Author: Anika Peucker | Translation: Anna Knollmann

The fake chocolate bar

(Almost) everyone eats them and loves them. It is often described as a small sin for in between and yet it is eaten at any time of the day. Of course we are talking about chocolate. But did you know that...

...chocolate is supposed to reduce the risk of heart attacks?

... the average German eats around 100 bars - 10 kilos - of chocolate a year?

... until the 19th century chocolate was bought in pharmacies because it was considered a strengthening agent?

... chocolate stimulates concentration and memory for a short time after consumption?

... the Fraunhofer IKTS developed a chocolate-coated sensor system?

Yes, you did not misread that. After all, do you know how to measure the different loads in an automated packaging process? With sensors that are introduced into the packaging process and report precisely deviations from the standard. At present, packaging machines cannot yet record such in-line load data. Today, high-speed cameras usually track selected, load-intensive process steps in order to detect irregularities during packaging. This is not optimal. IKTS scientists are therefore researching intelligent, inline-capable sensors that can be used in standardized 4.0 production processes.

The ad-hoc data obtained by the process-integrated sensors are initially used by the researchers to improve machine design. With process-integrated monitoring, engineers can locate the exact area in which a product - the chocolate bar, for example - is damaged and reconfigure these areas. In the future, however, the in-line solution could also optimize maintenance cycles for machines in order to reduce longer and unforeseen machine breakdowns. This would also stabilize the production process, generate planning reliability and reduce the risk of supply shortages.

Miniature sensors in the packaging process

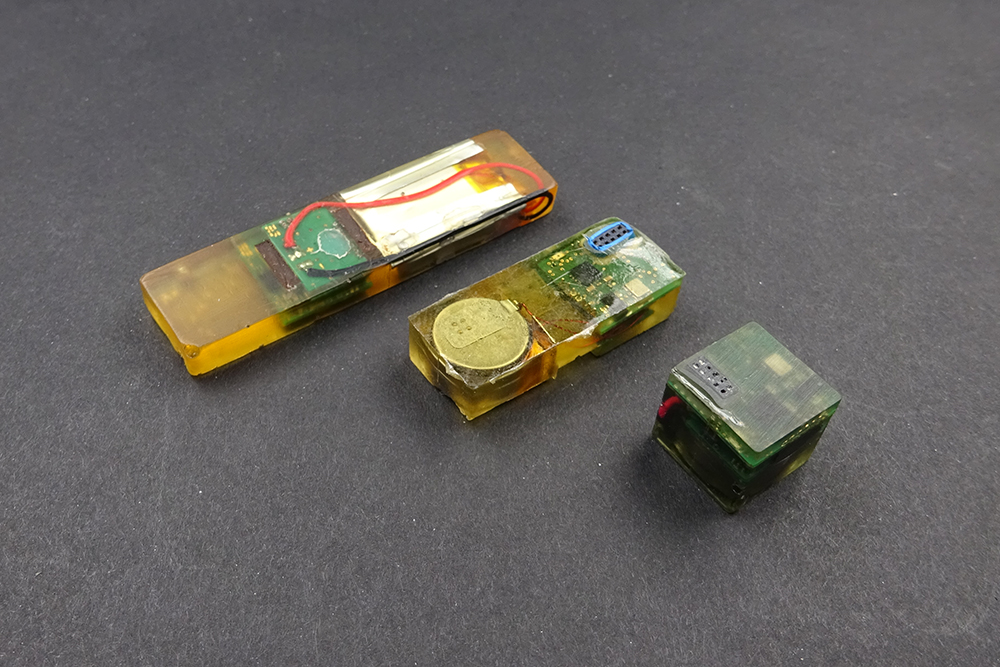

To optimize the packaging process, the Fraunhofer IKTS researchers developed a miniature sensor system. Incidentally, we are talking here about sensor systems measuring 12 x 12 x 12 mm or 12 x 24 x 6 mm for the smallest of their kind. For comparison, a one-cent coin has a diameter of 16.25 mm.

The fake "chocolate bar" contains three different sensors. These detect the fast and slow acceleration rates as well as the rotation rate. The sensors are powered by a rechargeable lithium-ion battery. The data acquisition takes place independently. A Hall sensor was specially installed for this purpose. This sensor starts the data acquisition contactless via an external magnetic field. The data of the sensors is transmitted to a software with which the parameters to be recorded such as sampling rates, measuring range or recording length can be defined in advance. After assembly and wiring, the battery and sensor system are cast in epoxy resin. The epoxy resin serves to protect the sensors from the chocolate with which the compact system is finally coated.

Why does the mini sensor need the "chocolate coating", you might ask yourself now? Well, that has to do with the damping properties of the chocolates. In order to record the exact load and not falsify measurement data, the fake "chocolate bar" must come close to its real counterpart. The chocolate shell absorbs and cushions shocks, similar to the real bar. If the researchers allowed the sensors to pass through the machine as epoxy bodies without a chocolate coating, the measured load would be higher - and thus inaccurate. The epoxy absorbs possible shocks differently than chocolate.

Finally, the chocolate sensor is packaged together with the chocolate bars in the same process cycle. The data is recorded in real time under real conditions and the deviations from the regular process are revealed.

Now you might ask yourself: Is there a danger that I might suddenly bite something hard in my chocolate box? Don't worry. IKTS is currently testing and optimizing the system together with industry partners as part of measurement campaigns. The products from the campaigns do not go on sale. So you can continue to enjoy your chocolate bar without hesitation. During the measurement campaigns, the chocolate sensor is pulled out of the batch at the end of the packaging process by electromagnetic localization.

Miniature sensors: More than just monitoring chocolate packaging

However, the sensors cannot only be used for packaging chocolate. The inline-capable sensor system also offers added value for process monitoring of other food products such as stock cubes, fruit or vegetables. The engineers are also working on reducing the size of the technology. Miniaturization opens up even more areas of application for developing turnkey industry 4.0 solutions for process optimization and developing new business models for maintenance and service together with customers.

Chocolate sensor refines packaging process

Now that you know how to monitor the chocolate packaging process, you may think of the Fraunhofer IKTS next time you select and unwrap your bar. You will remember what a sophisticated packaging process must be behind it to create a moment of pleasure for your eyes and palate. And what challenges do manufacturers and researchers face together to reduce scrap, associated costs and material waste at all process levels.

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.