Laser are well-established and still high innovative coherent sources of photonic energy and are used in many fields of production, sensor technology and communication since 50 years. Beside of higher power and shorter pulses the miniaturization and integration in complex systems plays an important role as another trend in the laser development. State of the art and commercialized examples are laser based projectors for e.g. automobile headlights, LIDAR-systems for local 3D-scanning of car environments or laser sources of different wavelength and power class for bioanalysis.

Multifunctional system platforms based on multilayer ceramic substrates, which are already established in the electronics manufacturing for hybrid, reliable and adjusted electronic assemblies for special working conditions could address the low and middle power range for laser-optical devices. Due to the excellent mechanical and thermomechanical properties of the used multilayer ceramic materials as well as the possibility for 3D structuring and integration of wiring and passive components in the ceramic platforms. The potential multiple panel manufacturing additionally enables the parallel and cost-efficient processing during the platform manufacturing as well as during the hybrid integration of more components.

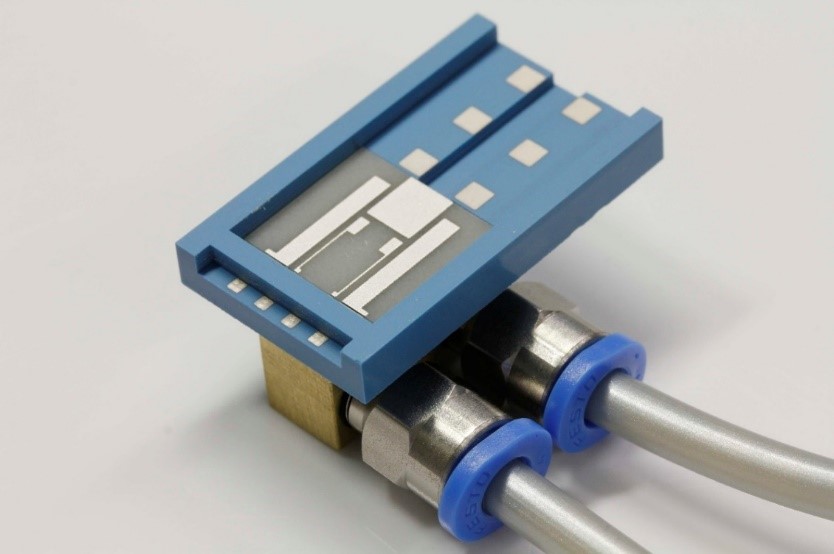

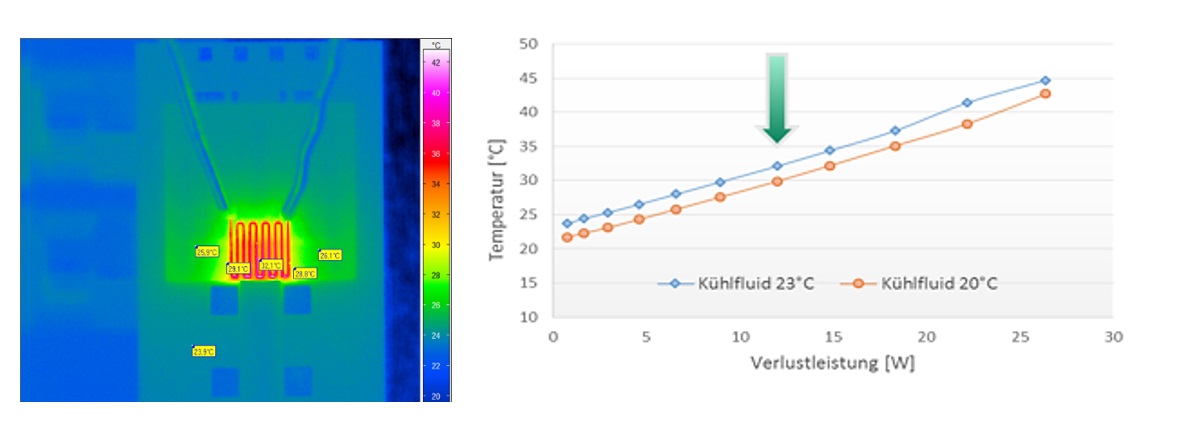

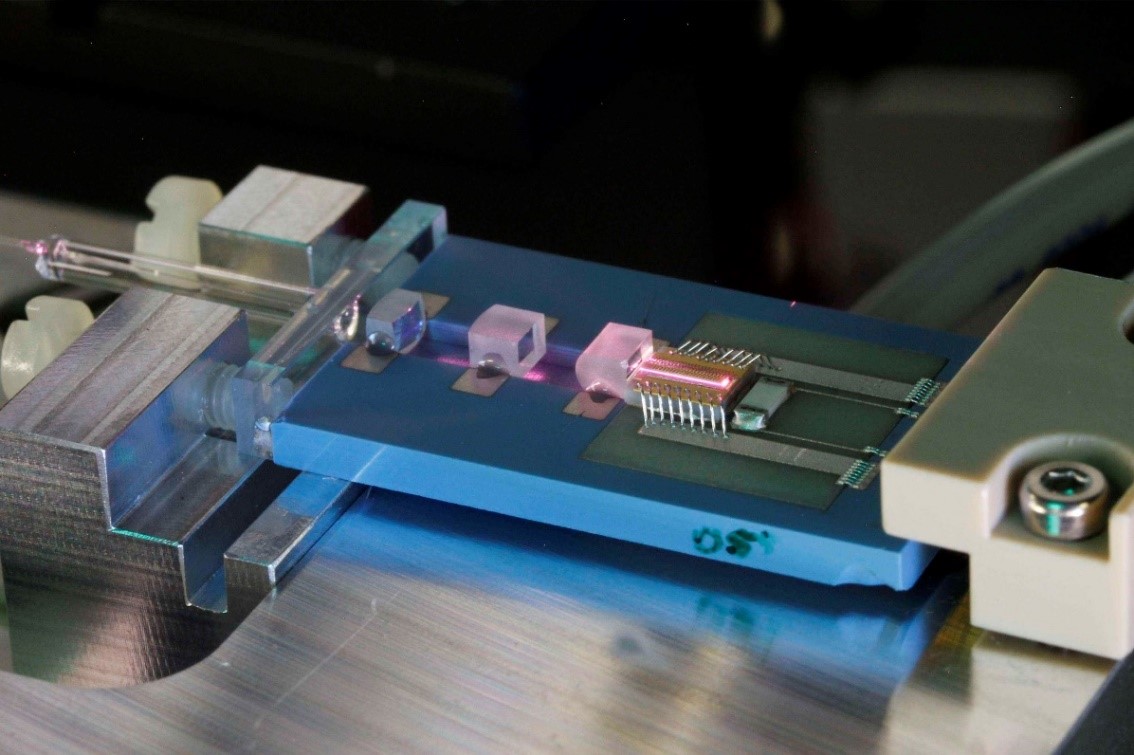

Results of development of the collaboration between Fraunhofer IKTS and IOF is therefore an exemplary multifunctional laser-optical device of high reliability. The use of 3D-structured ceramic platforms with integrated fluidic cooling channels allows the hybrid integration of a laser diode of middle power range (8 W optical, 12 W electrical power) as well as a SMD temperature sensor near to the laser diode for the setup of a closed servo loop for active cooling of the laser diode. Furthermore the ceramic platform includes mechanical structures for the assembly of the beam shaping optics for the fiber coupling of the laser diode and for hermetic sealing of the whole laser device.

In the project cooperation the suitability of the described approach for laser optical devices could successfully be demonstrated. The target markets are laser material processing and sensor technology as well as new markets like structured laser illuminating and laser sources for new processes of communication could be addressed.

Technical data:

- Total size LTCC-Packaging: 30 x 17.5 x 2 mm³

- Size cooling structure: 11.6 x 11.6 mm²

- Manufactured in multiple LTCC panels (8 packages @ 4")

- Power laser diode: 20 W

- Optical power laser diode: 8 W

- Power loss laser diode: 12 W

- Cooling fluid tempered to room temperature

- Thermal resistance of 0.70 K/W for the cooling system @ 23° C coolant temperature

Services offered:

- Customer service concerning manufacturing options in LTCC

- Custom-built design

- Elaboration and qualification of manufacturing processes

- Manufacturing of samples

- Technology transfer