Ethanol-fired fireplaces are popular since they can be operated in the domestic area in principle without a chimney or other exhaust systems. They also require little space and are quite inexpensive. Since ethanol-fired fireplaces currently do not have an integrated exhaust gas purification system, users are directly exposed to the pollutants emitted, such as benzene, formaldehyde, carbon monoxide and nitrogen oxides. This can potentially cause health problems. In addition, there are dangers associated with filling the burner while it is still hot. In the past, this repeatedly led to dangerous deflagrations when refilling or igniting the fireplace.

Within the project "Clean EtOH-fire" (development of an emission-minimized combustion system for (bio-) ethanol), a system for the pollutant-free and operationally safe combustion of ethanol was developed together with industrial partners. This can be used not only in the domestic or commercial sector (restaurants, hotels and events), but also as a supplementary CO2-neutral chimney heating system in low-energy houses.

Fraunhofer IKTS has developed a catalyst concept for this purpose based on its extensive know-how in the field of engine and industrial exhaust gas purification. On the one hand, this enables a reduction of pollutants at very low reaction temperatures and, on the other hand, an optimal flow distribution of the reaction gases within the catalyst support. Furthermore, it does not require any additional auxiliary energy and has a long service life.

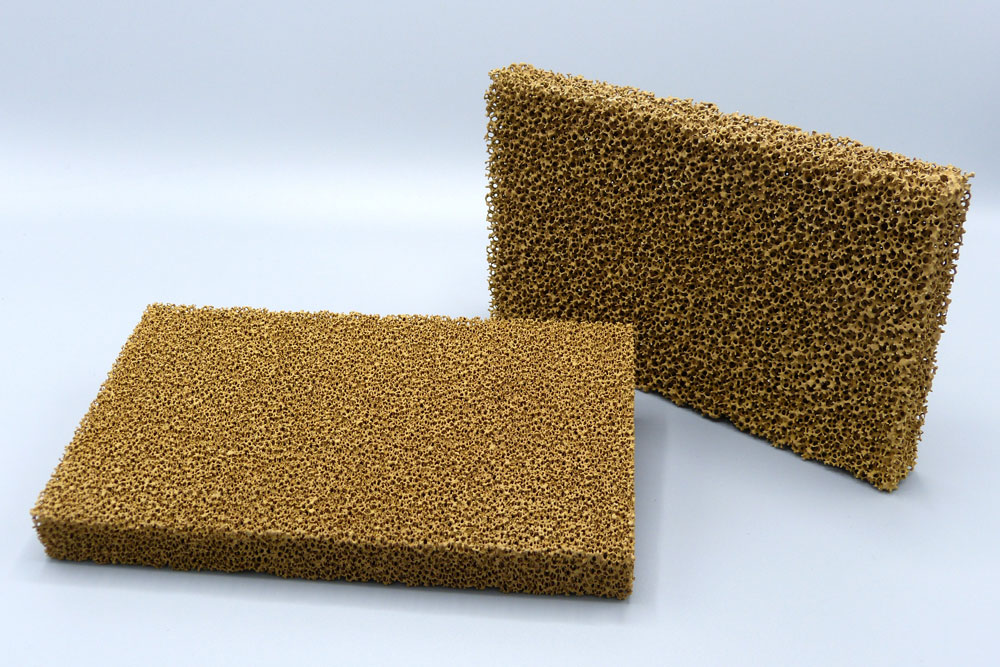

The catalyst support is based on cellular ceramics, which, in contrast to catalyst beds, have only low back pressure. At the same time, the network-like structure allows long residence times of the pollutants on the catalyst, which is a major advantage over catalyst honeycombs. Open-cell foam ceramics are produced by molding reticulated polymer foams using the so-called Schwartzwalder process.

The catalysts are adapted to the special operating conditions of ethanol burners and the catalyst support in order to achieve high conversion rates under the given temperature and exhaust gas conditions. This includes the synthesis and functionalization of the catalyst materials as well as their processing to suspensions with which homogeneous and crack-free layers can be realized on the catalyst support. As a result, benzene, formaldehyde and CO emissions can be reduced simultaneously when the exhaust gas comes into contact with the catalyst.

Services offered

- Development of suitable catalyst supports made of cellular ceramics

- Synthesis of catalysts and process development for catalytic coating

- Laboratory tests on the application properties of coated substrates and evaluation of the catalytic behavior and long-term stability (catalysis test stands)

Acknowledgement

We gratefully acknowledge the Saxon State Ministry of Economics, Labour and Transport (SMWA) for funding the project "Clean EtOH-fire" from funds of the European Regional Development Fund (ERDF) and from taxes on the basis of the budget approved by the members of the Saxon State Parliament.

Project: Development of an emission-minimized combustion system for (bio-) ethanol (Clean EtOH-fire)

Duration: 2018/07/01 to 2020/12/31

Funding authority: Sächsische Aufbaubank (SAB)/ SMWA (EFRE)

Grant number: 100310615