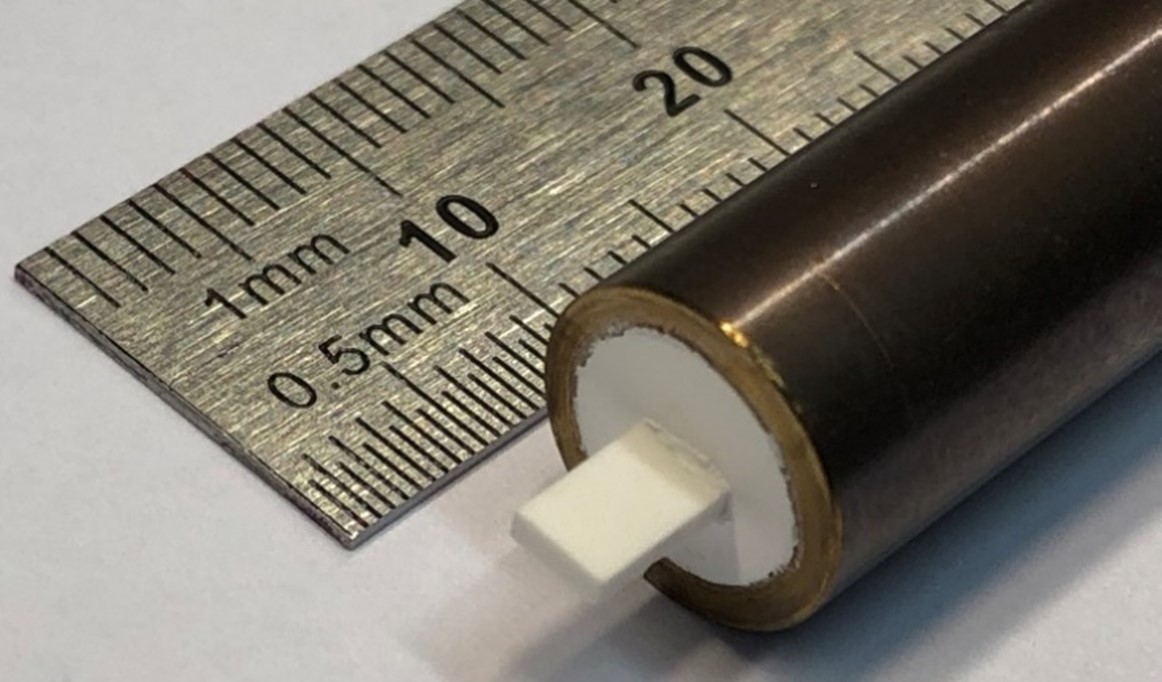

With the aid of the powder-based tamping process, ceramic sensor elements can be easily integrated into metallic receptacles. Here, the joining of a ceramic sensor element in a metallic tube is realized by pressing in steatite powder. Complex geometries can also be implemented using sophisticated tools.

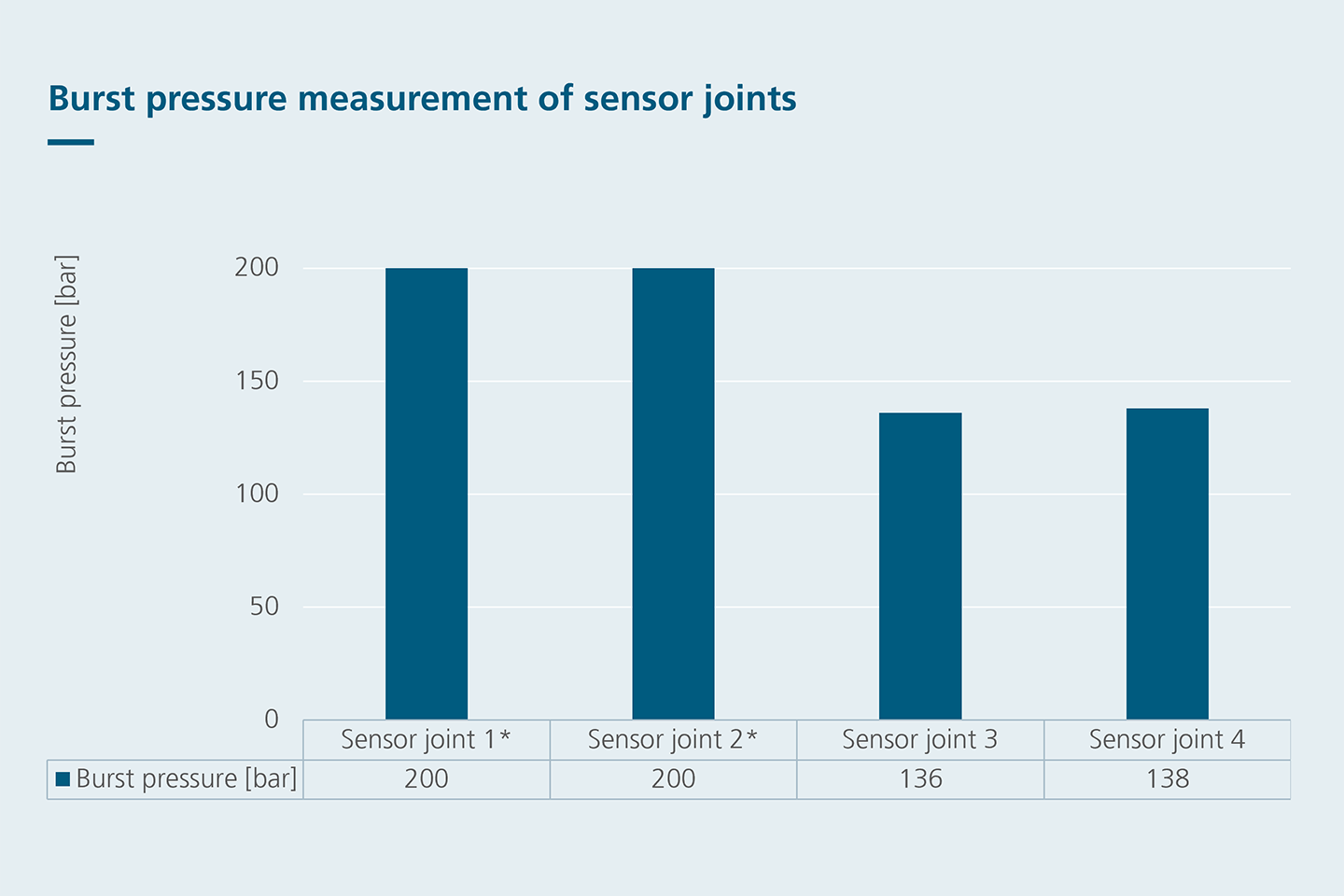

The joint is produced at room temperature. Due to the thermal stability of the joint, subsequent application temperatures of over 500 °C are possible. Due to the moderate stiffness of the joining material, even thermomechanically mismatched materials can be reliably joined together, resulting in high thermal shock resistance. The joining process is also suitable for connections in the range of increased pressures (e.g. for pressure sensors).

Key components for successful joining are the tamping tools. These must have suitable geometries, high geometric accuracies and at the same time high hardnesses.

Technical data

- Temperature stability > 500 °C

- Pressure stability greater 100 bar

- High thermal shock resistance

- Corrosion resistance

- Attractive mechanical stabilities achievable

Services offered

- Development of solutions for joining ceramic sensors

- Use of different ceramic/metal variants possible

- Advice on material selection

- Plugging of single sensors up to production of small series

- Technology transfer