Full-volume quality control and online evaluation of carbon fiber fabrics

Current research

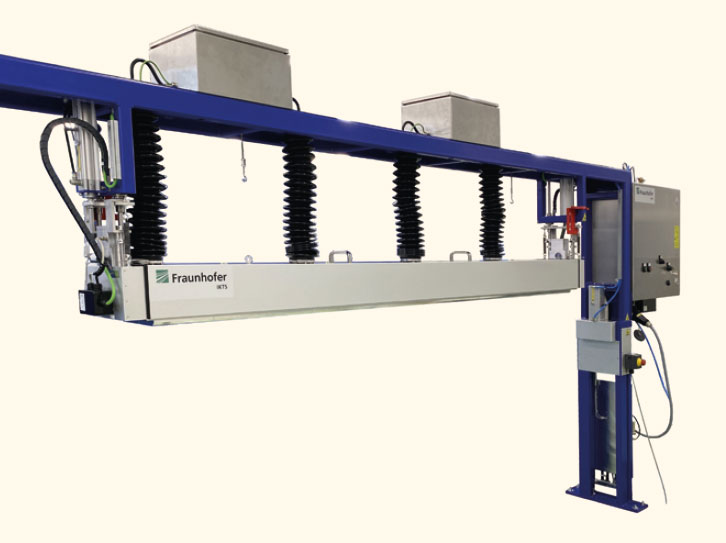

Multiaxial high-performance carbon fiber (NCF) cannot yet be fully inspected inline. The available optical methods do not allow a view of hidden layers and thus of invisible defects in the material. This concerns in particular the hidden 0°-orientated layers. Therefore, a multi-channel eddy current system was developed at Fraunhofer IKTS, which tests CF textiles non-destructively inline, at high speed and full production width.

Proven basis

The industry-proven EddyCus® Pro-II measurement system by Fraunhofer IKTS is the cornerstone of this new technology. It enables the detection and evaluation of hidden carbon fiber layers inside a multiaxial layer structure. The modularly expandable sensor elements allow production widths of up to 101 inches to be inspected without blind pixels, inline and at production speeds of up to 5 m/s. The system can classify metallic contaminants and sewn-in carbon fiber fluffs clearly, in addition to automated gap detection, defect size evaluation and fiber orientation measurement. The inspection system records information of the conductivity state in real time while maintaining high lateral resolution – contactless without damaging the material. This is made possible by combining several eddy-current channels with sensor-integrated multiplexers and a powerful edge server for data analysis.

Applications

- Inline production monitoring of up to 101 inch width during the production of NCF plies (for gaps, undulations, ply build-up, inclusion of foreign material) especially in hidden and non-visible layers

- Inline inspection of layer and wall thicknesses and electrical layer resistance of high and low conductive layers on wafers, battery tapes, conductive coatings on glass and plastic in nanometer resolution

Properties of the test system

- Cascadable system with channel multiplex rate of up to 100 KS/s

- Consisting of 4 EddyCus® Pro-II devices and 12 array sensors

- Up to 25 MHz eddy-current excitation frequency with integrated multiplexer

- Maximum pixel resolution: 0.853 mm

- ATEX-compliant for zone 21 (IP 68)

- Temperature compensation

- Data analysis and system control through included edge server

- Optional Ethernet-based OPC-UA for smart factory applications

- Analog and digital I/O for communication with production line

- Algorithms for automated calibrations especially for inhomogeneous and anisotropic materials, such as NCF (non-crimp fabrics)