Bio- and Medical Technology

Competences

Ceramic materials and surfaces

- High-purity dense or porous bioceramics [Al2O3, ZrO2 (ATZ, ZTA, Y-TZP), Ca3(PO4)2), HAP, Si3N4]

- Open-cell foam ceramics and metal foams

- Glass and glass ceramics

- Oxide and non-oxide ceramics with precise electric, thermal, mechanical and optical functionalities

- Composites and material compounds (porous/dense, metal/ceramic)

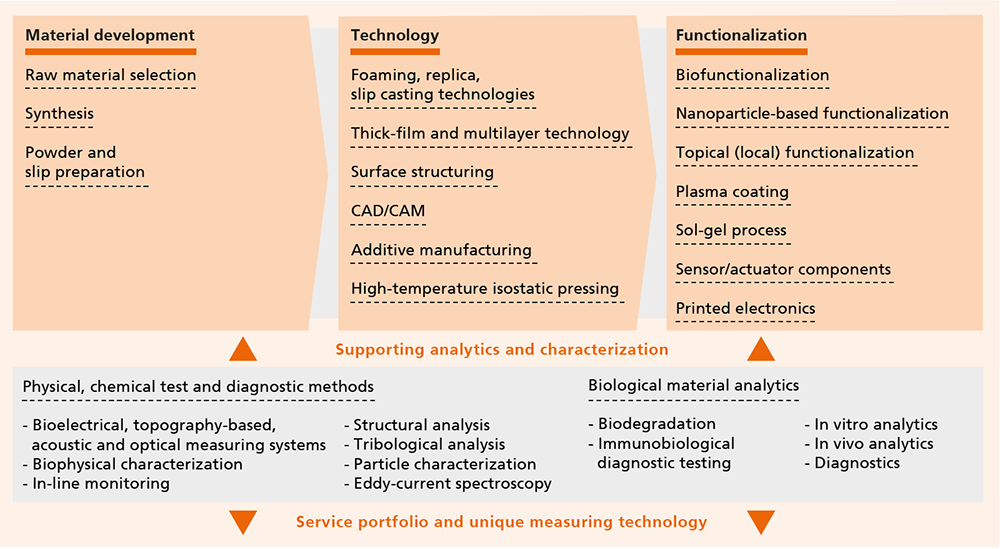

Technologies

- Powder and slip preparation, granulate development

- Casting, pressing and (thermo)plastic shaping processes

- Foaming and replica technologies for cellular structures

- CAD/CAM line, additive manufacturing processes (powder- and suspension-based)

- Manufacturing of blanks and preforms by dry pressing

- Sample series of oxide ceramic semi-finished products (certified according to EN ISO 13485:2016)

- Plasma coating and sol-gel processes

- Thick-film and multilayer technology (complete line for HTCC, LTCC)

- Thin-film technology (thermal CVD, PECVD, thermal ALD, PVD, LPD)

- Joining technologies for ceramic/metal and ceramic/ceramic combinations

- High-temperature isostatic pressing/post-HIP processes

- Micro- and surface preparation; surface functionalization (inkjet and aerosol printing, diode laser array finishing)

- Biocompatible joining and packaging techniques, medical device construction

Diagnostic/therapeutic systems and characterization

- Bioelectrical, topography-based, acoustic and optical measuring systems

- Biophysical characterization on nano, micro and macro level (TEM, SEM, AFM, AFAM, Raman)

- In vivo as well as in vitro analysis and diagnostic systems

- Plasmonic sensor systems

- Biological evaluation of materials (medical products) in accordance with DIN EN ISO 10993

- Differentiation assays

- Development and industrial implementation of innovative in vitro test methods