Authors: Anna Knollmann | Susanne Freund

Printed electronics – what it is and what it has to offer!

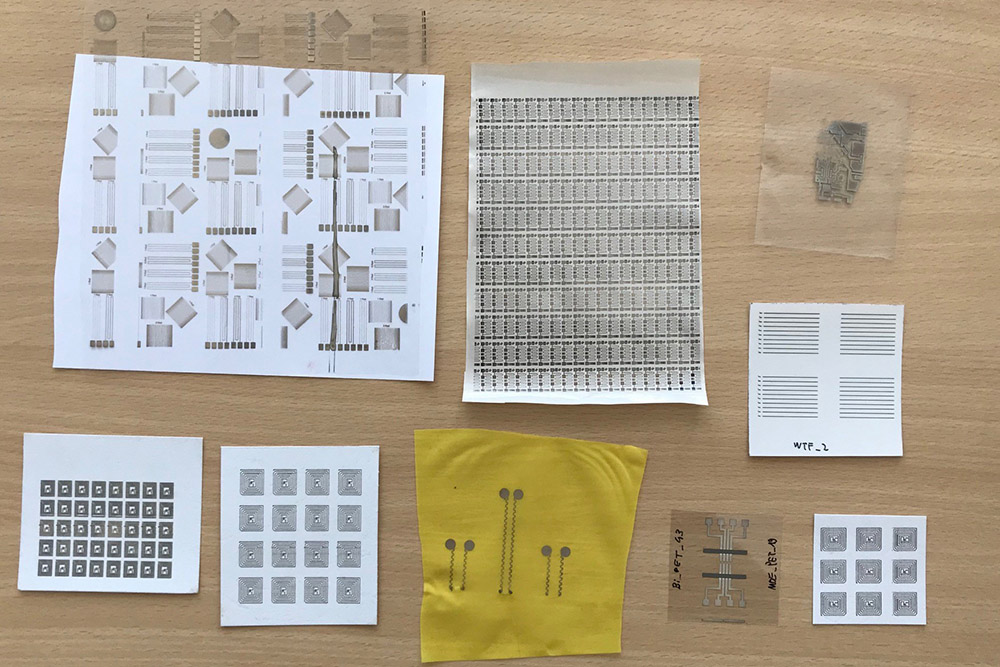

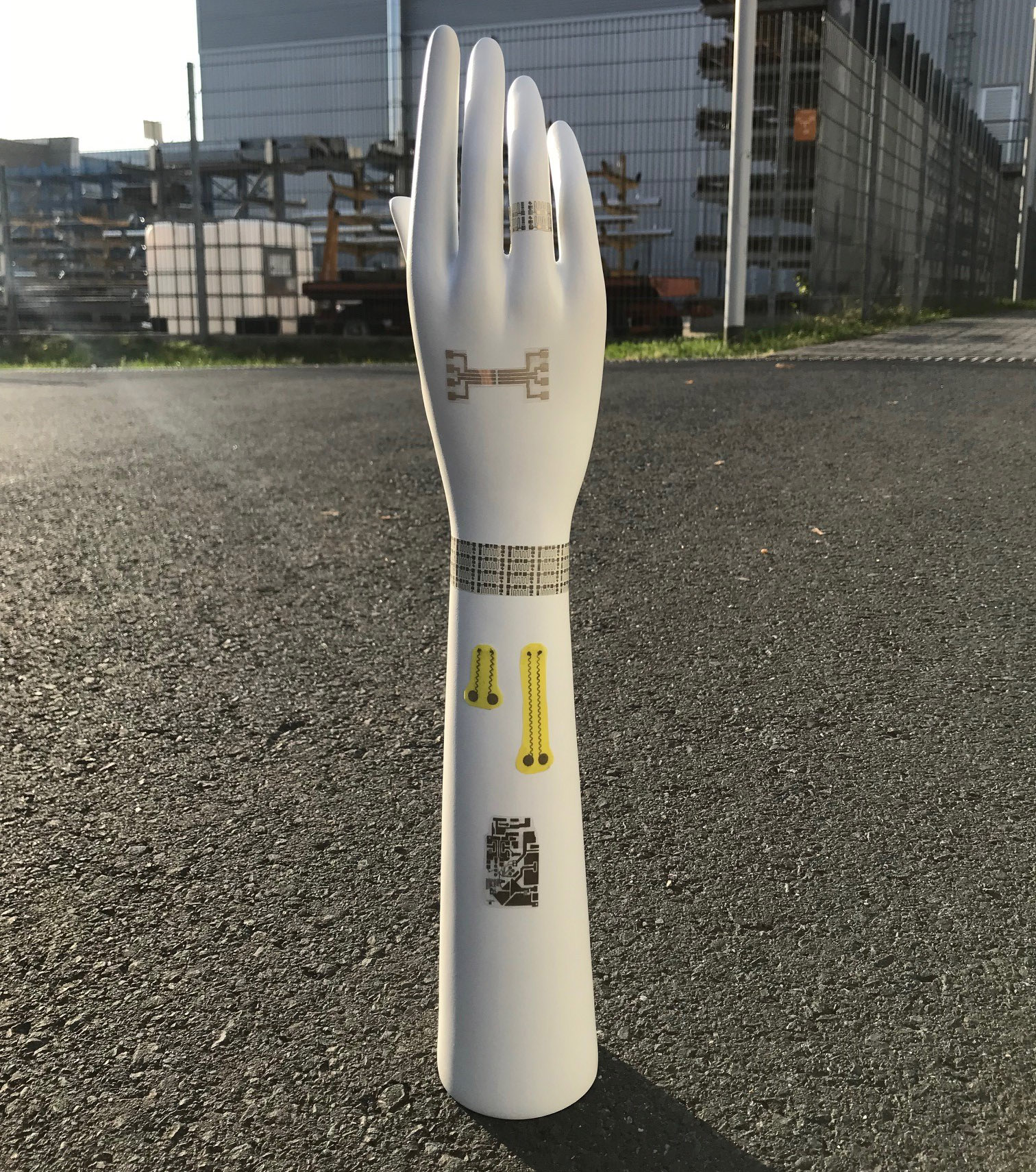

Hi, my name is Anna and I’m a student employee at Fraunhofer IKTS in Dresden. I’m working in the marketing department doing a lot of different things. Last week I got to design a fair exhibit, which will be displayed at the COMPAMED trade fair – which is all about highly-modern medical technologies. My colleagues will be presenting various results of research regarding printed electronics, a branch that is supposed to open new doors in both technical and design possibilities in many branches. A lot of the printed materials, that I got to create the fair exhibit, look extremely interesting and made me curious on what printed electronics are and how they’re used. That’s when I started researching.

What are printed electronics?

According to Wikipedia printed electronics are identified as electronic components, assembly groups and electronic usage that are completely or partly produced through a printing method. Nowadays, there are already a plenty of applications, such as displays for consumer goods or sensors for the automotive industry that use this new technology. The IDTechEx roadmap is predicting a growth of the current market to more than 600 million US dollar until 2027. As an industrial engineer student I’m personally very interested in these numbers and looking for reasons why this technology is so attractive for many different applications.

What advantages do printed electronics offer?

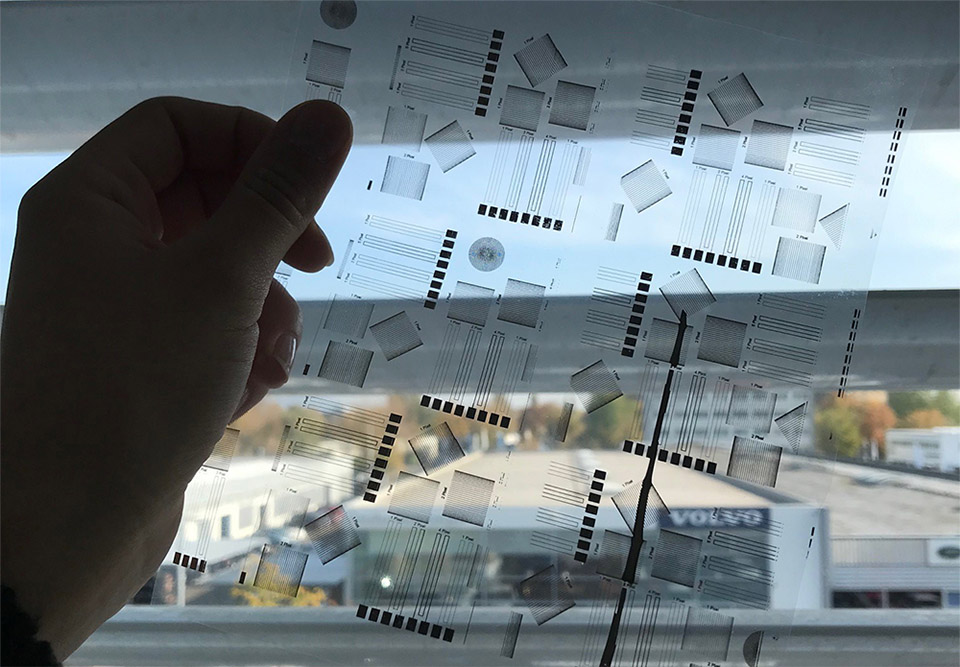

Printed electronics can be extremely thin (less than a millimeter), flexible and widespread shapeable, all advantages that other comparable technologies do not offer. The high resolution printing method is what makes it possible to not only print small structures on flat substrates, but also on 3D structures. All for a very inexpensive price as well. But now I wonder how the medical technology uses this new method?

Where is printed electronics used in the medical technology?

Our medicine develops quickly. Nowadays, for many patients it is quite natural to measure different data on their own at home. An example that probably almost everybody knows is the blood sugar level of diabetics. The goal for the technology is to integrate printed electronics into so called wearables – in clothing or with direct skin contact – so that medical data can be measured and monitored without the assistant of the patient. The ideal case would be for the technology to be working without the patient even noticing. I’ve read that this trend has been developing and growing the branch in the last couple of years. But what is it that the IKTS does in this branch?

Fraunhofer IKTS as a “one-stop shop” for printed electronics

Fraunhofer IKTS offers a 360° service for the development of functional inks and pastes, which are a key element for printed sensors. What this means specifically: we choose the primary products with the matching organic, develop the features that are necessary for the usage – for example conductivity – and adjust the ink or paste to those specific needs. Important parameters at that are viscosity, surface tension, solids content, particle size and temperature. The material spectrum includes gold, silver, platinum, copper and carbon or ceramic based inks and pastes for polymer, textile, paper or ceramic substrates.

Finally, I would like to show you a picture of the finished fair exhibit, which my colleagues will display at the COMPAMED fair next week. If you’re a guest at COMPAMED feel free to come and visit us (Hall 8a/N39)!

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.