Efficient and wear-resistant stirrers for biogas plants

Current research

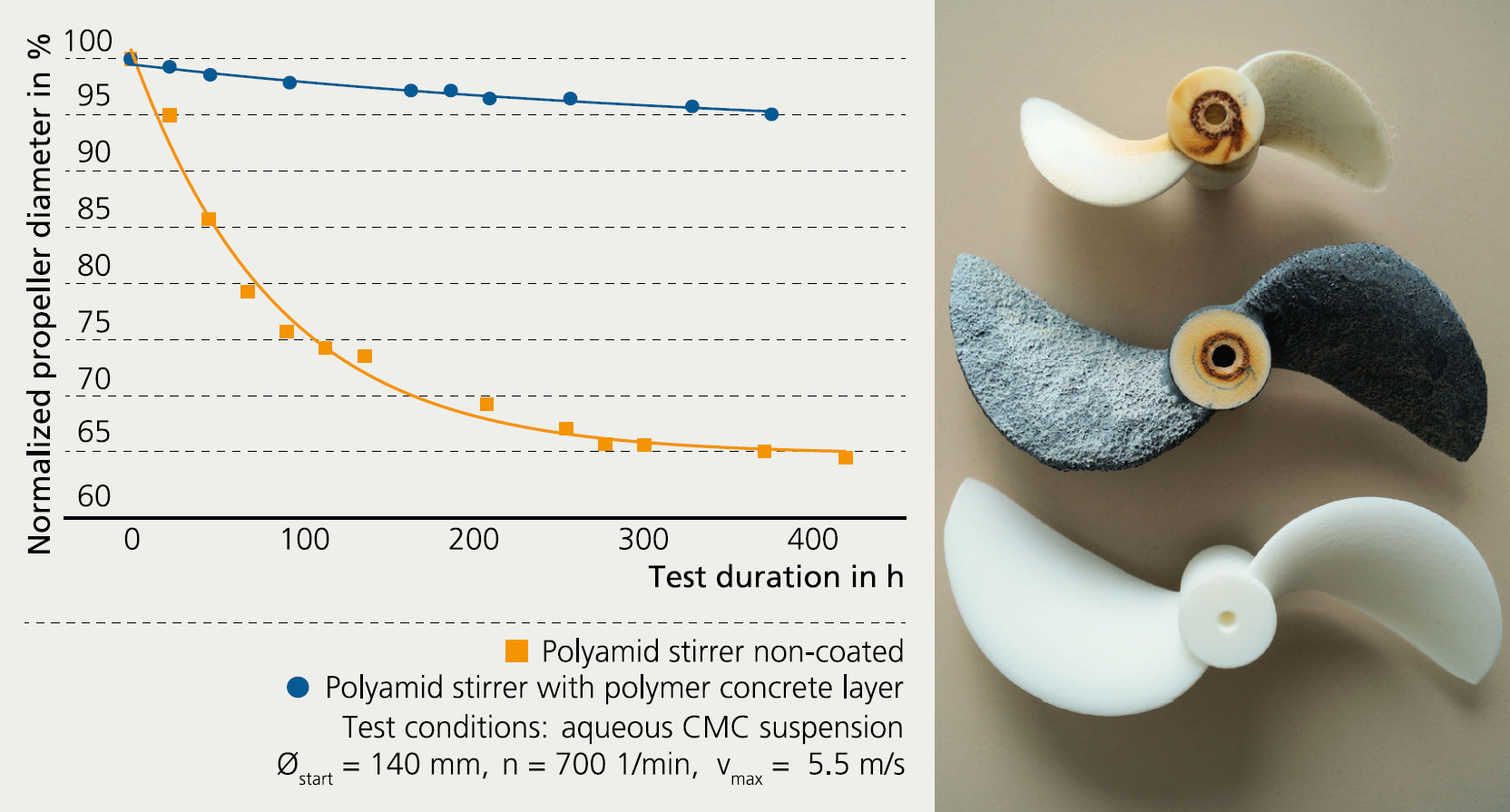

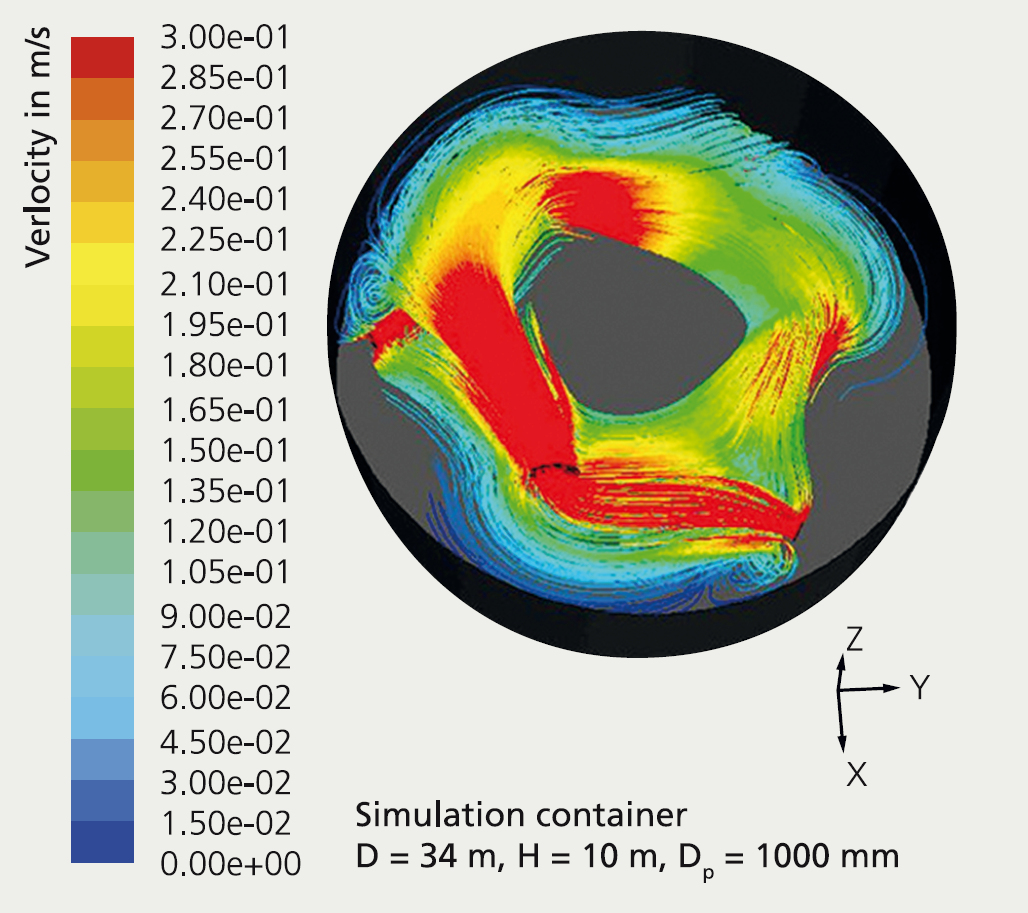

The main functions of stirring devices installed in biogas plants are to mix fresh substrate with the digestate, to reduce temperature gradients in order to achieve stable environmental conditions, and to avoid floating layers as a prerequisite for the free release of biogas from the suspension. Due to the high tribological and corrosive stresses caused by the aggressive digestate, the service life of stirrers currently in use is very short. Fraunhofer IKTS is working with the stirrer manufacturer RTO GmbH and the mineral casting specialist SiCcast GmbH to find better solutions. Changes in the design of the stirrer geometry and with regard to mineral coatings are being investigated, with the goal of developing a new stirrer generation with increased efficiency and wear resistance. The researchers have developed a special stirrer design with improved mixing efficiency based on CFD simulations. The mixing performance achieved by the optimized stirrer geometries was validated through electrical resistance tomography (ERT) measurements. To extend service life, polymer concretes were used as wear protection layers in the tribologically stressed zones of the stirrer. Investigations at the wear test stand for stirrers of Fraunhofer IKTS showed that the silicon carbide coating developed leads to a significant reduction of wear compared with the standard material. The results of the tribological tests are shown next to the diagram (stirrer at bottom: initial state, center: after wear coated, top: after wear non-coated). The exposure to digestate confirmed the suitability of the polymer concrete coating for this field of application. A pilot test in a biogas plant with a newly developed and coated stirrer is planned for 2019.

Services offered

- Characterization, development, optimization of stirring devices

- Application-oriented materials development

- Characterization of tribological and corrosive effects