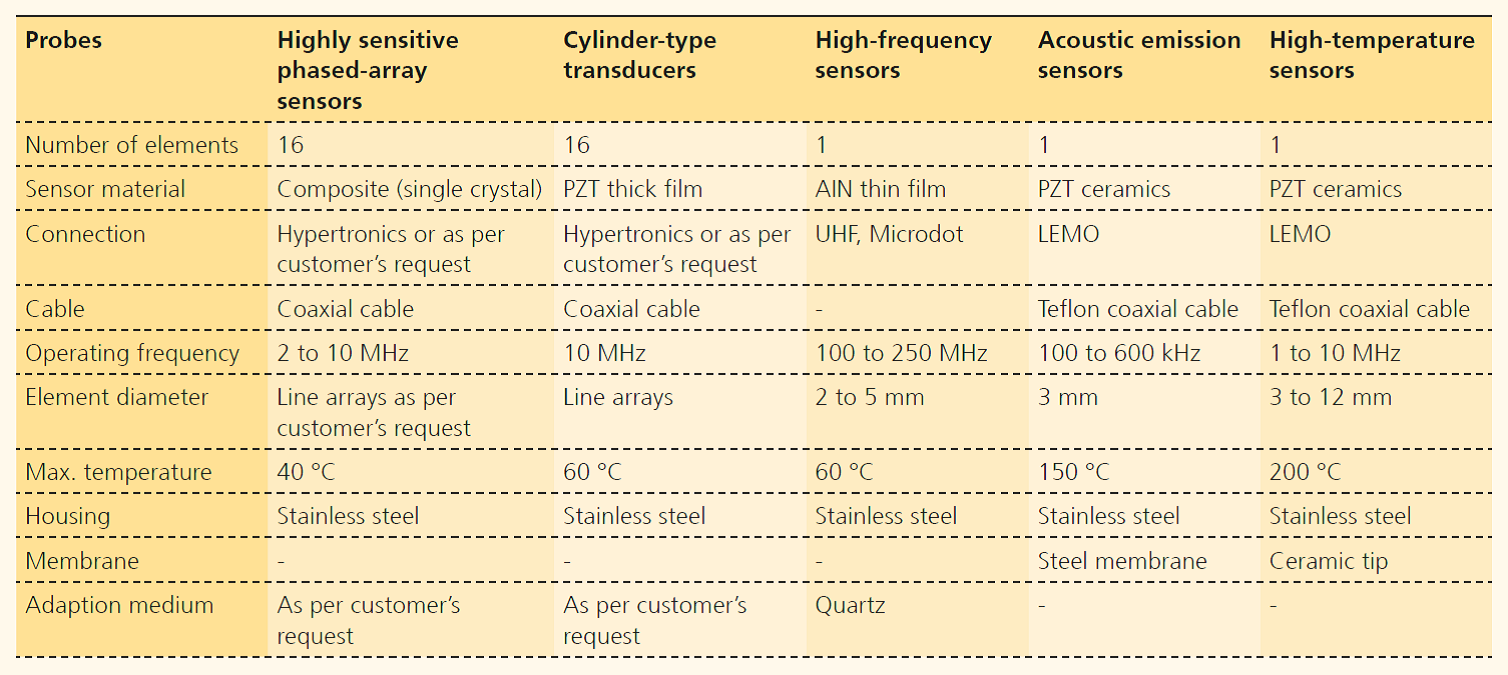

Ultrasonic probes and sensors

Ultrasonic probes are used in many branches of industry for non-destructive testing (NDT) of materials. With various frequencies, configurations, connector styles, and cable types ultrasonic probes of IKTS detect the precise location of objects for a safe and reliable assessment of defects.

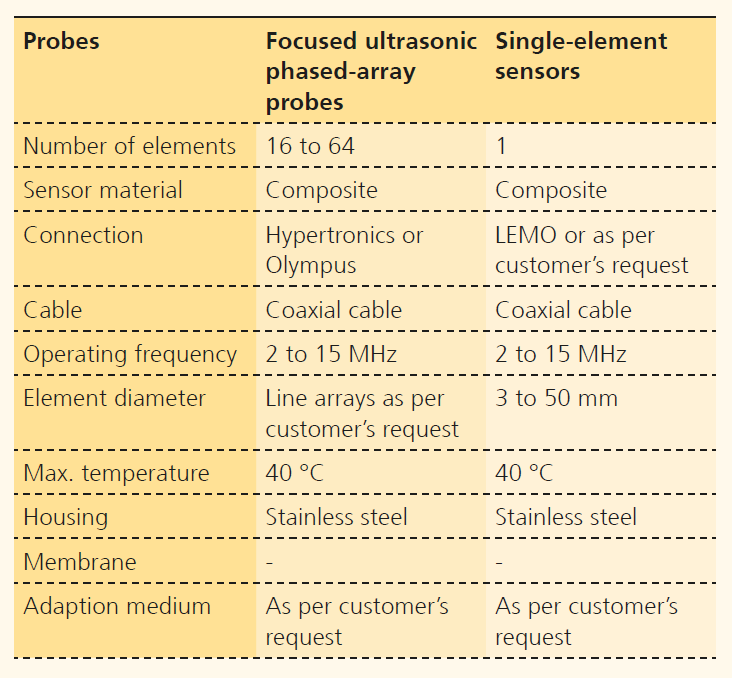

Focused ultrasonic phased-array probes

Fraunhofer IKTS supplies special probes for ultrasonic applications at curved construction components, pipes and holes. The focused/curved ultrasonic phased-array probe focuses the sound field geometrically, improving the sound transmission into the test object.

Single-element sensors

The measurement with a single element sensor, combined with the analysis of the travel time between two successive wall echoes, enables great precision without systematic errors. Fraunhofer IKTS supplies single-element sensors for immersion technology, for instance with a water tightness of up to 2 m water column and up to 9 m cable length.

Highly sensitive phased-array sensors

Fraunhofer IKTS supplies highly sensitive sensors for ultrasound test applications of spot welding seams, in strongly anisotropic materials, especially in the automotive industry. 6The sensitivity is more than 10 dB higher than in sensors based on piezo-ceramic polymer composites. Moreover the relative bandwidth increases by 20 percent.

Cylinder-type transducers

Fraunhofer IKTS supplies special transducers manufactured by the tubular printing of thick-film piezoceramic pastes onto cylindrical substrates for inspection tasks in ducts of heat exchangers, hollow shafts and smaller tubes. These can be designed as phased arrays or as line-focused transducer. This opens up new potential for the ultrasonic testing of small inner diameters within the sample (10 to 30 mm).

High-frequency sensors

Fraunhofer IKTS manufactures sensors based on an aluminum-nitride thin-film transducer with a frequency range of 100 to 250 MHz. These high-frequency sensors are used for ultrasonic microscopy as a focusing or non-focusing version.

Acoustic emission sensors

Acoustic emission sensors are available for the active and passive structural monitoring of steel pipes, vapor pipes and large tank bottoms, depending on costumer´s request and the required temperature stability in the typical frequency range of 100 to 700 kHz.

High-temperature sensors

Fraunhofer IKTS supplies suitable specialist sensors for measuring construction components, liquid media and samples from steel, nonferrous metals, aluminum with alloys, plastics, ceramics and glass. The sensors can be used for the most varied applications in temperatures of up to 200 °C. They are designed and manufactured for testing in contact method or immersion technique.