Author: Anika Peucker | Translation: Anna Knollmann, Stephanie Anderseck

Organic wax is made from carbon dioxide

Generation Y. I belong to this generation. Some things are imputed to us. A much quoted statement is: We are becoming more environmentally conscious again. In all areas of my life I also try to use natural products and pay attention to the environment.This is particularly important to me in the field of cosmetics, because everyone, including you, uses cosmetics every day. And that is not little: just pause for a moment and think about how many cosmetic products you yourself own and use every day. This is exactly why I prefer natural cosmetics to conventional cosmetics.

But what exactly distinguishes classic from natural cosmetics? Natural cosmetic products contain no synthetic ingredients. This makes the products more compatible and less harmful to the environment. By the way, the market share for natural and near-natural cosmetics in the overall market is not so small. According to Statista, it was already over 16 percent in 2016 - and the trend is rising. More and more manufacturers are also being certified with a wide variety of natural cosmetics quality seals.

When I talked to my colleagues about this topic during my lunch break, they told me that we at the Fraunhofer IKTS are currently trying to produce waxes or alcohols using Fischer-Tropsch synthesis. Such waxes could later be used in the cosmetics industry, for example. I had never heard of this before, but of course I wanted to know more about it.

The Fischer-Tropsch process

The Fischer-Tropsch synthesis is an almost 100 year old process. The synthesis converts different but renewable carbon sources such as coal, natural gas or biomass into a synthetic gas, which reduces the consumption of fossil materials. One potential source of carbon could be biogas plants, for example, because carbon dioxide is produced during the production of biogas. Currently, CO2 is only a by-product or waste product. With the Fischer-Tropsch process, this "waste product" can be processed into wax. The novelty of this process is that it is now possible to produce waxes that are not based on crude oil; animal or natural waxes are of course excluded.

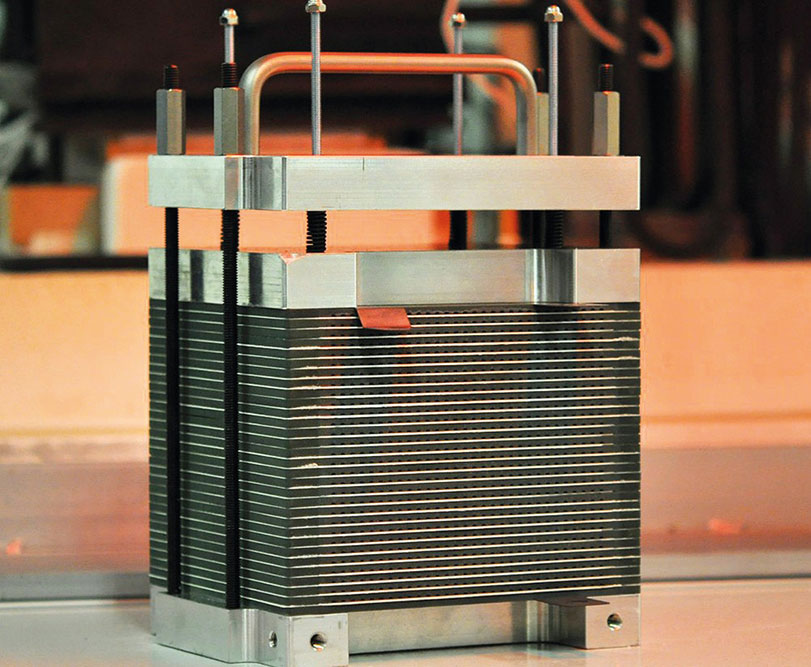

The Fraunhofer IKTS itself is working on Fischer-Tropsch synthesis to make the process more efficient. This involves not only the development of new, better catalysts and catalyst structures, but also their easy replacement. The new catalyst structures consist of a ceramic film technology. This ceramic film technology allows the residence time and temperature gradient to be controlled, thus ensuring the quality of the waxes.

Two new process chains are currently being conceptualized and tested in pilot studies financed by the EU and the state of Saxony. They demonstrate the production of the waxes by Fischer-Tropsch synthesis. The pilot studies are essential to determine the economic efficiency of the process.

What are the advantages of waxes obtained by Fischer-Tropsch synthesis? They differ from conventional waxes such as beeswax, jojoba oil or synthetic waxes such as paraffins in their production.

For example, the "Fischer-Tropsch waxes" are not synthesized as the main product, but casually from a "waste product" - carbon. This promises an optimal use of resources. We waste nothing! In addition, the waxes are particularly suitable for use in cosmetics, as they are free of aromatic compounds. This means that these waxes are better tolerated by allergy sufferers.

"Fischer-Tropsch waxes" - a real alternative?

The fact that waxes produced by the Fischer-Tropsch process will soon be used is still a dream of the future, as the economic efficiency of production has yet to be proven. Nevertheless, the idea of an alternative, environmentally friendly source to petroleumbased waxes is exciting and attractive, especially when considering the further decline in man-made oil reserves.

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.