Waste water without pharmaceutical residues – New process completely eliminates trace substances

Pharmaceutical residues in waste water pose new challenges for municipal water treatment. Established methods are frequently found lacking when it comes to removing such substances. A treatment module developed at Fraunhofer IKTS provides a remedy and completely eliminates these harmful substances.

In Germany, approximately 38,000 tons of medicines, including hormones, antibiotics and antivirals, are consumed annually. Their residues are increasingly found in the waste water of conurbations. From there they also enter ground- and surface water. Ususally they are difficult to remove with conventional sewage plant and water treatment technology. Two very worrying trends are associated with this: the increasing of both the spread of multiresistant microorganisms and fertility disorders.

With the help of electrochemical processes, pharmaceutical residues can be completely degraded. They are electrochemically converted at the anode of an electrolysis cell, leaving only carbon dioxide. However, the anodes made of boron-doped diamond with a price of currently approx. 16,000 € per square meter are much too expensive. Fraunhofer IKTS is pursuing two approaches in order to manufacture the electrodes more cost-efficiently and increase the degradation rates.

Cost-efficient anode materials in combination with ultrasound

On the one hand, an alternative noble-metal-free anode material of semiconducting mixed-oxide phases was developed. Tin-antimony oxide-based systems have proven to be particularly effective. With the same functionality and service life, they cost only one tenth compared to boron-doped diamond.

On the other hand, researchers at Fraunhofer IKTS cause the waste water to oscillate by means of ultrasound in order to intensify the mass transport at the electrode and thus reach even higher degradation rates. This is achieved by minimizing the thickness of the diffusion layer on the anode. The layer acts as a kind of reaction barrier and thus slows down their destruction.

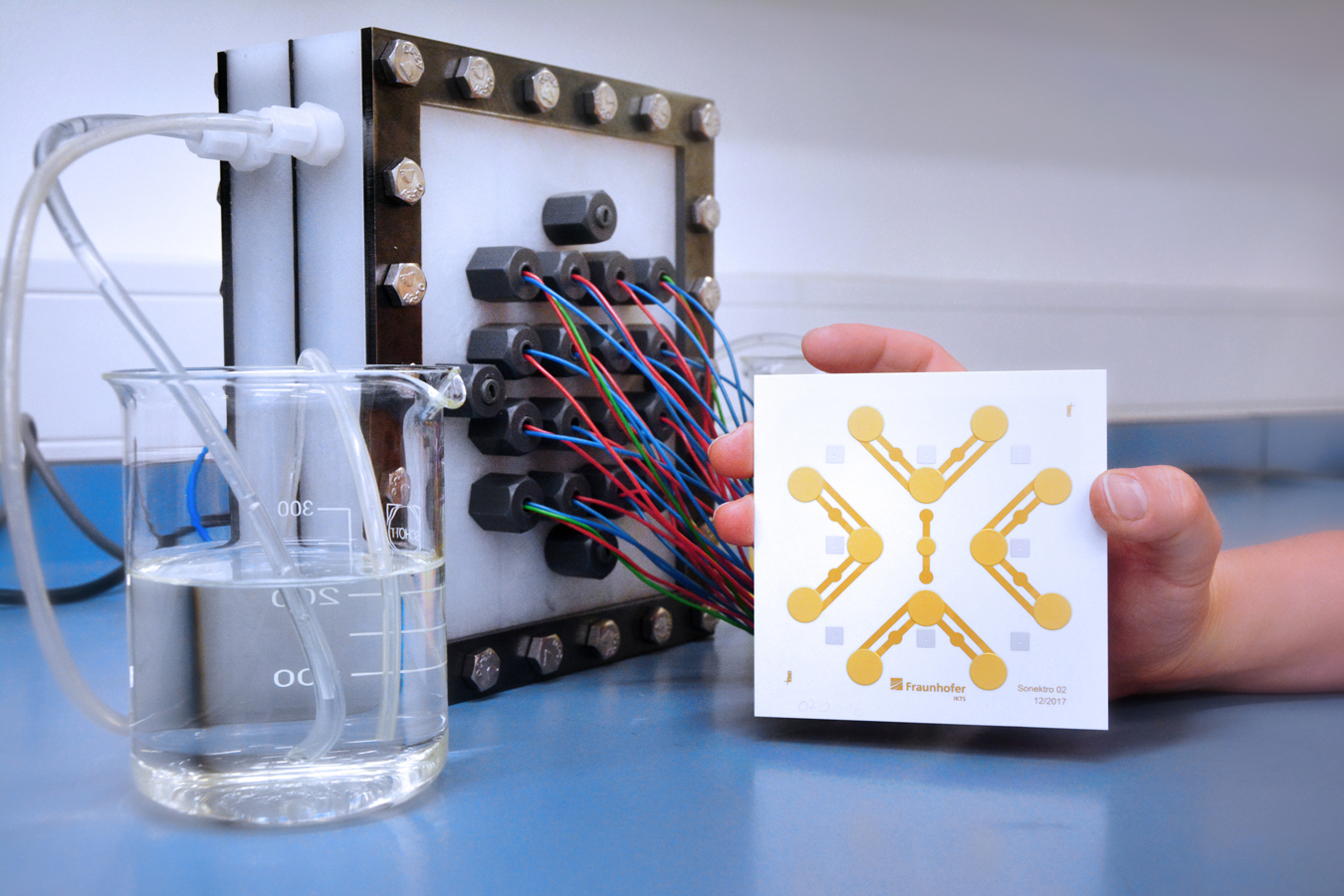

Ceramic-based electrode-sonotrode module

Not only the process combination is sophisticated, but also the design of the corresponding electrode-sonotrode module. The innovative approach consists of pressing the ultrasonic sensors directly onto the ceramic electrode so that it vibrates like a spring. This greatly improves material transport to the electrode. This is made possible by ceramic materials and technologies. Fraunhofer IKTS covers the entire technological chain – from the development of functional materials, screen printing of ultrasonic actuators, suitable joining technologies for contacting the electrode to systems integration. In addition, there is extensive know-how in the field of electrochemical process engineering, which forms the basis for the successful treatment of polluted waste water. These intertwined competences of a research institute are unique in Europe.

On a laboratory scale, a convincing proof of the function of the new electrode-sonotrode module has recently been provided and a patent application has been filed. “In view of the positive results, we now see upscaling as a realistic goal. An electrochemical reactor is being developed and tested on a technical scale for this purpose,“ says Dipl.-Chem. Hans-Jürgen Friedrich, head of Technical Electrolysis and Geothermal Energy group at Fraunhofer IKTS in Dresden. In the future, the electrode-sonotrode module will also be used in other sectors, such as the destruction of nitroaromatics, plasticizers, herbicide residues or other toxic substances in commercial waste water. “Applications in the field of chemical synthesis and sensor technology are also focused,“ adds project manager Hans-Jürgen Friedrich.

At this year‘s IFAT, Fraunhofer IKTS presents its entire portfolio of efficient and environmentally friendly water treatment technologies on Booth 132 in Hall A3.

Acknowledgement

We would like to thank the Federal Ministry of Education and Research BMBF for the funding of the joint project "SONEKTRO" as part of the "InnoEMat" funding initiative.

Supported by