Author: Maria Kaminski

Thermoelectrics: old effect with big potential for the future

Europe's energy supply is undergoing a fundamental transformation: away from nuclear and fossil fuels and towards renewable energy sources. Especially in the field of energy efficiency, thermoelectrics can offer easily implementable and customizable solutions.

The underlying physics have been known for almost 200 years: Thomas Johann Seebeck discovered that an electric charge can be generated when two temperature levels are present - the so-called "Seebeck Effect". Only a few years later Jean Peltier discovered that this effect can also be reversed. As a result, thermoelectrics can convert thermal energy into electrical energy or use electrical energy for temperature control. Both have great potential for industry and ultimately for the environment.

What sounds so simple, however, poses great challenges for the technical implementation: Despite many years of effort, this energy conversion currently only achieves electrical efficiencies of two to seven percent, depending on the temperature difference, temperature range, the material used and system integration. Consequently, thermoelectrics have so far only been used for niche applications. This is precisely what the project “Sächsisches Forschungscluster – Thermoelektrik in industriellen Anwendungen” (Saxon Research Cluster - Thermoelectrics in Industrial Applications, short: TE-VorClust) aims to change.

Will thermoelectrics prevail as a future technology and find a broader application in industry?

We asked our expert in thermoelectrics Dr. Hans-Peter Martin about this.

What does the TE-VorClust project stand for?

Today, thermoelectric applications are on the rise: As Peltier elements or thermocouples, they have already proven themselves for cooling and thermal management or as temperature sensors in various applications. However, there is also great potential in heat generation using thermoelectric materials, modules and generators, which has been the subject of increased research for several years. Despite these many efforts, so far only relatively low efficiencies have been achieved using this energy conversion. In addition, for many technicians and engineers thermoelectrics often still represents an exotic physical phenomenon. Therefore, it is our goal to establish a project network of science and industry in the field of thermoelectrics in order to develop applications that meet the needs of the market. After all, thermoelectric effects have great potential for attractive innovations in technical devices or in everyday life - with the aim of saving resources, designing more environmentally friendly processes or advancing Industry 4.0.

What specific contribution does IKTS bring to the project?

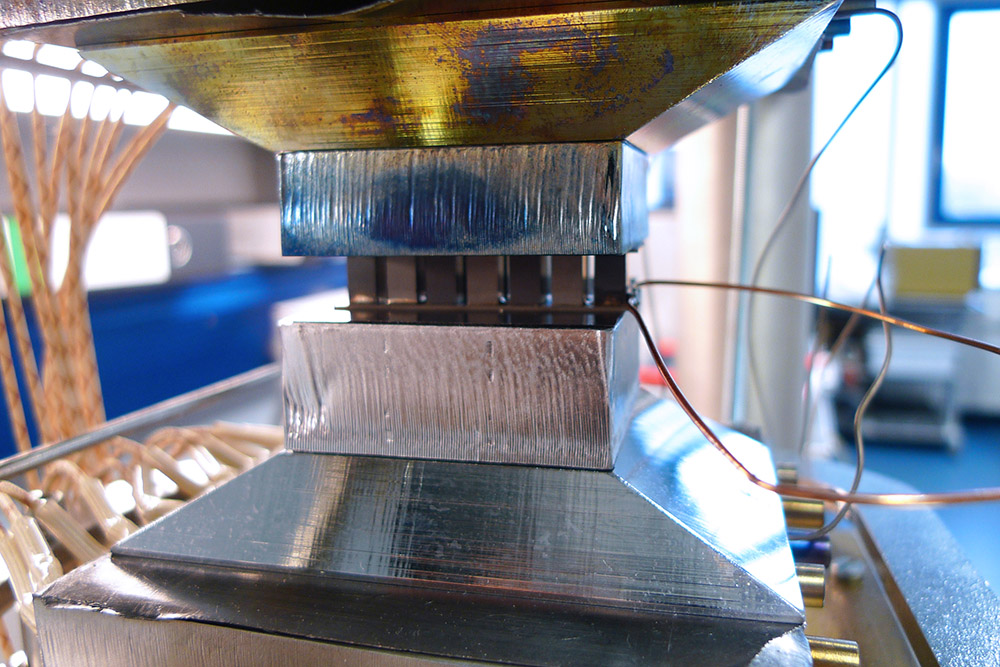

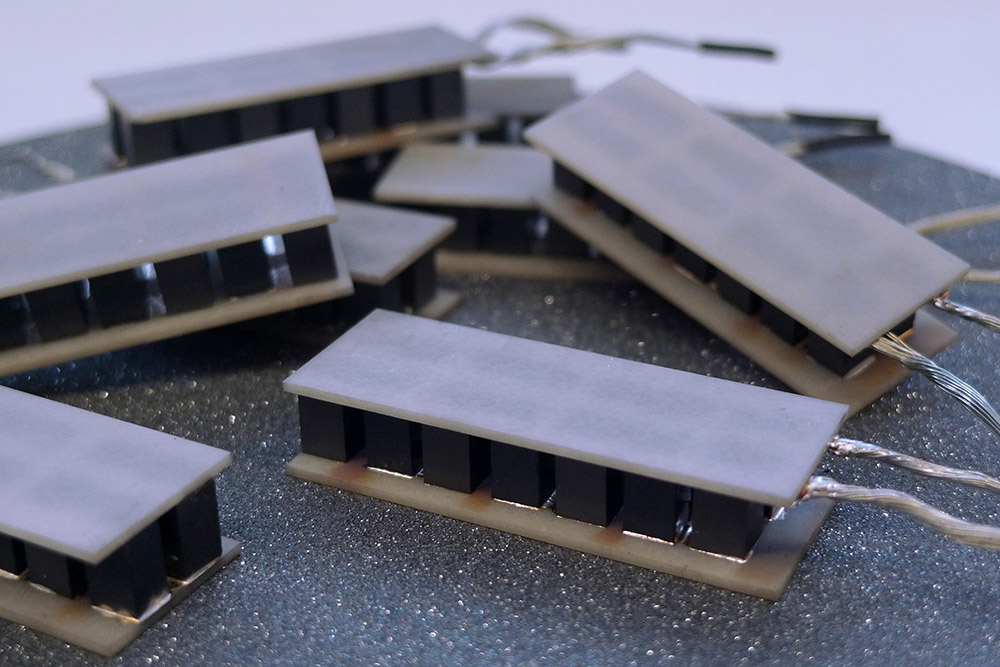

Fraunhofer IKTS has been conducting extensive development work in the field of ceramic thermoelectrics for more than ten years. For example, we are working on materials development and the establishment of electrical connections for thermoelectric components. In these activities we benefit greatly from our many years of experience in the fields of fuel cell, sensor and thick-film paste development. In addition, IKTS also has working groups that deal specifically with system integration, the simulation of operating conditions or material-specific ageing behavior, which is also of great interest for thermoelectric developments. In cooperation with our project partners, Technische Universität Dresden, Max Planck Institute for Chemical Physics of Solids, Leibniz Institute for Solid State and Materials Research Dresden, Fraunhofer IFAM Dresden and Fraunhofer IWS, this results in a Germany-wide or perhaps even Europe-wide unique clustering of competences and capacities in this field, which promotes new developments.

Which market sectors are receptive to innovative thermoelectric components?

This is a question that is to be answered ultimately with the project result. So far, numerous ideas for potential market sectors have been collected, among others in the fields of building services engineering, temperature control technology, self-sufficient sensor networks and various manufacturing technologies for Industry 4.0.

Could you give us an example to illustrate this?

Let's take a look at the building services engineering sector. Here the requirements have changed significantly over the last ten years: The demand-oriented air conditioning of work and recreation rooms in companies or residential buildings is increasingly in focus. At the same time, however, energy consumption is to be steadily reduced and maintenance requirements minimized. Here it is conceivable to integrate components that use the Peltier effect for temperature control as self-regulating cooling/heating combinations. In order to implement this idea in the best possible way, however, the requirements of architects, engineers, materials scientists or electrical engineers must also be integrated. This requires specialist knowledge. It is therefore all the more important to bring together precisely these experts so that such components can be developed and integrated as required. In addition, temperature control technology based on Peltier technology can use entire surfaces for air conditioning to significantly increase energy efficiency. Thermoelectric temperature control is practically noiseless and is therefore particularly convenient.

What technological steps are required to make these ideas work?

The big challenge is to optimize the manufacturing costs of thermoelectric products, but also to advance their integration into existing systems. For the latter, cooperation between various specialists from science and industry is particularly necessary in order to change the design of thermoelectric components. Thus, they can be better integrated into already existing and newly developed systems. Thermoelectrics is always an energy conversion, whereby the efficiency of this conversion is more or less interesting for the application. A sensor converts almost no energy, so the efficiency is not of interest here. For cooling processes or for the production of electrical energy, the efficiency sometimes even plays the most important role. The overall efficiency of the system is decisive, which is why thermoelectrics can also be attractive – thermoelectric energy conversion is a very simple overall process.

What are the next steps?

It is expected that a further workshop will be held in December 2020 as part of the project. I am looking forward to many exciting, advanced and new project concepts that are currently being developed and can certainly be expanded in the coming months. The contributions of the participating companies in particular will certainly draw attention to further application options. When the companies and institutes come together in project groups, the most important goal of the project will be achieved.

What is your vision - How will thermoelectrics develop in the next ten years - what are your hopes?

In the field of thermoelectrics, I would like to see significantly more components with thermoelectric function in use in ten years' time. This would allow new technical options to be developed, especially for self-sufficient energy sources, which play an important role in the realization of Industry 4.0. I can also imagine that the performance of sensors will be improved by means of thermoelectric effects. Perhaps there will then be high-temperature thermocouples made of boron carbide, which are currently being developed at IKTS, as standardized temperature sensors on the market. Finally, thermoelectrics could also be used to achieve significant energy savings in the air-conditioning of homes, offices, factory buildings or vehicles. In my view, it would be perfect if our current research activities were then also reflected in the economic activities of companies in the region.

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.