Development and testing of sensor-based stirring systems in biogas plants to increase efficiency and process stability in load-flexible and demand-oriented biogas production

Due to the storage capability of biomass in combination with a load-flexible operation of the plants, power generation in biogas plants can be operated according to demand with very short lead times. Due to the constantly changing load profile of feeding, gas production and power generation, a comprehensive flexibilization of biogas production places high demands on the central and peripheral plant technology as well as on the stability of the existing process biology. In particular, the fluid dynamic processes taking place in the fermenter are the focus of attention since they have a significant influence on the real biogas yield.

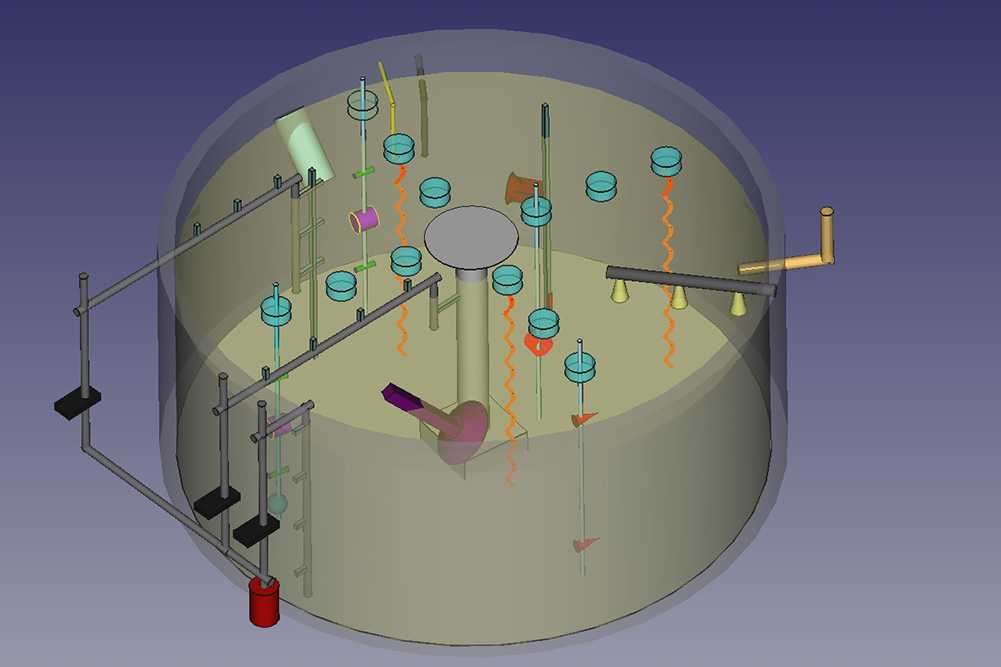

To meet the high demands associated with highly flexible biogas production, the agitation systems, substrate treatment technologies and digestate/process water management must be included in the process optimization. As part of the BMEL/FNR joint project OptiFlex (FNR, FKZ 22401617), the model-based predictive feeding control has already been coupled with a control algorithm to be set up for the agitator and peripheral plant technology, and the corresponding I&C technology has been developed. Using process tomography and numerical flow simulation, it was possible to derive optimum operation of the stirring technology for selected substrate mixtures and to draw specific conclusions about the necessary substrate pretreatment.

Automated process control for flexible biogas production requires comprehensive recording of relevant measured variables in real-time operation, but this is not known in this form. In particular, automation of the mixing processes requires spatially resolved online measurement of the fluid dynamic and biochemical processes taking place in the fermenter. The aim of the Fraunhofer IKTS subproject is to develop an AI-based control system that can be used to ensure permanent, safe operation of biogas plants when using challenging substrate mixtures and load-flexible operation.