Author: Andrea Gaal

Battery manufacturing – where can we improve?

Surely you too have asked yourself whether batteries for e-mobility are really safe; especially when they are in your own car. In order to perform quality assurance faster and more efficiently in the future, we are developing x-ray and thermography systems with which individual battery components can already be inspected during production.

With battery cells, a technology is integrated in vehicles that consists of many layers of very thin functional elements. These are exposed to a wide variety of stresses from our environment and infrastructure – including impacts, vibrations, moisture or temperature changes. To ensure that the battery functions reliably, production-related damage to the functional elements must be ruled out. The prerequisite for this is that testing is carried out at various points in the manufacturing process.

Manufacturing of battery components

A battery is composed of several layers of battery cells. Each battery cell consists of an anode, a cathode and a separating layer, or separator. The basic materials for the individual layers are processed into pastes and applied to carrier films. These are then rolled and dried before being assembled into stacks, the battery cells.

Testing already during production

Until now, battery cells have mainly been tested at the end of the manufacturing process. This means that the finished battery is tested for leak tightness and electrical performance.

Since the production of battery components is quite resource- and energy-intensive, it is worthwhile to test as early as possible in the manufacturing process. This allows defective parts to be found and sorted out before further processing.

That is where we come in: our idea is to check the individual parts of the battery – especially the battery foils – for defects during production. With non-destructive component testing, essentially all manufactured components in a series can be inspected – not just random samples. This increases product safety.

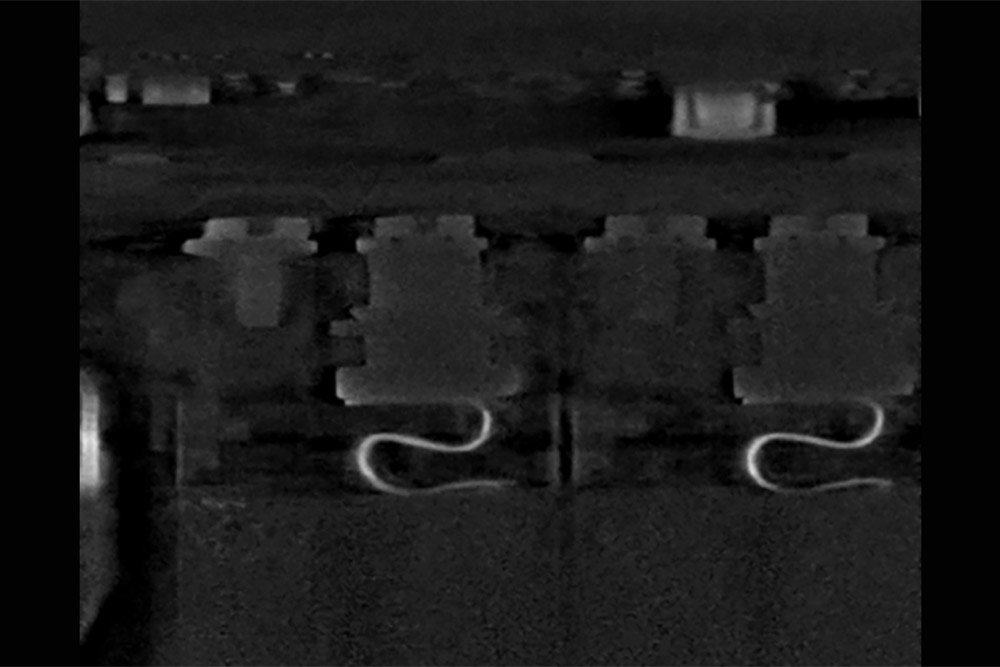

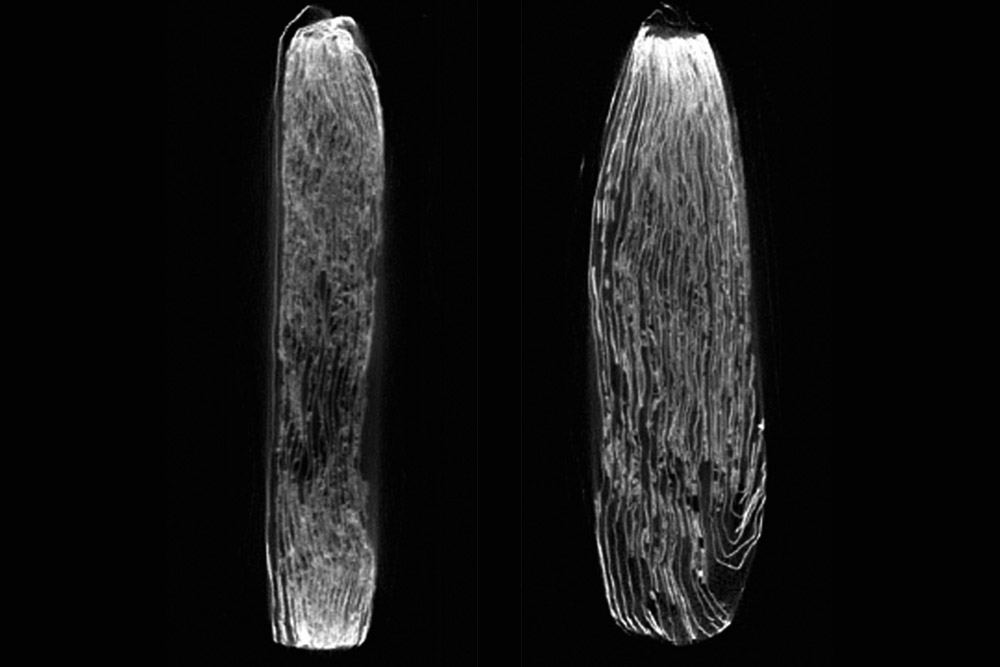

X-ray and thermographic methods inspect non-destructively

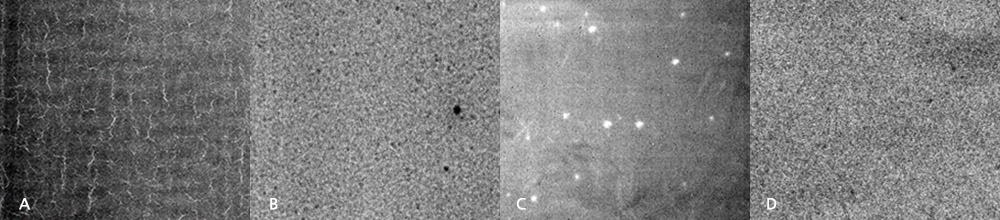

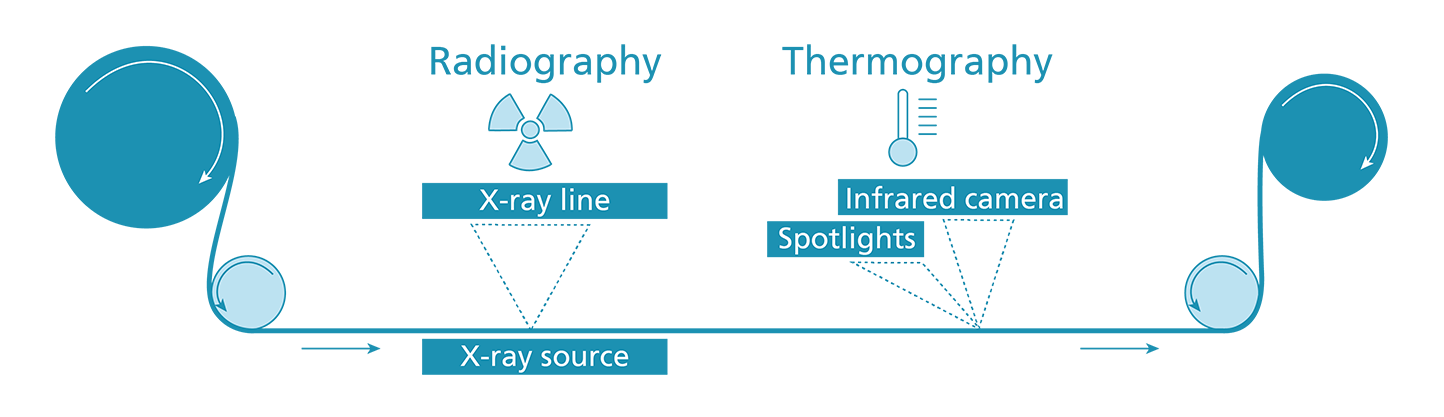

X-ray technology and thermography work very quickly, without contact, and can be integrated into the manufacturing process of battery foils with relative ease. Initial tests show that both methods have the potential to reliably detect a wide range of defects and inhomogeneities. We are currently investigating which defects can be detected in each case and in which quality, and what conclusions are relevant for the evaluation of the process.

Although both methods work very similarly and deliver similar imaging results, they detect different defects (see images). However, it is becoming apparent that the results of each procedure are not sufficiently meaningful on their own. Here, an overlay of the images (data fusion) from both methods will provide further insights.

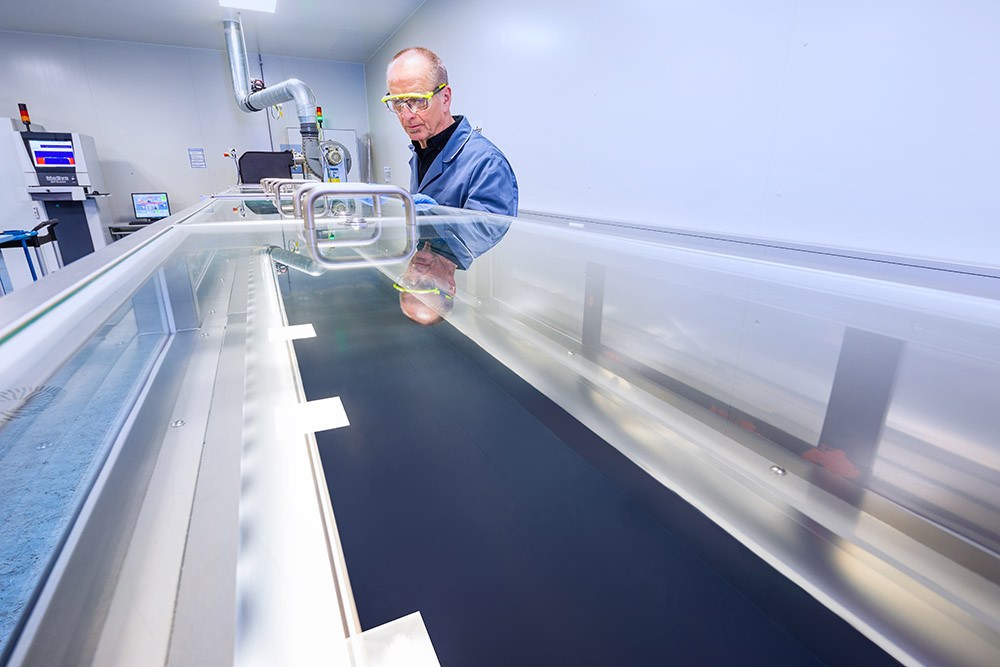

Concepts for integration into the drying channel

Our project team is currently working intensively on optimizing both methods for the testing of battery foils, qualifying them for inline testing and developing evaluation algorithms. The first prototypes of the measuring stations are being built and are already available. In addition to extensive measurements and evaluations, the demonstrators are also available to external interested parties.

Further applications of x-ray technology

In addition to inspecting battery foils in the manufacturing process, x-ray tomography is suitable for other interesting applications. For example, it can be used to non-destructively inspect batteries that have already been assembled from their individual components. During this final inspection, it can be determined whether all individual parts are free of defects and have been correctly connected.

Even when the battery eventually has to be replaced, x-ray tomography can be used. A so-called post-mortem analysis provides important insights into the battery's aging and defect behavior. These results can then be used to optimize the materials and components used.

Further information

- Group "Cell and Process Development"

- Testing of filling and wetting processes in battery cell production [PDF 1 MB]

- Fraunhofer Technology Center High Performance Materials THM

- Battery Innovation and Technology Center BITC

Stay informed:

You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.