Author: Susanne Freund

Surface finishing and functionalization

As research and technology service provider the Fraunhofer Institute for Ceramic Technologies and Systems IKTS develops solutions for highly stressed components in mechanical and plant engineering as well as medical, energy and environmental technology. Particular challenge is to reliably apply ceramic materials on other material systems. This long-year know-how is used in various fields of surface finishing and functionalization. Some selected examples are summarized below.

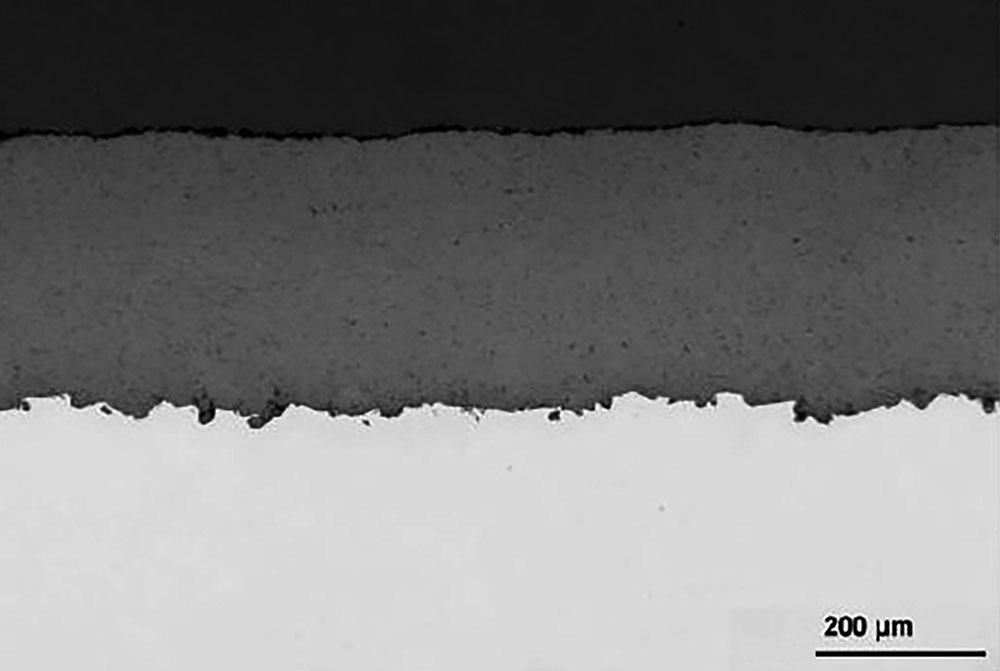

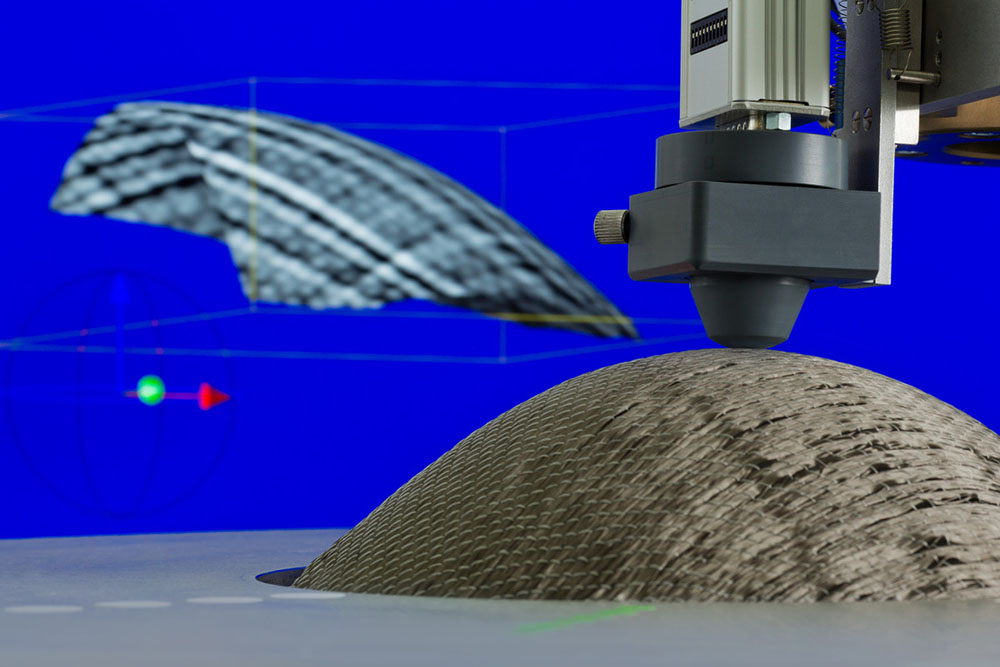

Ceramic protection layers for surface finishing of CFRP/GFRP components

Ceramic coatings can significantly improve the surface resistance and quality, for example, with regard to wear, non-stick or insulation behavior. Depending on the load, the lifetime of CFRP/GFRP components can be extended by a factor of 100 using ceramic wear-resistant coatings.

Thermal spraying of ceramic suspensions for very smooth surfaces

Using ceramic suspensions for thermal spraying instead of powders, thin coatings (< 100 μm) with very smooth surfaces can be realized. Additionally, raw materials as well as necessary finishing steps for coated surfaces can be either reduced or eliminated altogether.

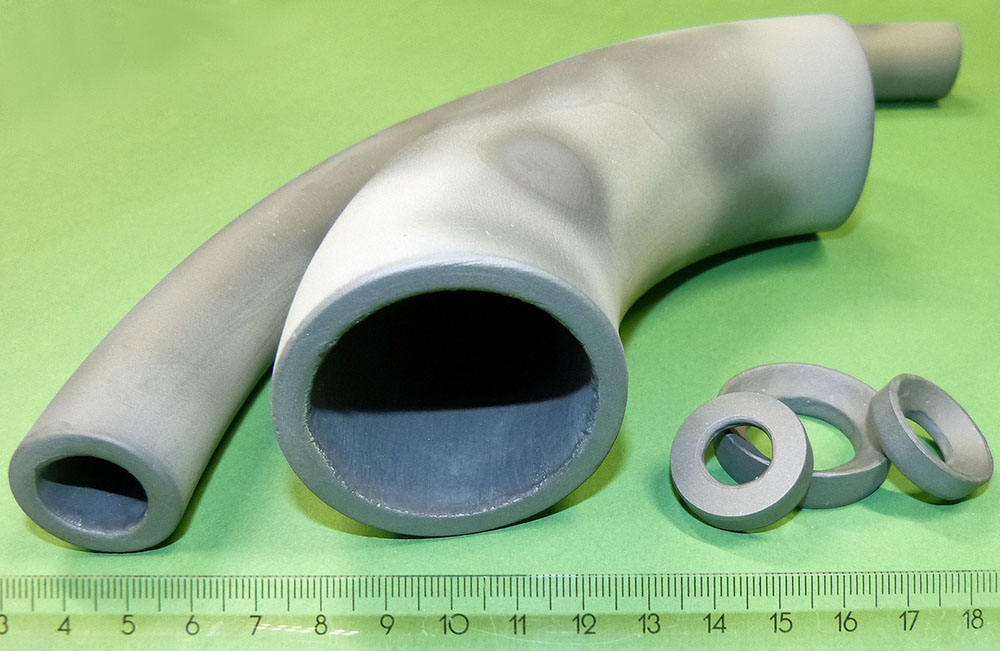

Super hard, corrosion-resistant diamond-ceramic coatings for highly stressed components

Using diamond ceramics, damage caused by corrosion and wear can be avoided. The new material can be produced as 300 to 500 µm thick surface layers in highly stressed component areas. The wear resistance is more than ten times higher than for commercial boron carbide materials and similar to that of super hard polycrystalline diamond (PCD).

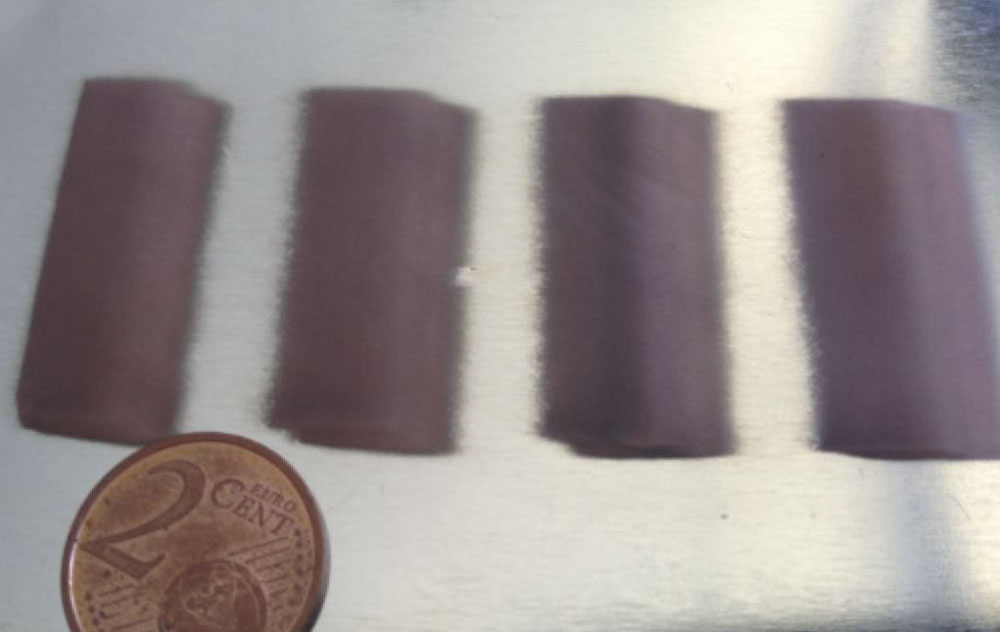

Nano-composite coatings for surfaces with combined properties

The combination of plasma-sprayed coatings and a nano-composite sealing allows for a number of new applications in mechanical and plant engineering as well as medical technology. Using sol-gel technology, dense and thin nano-composite coatings (thickness < 10 μm) with various property combinations can be realized. Virucidal surface coatings which stop the transmission of infection due to their properties are only one approach.

Nano-composite coatings for surfaces with combined properties

Ultra-thin barrier coatings and systems for hygroscopic and easily oxidizing powder materials can improve their property profile during application. For the production of hardmetal tools, for example, a TiN barrier coating can improve the hardness as well as the fracture toughness. Li-ion batteries are another application. With coated LNMO powders the cycle stability as well as the performance of batteries can be increased.

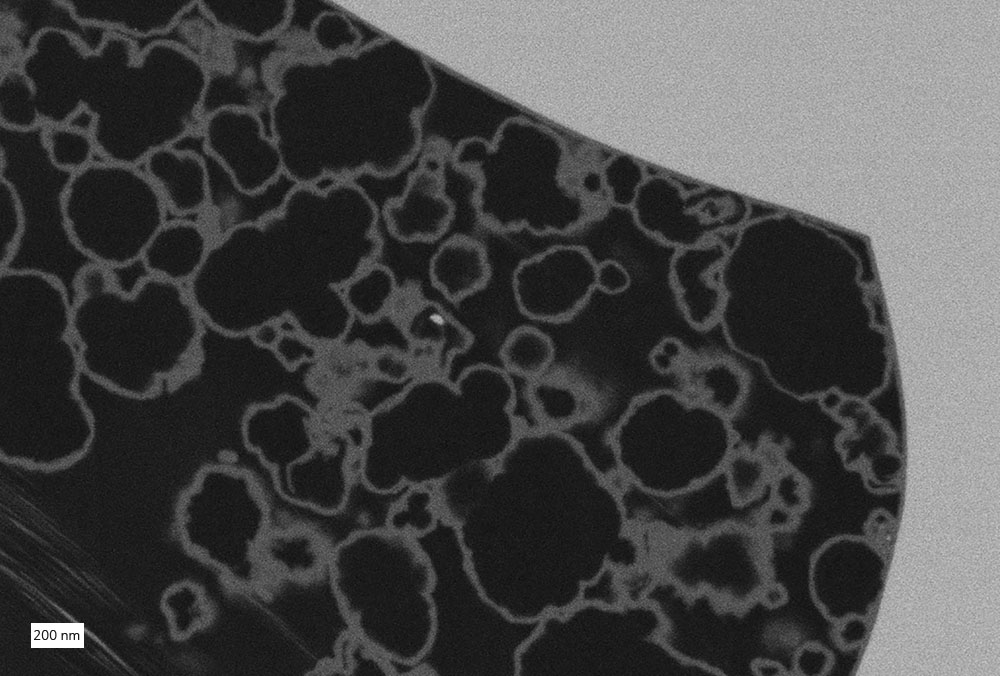

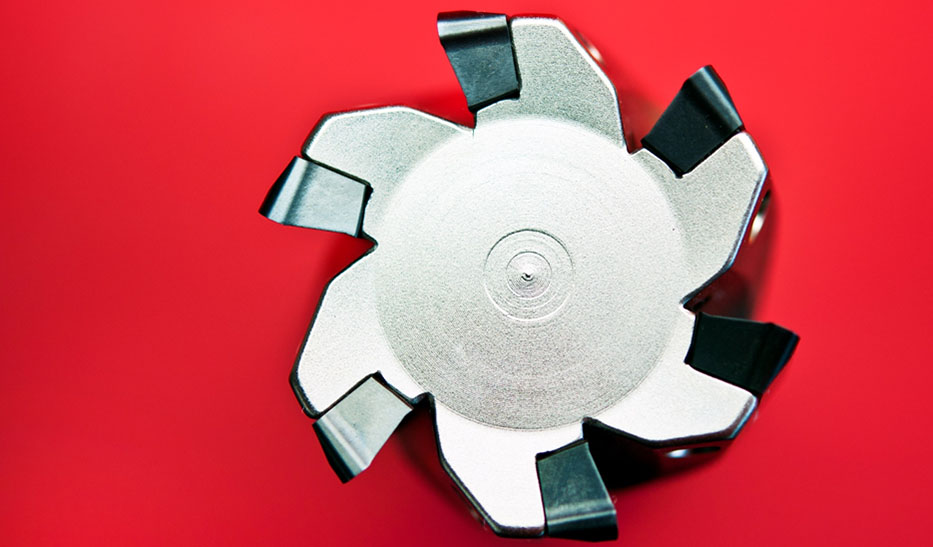

CVD hard coatings for wear-resistant tools

The machining of new materials such as high-strength cast iron and fiber composite materials requires a permanent improvement of both, the tool and the coating materials.

Chemical vapor deposition (CVD) is one of the most important basic technologies for the manufacturing of thin wear-resistant coatings.

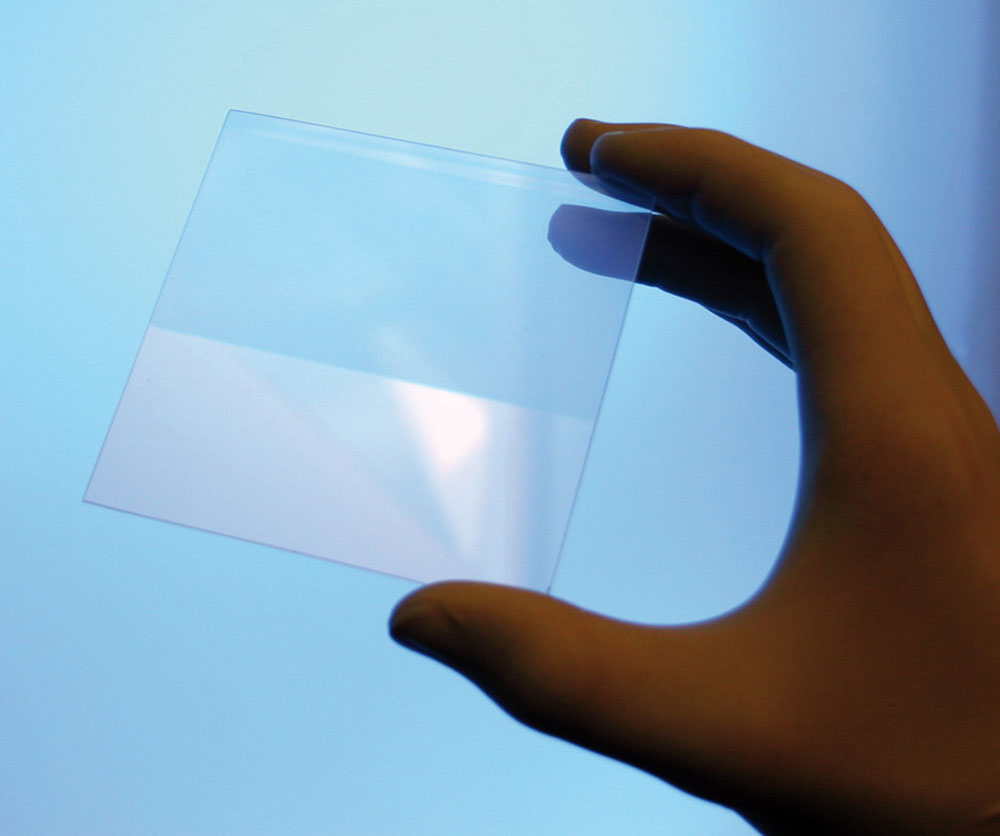

Antireflex coating for transparent ceramics

Using fluorolytic sol-gel synthesis nanoscopic metal fluoride can be applied as antireflex coating on transparent materials such as glass, plastics or ceramics. The new nanofluoride antireflex coating on transparent ceramics offers the potential to improve the transmission as well as to adjust specific spectral bands and maximum values of transmission.

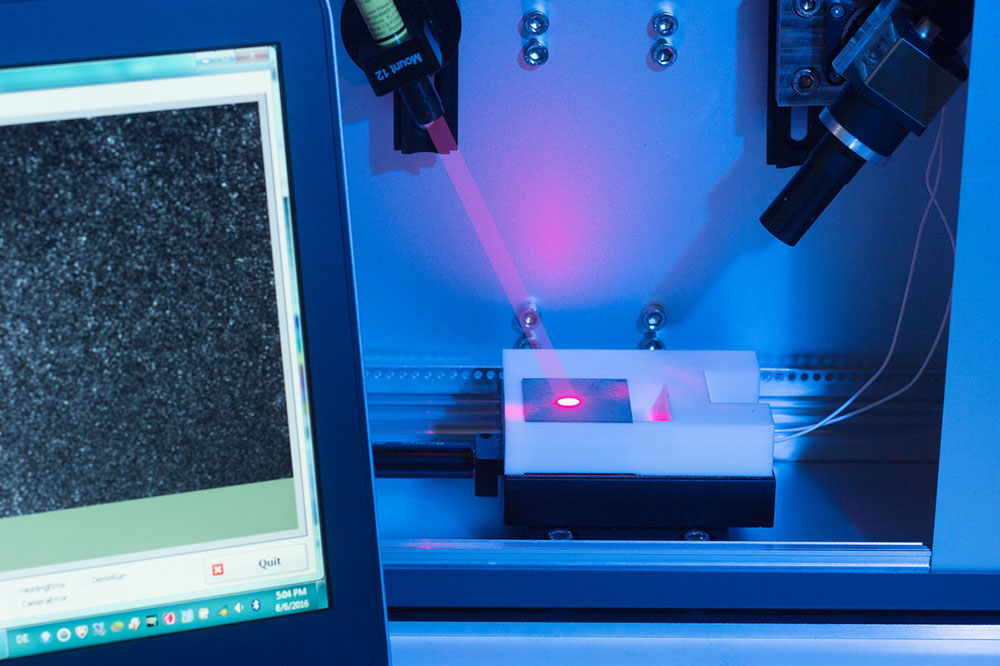

Non-destructive testing for quality assurance in coating processes

Time-resolved laser speckle photometry (LSP) is a new method that was developed at Fraunhofer IKTS to characterize part surfaces. The non-contact method is characterized by a simple, robust design and low costs compared with those of competing measurement methods. The extremely short measurement times predestine it for in-line use in industrial production. Laser speckle photometry is highly sensitive to out-of-plane and in-plane displacements.

High-frequency eddy current methods

The eddy current method is an electromagnetic technique for non-destructive testing of metal and non-conductive or weakly conducting material surfaces. It has become a key technology for quality assurance because of its high speed, operation without a coupling medium, no requirements regarding radiation protection, and ease of integration into industrial manufacturing processes.

Stay informed: You are welcome to subscribe to our newsletter, read our other blog articles and follow us on LinkedIn, Instagram and YouTube.