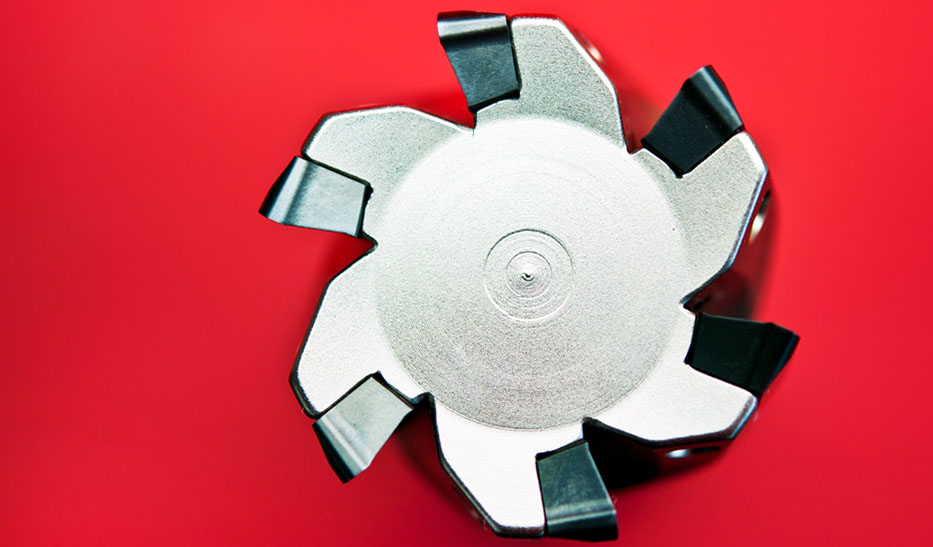

Hard coatings for cutting tools: German-Czech research project started

Within the framework of the EU joint project “MiDiCoat“, coating systems made of titanium carbon nitride and aluminum oxide are to be further developed over the next three years in such a way that they can be used for tools in the high-speed machining of metals for longer periods of time without the use of lubricants that are hazardous to the environment and health. In addition to the Fraunhofer IKTS in Dresden, the TU Freiberg and the Czech tool manufacturer and supplier Dormer Pramet are involved.

Cutting tools have so far been coated with a layer of titanium carbonitride (Ti(C,N)) and optionally a layer of aluminium oxide (A2O3) in the form of corundum. In industrial practice, however, the drill bits coated in this way can only be used for a limited period of time, as the adhesion between the two layers diminishes over time. Cracks appear in the surface of the corundum top layer and it flakes off, the drill tips corrode and have to be renewed.

Thin hard coatings by CVD

“The coating systems are applied by chemical vapour deposition (CVD). Our task is to develop the fundamentals for improving adhesion problems between Ti(C,N) and α-Al2O3 layers and for avoiding surface cracks in the α-Al2O3 layer by means of targeted process variation,“ explains Dr. Mandy Höhn, project manager at IKTS. To this end, her team is experimentally testing the possible parameters for interface design before they are subsequently analyzed microstructurally in Freiberg. In Šumperk in the Czech Republic, Dormer Pramet is testing the new hardmaterial coatings for their suitability for practical use in the production of cutting and machining tools. “The possible increase in tool life and cutting speeds not only allows productivity to be strengthened, it also helps to save raw materials and minimize recycling costs“.

Funding

The project “Microstructure Design of Innovative Interfaces of CVD Hard Coatings (MiDiCoat)“, funded with a total of one million euros, is part of the M-era.Net network. M-era.NET is financed by the European Union, which has been supporting and coordinating European research and innovation programs – especially in the field of materials science and materials technology – since 2012. The consortium M-era.Net contributes to the ongoing restructuring of the European Research Area (ERA). It promotes scientific excellence and the transfer of the results of basic research into practice as a basis for industrial innovation. M-era.Net strives to develop long-term cooperation between research-funding organizations in individual regions, in Europe and worldwide.

Supported by