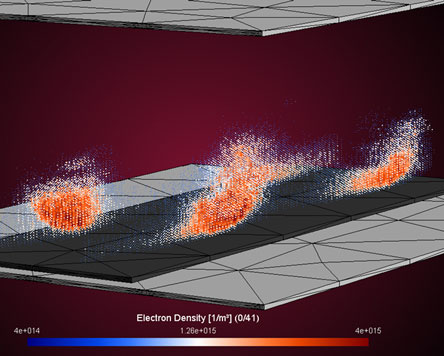

The core of the new development is a tandem PEC module. In a tandem cell, a transparent carrier plate is coated on both sides with different semi-conductive materials. When sunlight hits it, the short-wave light is absorbed on one side (anode). At the same time, the long-wave light penetrates this upper layer and is absorbed on the reverse side (cathode). This releases hydrogen on the cathode side and oxygen on the anode side – a process now being optimized in the project. "To be competitive with conventional hydrogen production technologies, the efficiency of the process must be increased. For this purpose, we are developing new, extremely pure semiconductor materials that are applied using a gentle coating process. This can significantly reduce the previous problem of defect-density in the materials and thus increase the hydrogen yield. This so-called Neo-PEC tandem can be integrated into modules that are freely scalable; it is therefore attractive for the large-scale industrial production of green hydrogen," explains project coordinator Dr. Michael Arnold, research fellow in the Functional Materials department at Fraunhofer IKTS.

PREPARE funding combines the expertise of three Fraunhofer Institutes

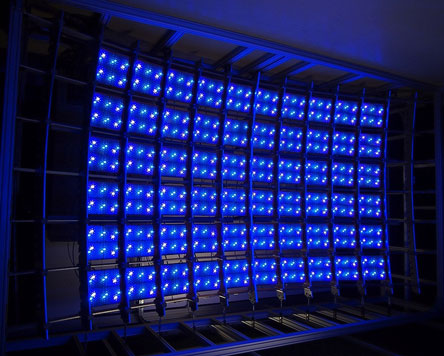

The aim of the joint project is the development of a 1 m² demonstrator. It is designed in such a way that very large areas can be realized using a modular construction - ideal for decentralized hydrogen supply and demand-oriented onward transport. In the project, the coordinating Fraunhofer Institute for Ceramic Technologies and Systems IKTS is researching powder and thick-film materials for the photoactive layer. The Fraunhofer Institute for Surface Engineering and Thin Films IST contributes its experience in cost-effective large-area coating using physical vapor deposition (PVD). The Fraunhofer Center for Silicon Photovoltaics CSP is responsible for the design, production and subsequent evaluation of scalable modules.

Project partners

- Fraunhofer Center for Silicon Photovoltaics CSP

- Fraunhofer Institute for Ceramic Technologies und Systems IKTS

- Fraunhofer Institute for Surface Engineering and Thin Films IST