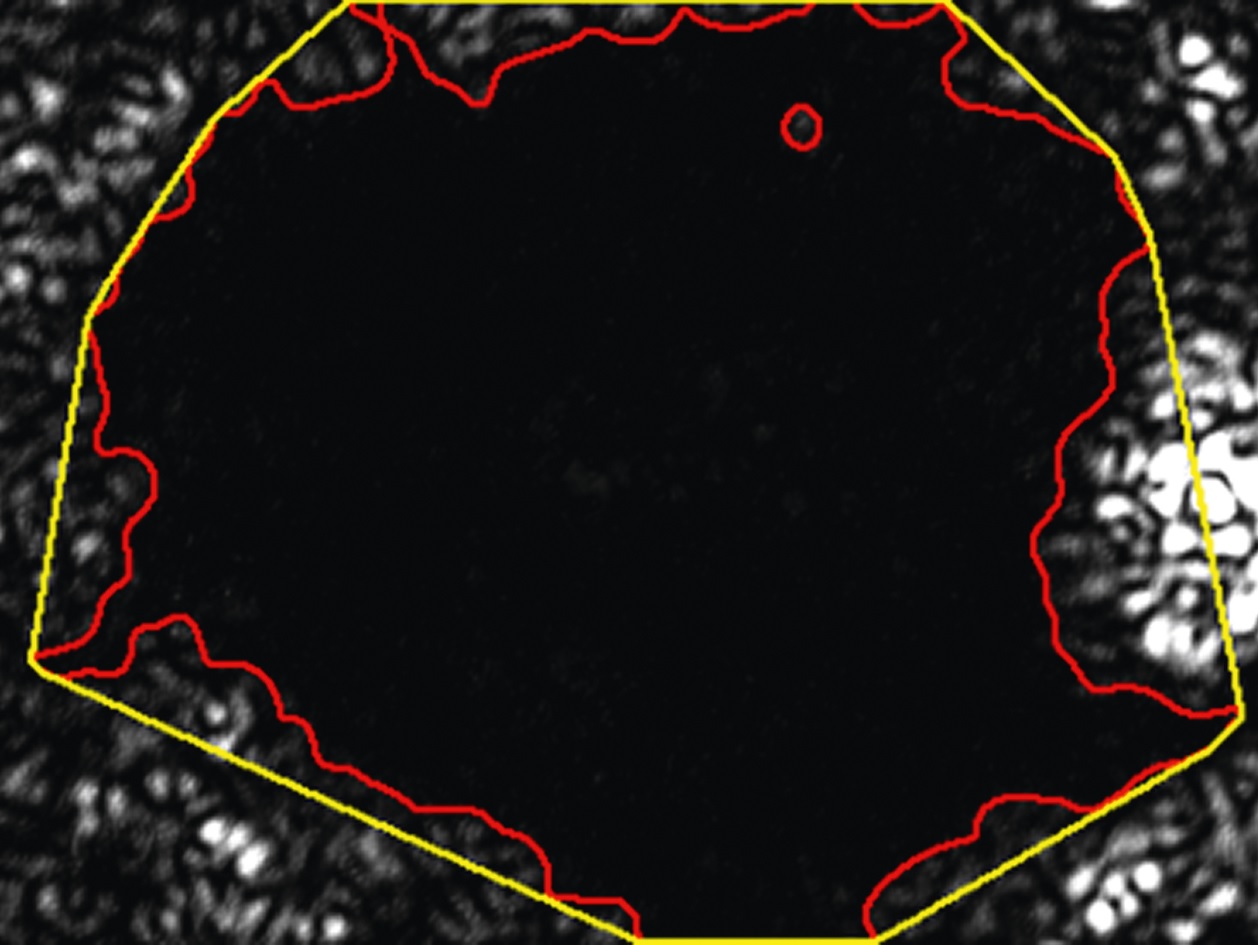

In electrical engineering and electronics applications in which electrical contacts are only selectively required (e.g. grinding and plug contacts), micro-laser cladding is used for local selective application of contacts with precious metals. Mass production requires quality control of the contacts with the potential for high-speed inspection. Laser speckle photometry (LSP) can be used for this purpose. LSP is a contactless inspection method that was developed at Fraunhofer IKTS. It is based on the analysis of temporal changes in optical speckle patterns (interference patterns) resulting from exposure of test objects to coherent light. In a joint project of Fraunhofer IKTS and ILT, use of LSP for indirect determination of the precious metal content as well as the geometry of the contacts is being examined.

The gold contacts are applied by needle dispensing, dried to drive off the binder, and remelted with a laser. In LSP, the necessary temporal and lateral resolution of the interference pattern is achieved through use of a CMOS camera. Interference excitation is simultaneously effected through reheating of the contacts with the machining laser.

Pulse processing enables a gold contact with a diameter of about 200 microns and a thickness of several 10 microns to be remelted within 100 milliseconds. By parallelization (e.g., by a cascading beam splitter), dozens of contacts can be functionalized per second. The LSP signals change with the gold content and the diameter and height of contacts and can therefore be used as a parameter for calibration. Currently an accuracy of approximately ± 7 % can be achieved. Exemplified by the parameter “contact height“ the correlation between the measurements obtained using a reference method and LSP is shown in the diagram below. Up to 100 contacts per minute can be recorded and evaluated externally, making 100 % inspection possible in principle. Micro-laser cladding and LSP have been successfully tested in an experimental setup.

The project was funded within the Fraunhofer program MEF.