The IKTS project group "Cognitive Material Diagnostics" is currently working on three BMBF projects in Cottbus for the benefit of the region.

Artificial intelligence for safeguarding know-how on conveyor belt systems

In the "Data-based services" project, Fraunhofer IKTS is recording the know-how on conveyor belt systems in Lusatian open-cast mines so that these competencies are not lost in the upcoming coal phase-out. Artificial intelligence is used to secure the many years of experience, to apply it in a targeted manner for the reorientation of the affected companies in the structural change region of Lusatia, and to make it available to other companies. Partners working on the project are ABB AG, LEAG Lausitz Energie Kraftwerke AG as well as EWG Automation GmbH.

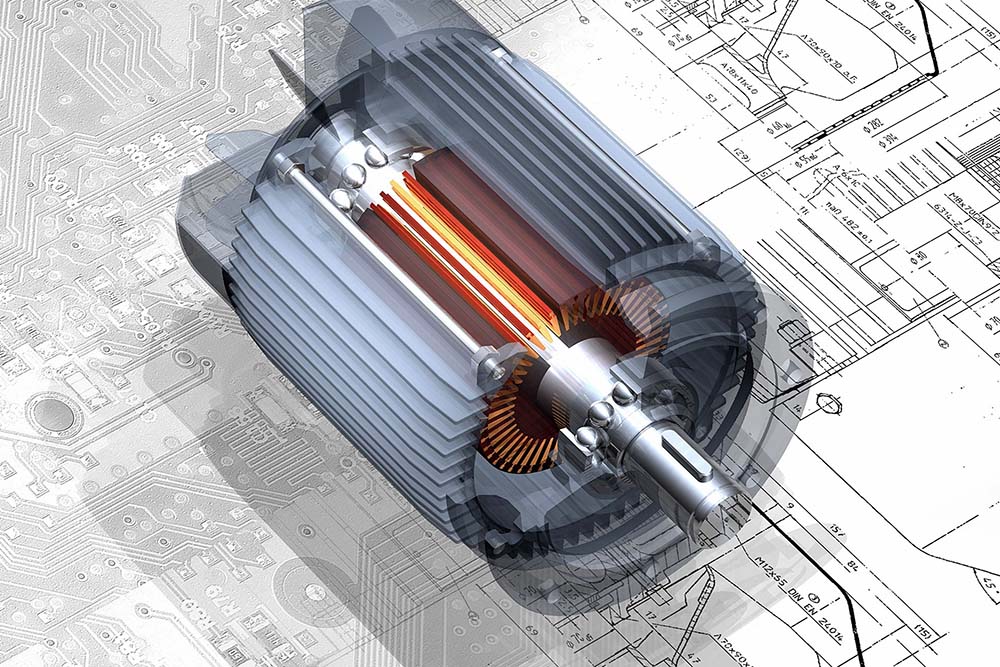

Digital twins for process optimization and predictive maintenance

In the "Digital twins for process optimization and predictive maintenance" (DIZPROVI) project, IKTS researchers together with partners develop a system for planning and optimizing operating modes and maintenance measures in industrial plants – also outside the power plant area. Involved in the project are ABB AG, LEAG Lausitz Energie Kraftwerke AG, the regional companies CombTec GmbH and EMIS Electrics GmbH as well as Zittau/Goerlitz University of Applied Sciences and XRG Simulation GmbH Hamburg.

Intelligent information processing for process optimization and increased efficiency

Together with the BTU Cottbus-Senftenberg, IKTS researchers develop Methods and algorithms for modeling continuous industrial processes and analyzing large data sets in the BMBF project "Intelligent information processing" (IntelliInfo) using artificial intelligence. The results can be used to optimize processes and increase efficiency.