Materials and Process Analysis

Methods and technical equipment

Analysis of ceramic raw materials and processes

- Chemical and phase composition (XRF/XRD)

- Particle size and shape analysis in the nano- to millimeter range

- Suspension characterization (rheological properties, surface conductivity, suspension stability)

- Thermal analysis as well as thermophysical and chemical properties (TG/DTA DSC, dilatometry including gas analytics in a wide variety of atmospheres from -150 °C to 2400 °C)

Structural and microstructural analysis

- Standard methods of ceramographic preparation

- Ion beam preparation techniques (BIB/FIB)

- High-resolution analysis of microstructures and surfaces using FESEM (EDX, WDX, EBSD)

- TEM cross-sectional analysis including EDX, EELS, EFTEM

- X-ray computer tomography in the micro- and nano-range, X-ray microscopy

- Pore distribution (Hg porosimetry, permeation porosimetry, N2/Kr adsorption and N2/Kr desorption, pycnometry)

- X-ray diffractometry, from room temperature to 1400 °C

Physical properties of materials and components, from room temperature to high temperatures

- Mechanical strength, fracture toughness, elastic constants and hardness up to 1550 °C

- Nanohardness, local elastic properties (AFM, AFAM, nano-indenter), adhesion strength

- Properties of porous and highly porous materials (e.g. membranes, particle filters, catalysts)

- Thermophysical properties (including heat conductivity, heat capacity, thermal expansion coefficient)

- Electrical and dielectrical properties (specific resistance from μΩcm to 1015 Ωcm)

Corrosion and tribological properties

- Corrosion in solutions (T < 250 °C, pressure up to 35 bar) and gases (T < 2000 °C), hot gas testing (burner test stands up to 1500 °C, gas velocity up to 100 m/s)

- Electrochemical characterization

- Tribology and wear (oscillating sliding testing at room temperature and higher temperatures, abrasion testing)

Quality and safety testing

- Climate chambers (-80 °C to 1000 °C), salt spray chamber

- Unicameral and bicameral temperature shocker

- Vibration test stand for 600 kg and 200 g

- Specific contact resistance, surface resistance, dielectric strength, creeping and dielectric properties

Accredited laboratories (DIN EN ISO/EC 17025)

- Thermoanalysis and thermophysics

- Particle and suspension characterization

- Laboratory for quality assurance and reliability

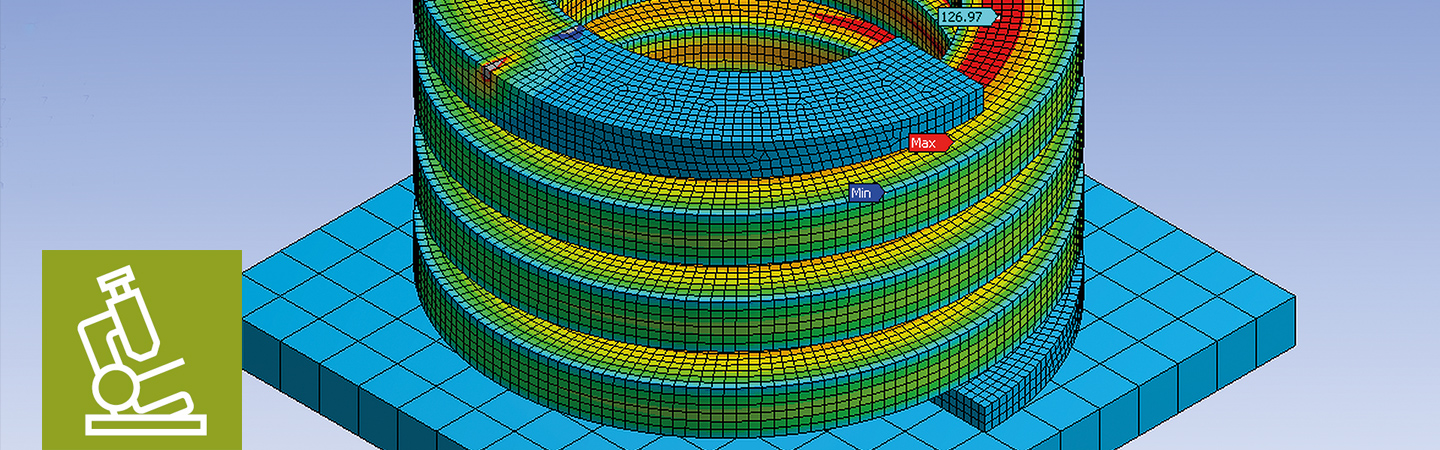

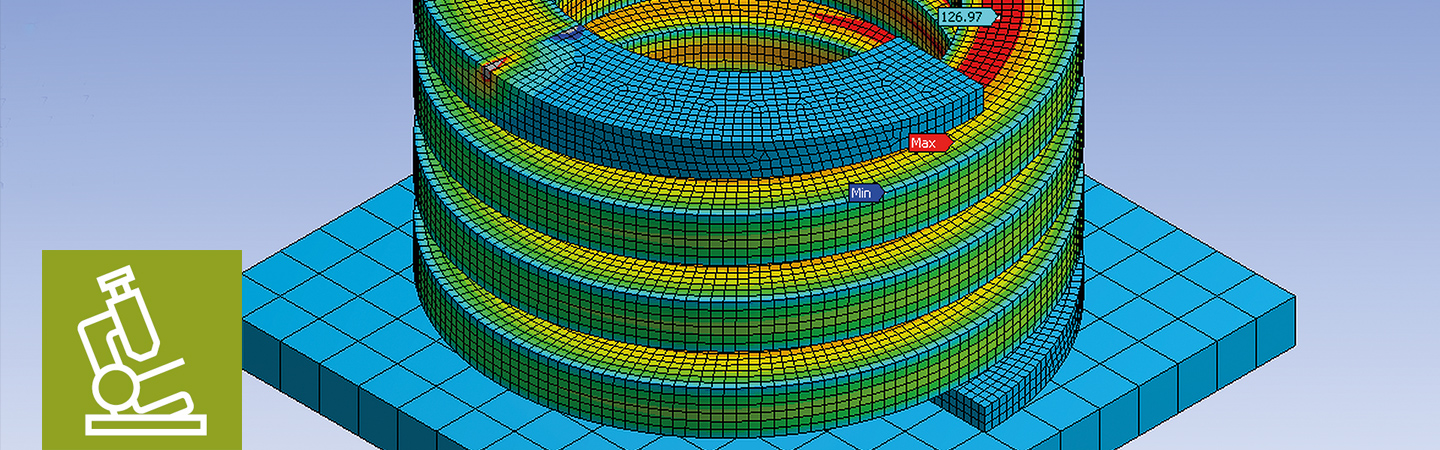

Modeling and simulation

- Finite element analysis (FEM): ANSYS (Emag/Mech), COMSOL Multiphysics, FlexPDE, Atila

- Flow velocity simulation: Fluent

- Systems simulation: Matlab/Simulink, Simulation X, Dymola/ Modelica

- Thermodynamic simulation: FactSage