Author: Fanny Pohontsch

Ceramics to boost the efficiency of solar power towers – How does it work, Alex?

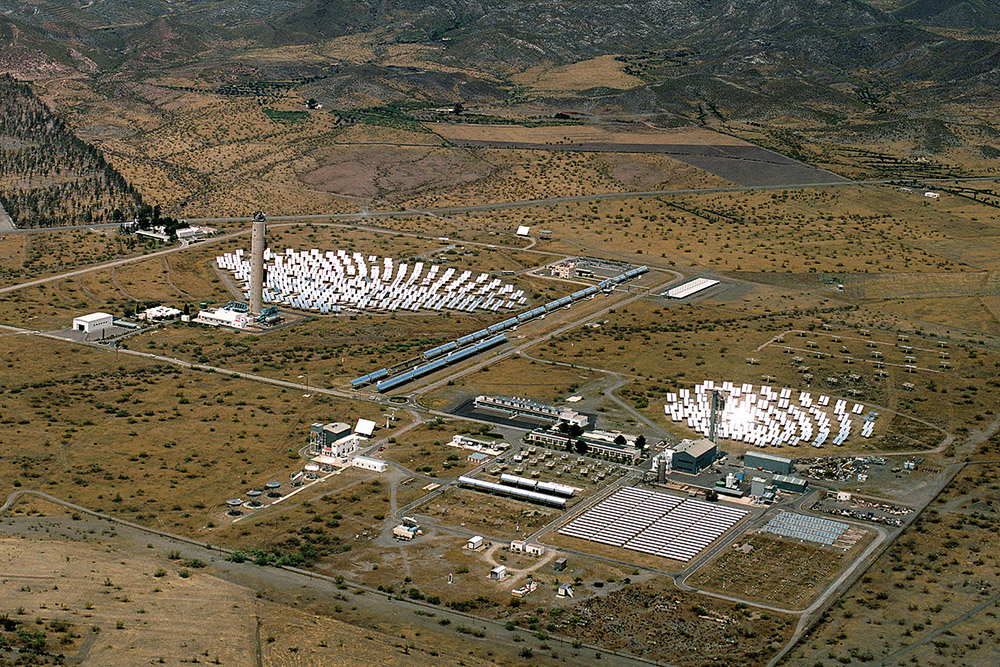

Andalusia. About 60 kilometers from the Mediterranean coast of Spain, in the middle of the Tabernas desert, there is the Plataforma Solar de Almería – the world's largest research center for high-temperature solar technology. The site, on which more than 20,000 square meters of movable mirror surface, so-called heliostat fields, are installed, covers 100 hectares. As part of the EU CAPTure (Competitive Solar Power Towers) project, IKTS researcher Dr. Alexander Füssel develops ceramic components with which the potential of solar tower power plants for the global energy mix is to be better exploited. They are going to be tested in Almería. He explains the solutions the team has found in an interview.

Alex, what makes solar tower power plants so interesting for the electricity market?

Solar energy is by far the largest resource among renewable energies – and solar tower power plants enable particularly high efficiencies. They can thus make an important contribution to independence from fossil fuels. The task now is to reduce electricity production costs.«

So what is the CAPture project’s approach to making this happen?

It is particularly important to achieve higher operating temperatures at the receiver. The receiver must operate at 1000 to 1200 °C, which corresponds to an increase of up to 42 % compared to the current standard. The receiver is the element of the tower power plant that absorbs the sunlight bundled by the heliostats, i.e. the solar mirrors, and emits the heat released into the targeted air flow. An innovative energy conversion process from thermal to electrical energy is also required. An important part of this is an improved control system so that the mirrors of the heliostat field are always optimally aligned with the receiver. In addition to increasing the efficiency of the power plant and its components, we also wanted to find ways of producing these at low cost and ready for mass production as part of CAPture.

CAPture therefore considers solar power plants en bloc – from the design and manufacture of individual components to the controlled system. Ceramics seem predestined for use in this environment!

Exactly! We find ceramics especially in two crucial components: The component with the highest thermal load is the receiver. It requires a particularly resistant material that can absorb the incoming sunlight and heat up without losing too much energy through backscatter losses. The use of ceramics is not new here. However, the pressureless sintered silicon carbide foam ceramic (SSiC) developed at IKTS offers the advantage of better heat transfer from the hot ceramic to the streaming air in comparison to the conventional receiver concept with extruded ceramic honeycombs:

In the irregular foam structure, the air flow is repeatedly divided and merged – in contrast to the continuous channels of a honeycomb. This avoids temperature gradients that carry the risk of local overheating. All in all, the improved heat transfer and the very good thermal shock resistance of the unstructured SSiC foam roughly outweigh the higher manufacturing costs compared to the honeycombs. Another innovative approach for a receiver with rotating ceramic disks was also pursued in the project. However, it turned out that this option is associated with significantly higher manufacturing and operating costs and could not prevail over the existing concepts of honeycombs or foams.

You mentioned a second component?

Yes, in addition to the receiver, a continuous energy conversion is needed. This requires a regenerator which can be loaded with the thermal energy of the hot air from the receiver and unloaded again for the energy conversion in a pressurized turbine circuit. In our case, the structure of the system follows the principle of the so-called Brayton cycle. The design of the regenerator was the responsibility of the Spanish project partner TEKNIKER, with IKTS acting as a consultant to support the design and material selection. A possible solution is extremely cost-effective and resistant cordierite honeycombs with low flow resistance.

What happens next? The project is nearing completion.

After a break due to the current situation, the concluding work is now planned with a final functional test in Spain. The recently completed demonstrator is to be put into operation and extensively tested as soon as possible at the test site of the Plataforma Solar de Almería. This test is intended to show whether the interaction of all the components developed or improved within the framework of the project works and whether it has been possible to increase the efficiency of the overall system and thus make it more competitive. Against the background of these results, an overall evaluation at the end of the project should also provide information on the potential of these types of solar tower power plants as representatives of renewable energy sources.

This project was funded under the Horizon 2020 Research and Innovation Program of the European Union under the Grant Agreement N° 640905.

Further information

- IKTS department »Nonoxide Ceramics«

- Homepage »CAPture-Projekt«

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.