Suitable active and inactive materials (adhesives, separators, housings) are prerequisites for new cell concepts. Long-lasting batteries with good cycle stability, high energy and/or power density, which are cost-efficient and safe, require the understanding of very diverse battery materials with varying material and electrochemical properties. These materials need to be adjusted to each other, optimized and adapted to suit the respective application.

The "Cell and Process Development" working group can provide its vast competence when it comes to analyzing the suitability of various components. In particular, the characterization of the performance of active materials through the construction of test cells and electrochemical assessment (performance, long-term testing) is a major focus of the group’s work. Beside materials from different commercial manufacturers, novel materials and materials from recycling processes were also assessed in the past.

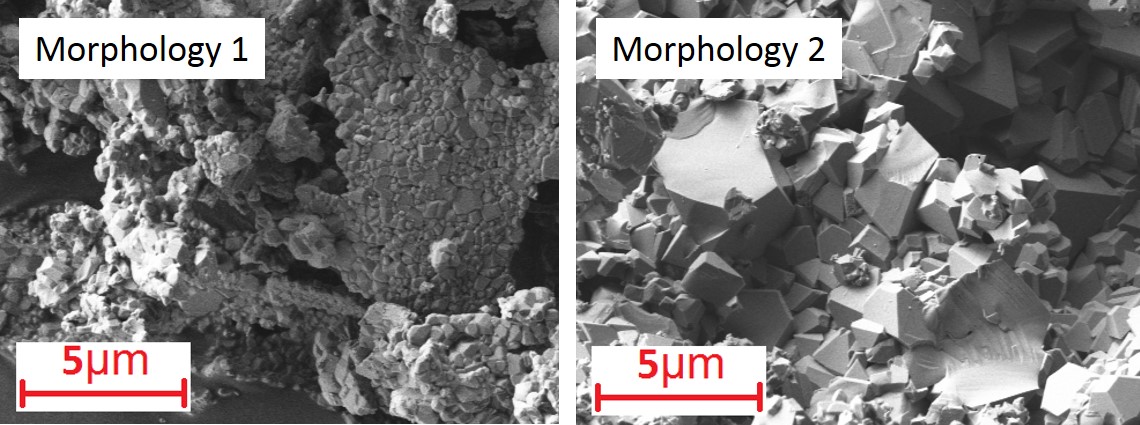

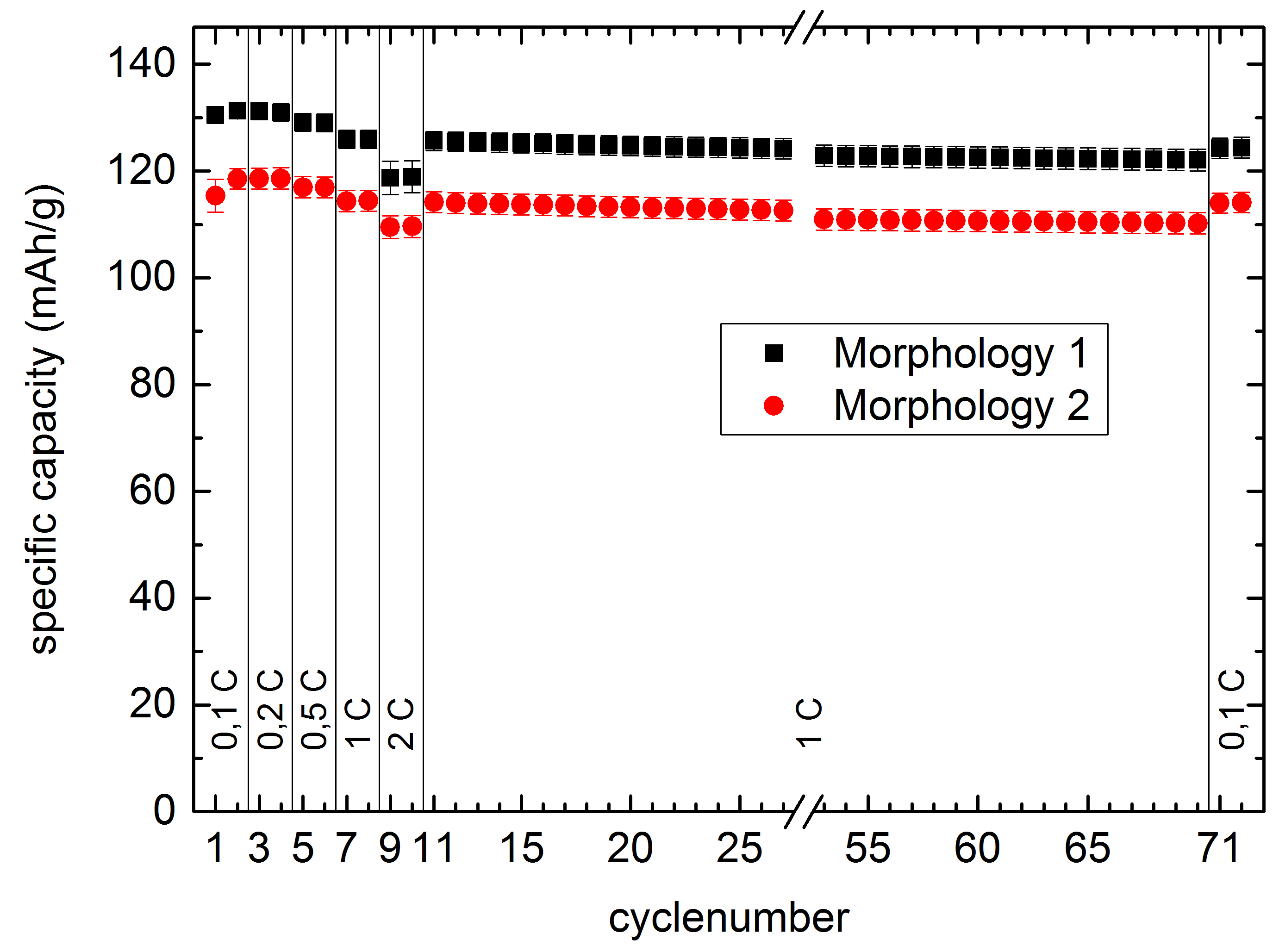

This work was based on the group’s own synthesis work or on cooperative efforts. For instance, the group worked on the optimized synthesis of LiNi0.5Mn1.5O4. This high-voltage cathode material intercalates and de-intercalates lithium at 4.7 V voltage while side reactions with the liquid electrolytes occur. In order to reduce these reactions and allow the creation of a suitable interface with novel solid electrolyte, the morphology, specific surface and particle size distribution are adapted to suit each other.

Services offered

- Assessment of batteries with regard to suitability and properties

- Benchmarking of active materials

- Development of recovery concepts, in particular for active materials

- Adaptation of cathode materials to optimize their electrochemical properties