X-ray methods

Modern X-ray methods can be used to address issues that are very difficult or impossible to solve using conventional NDT methods. X-ray methods are used at Fraunhofer IKTS Dresden wherever materials with high radiation absorption have to be penetrated. This allows volume tests and other investigations, e.g. on surface tensions, to be carried out on samples of a wide variety of materials and geometries. In addition to materials science investigations for industry, this also includes non-destructive examinations of archaeological finds, musical instruments, or art objects.

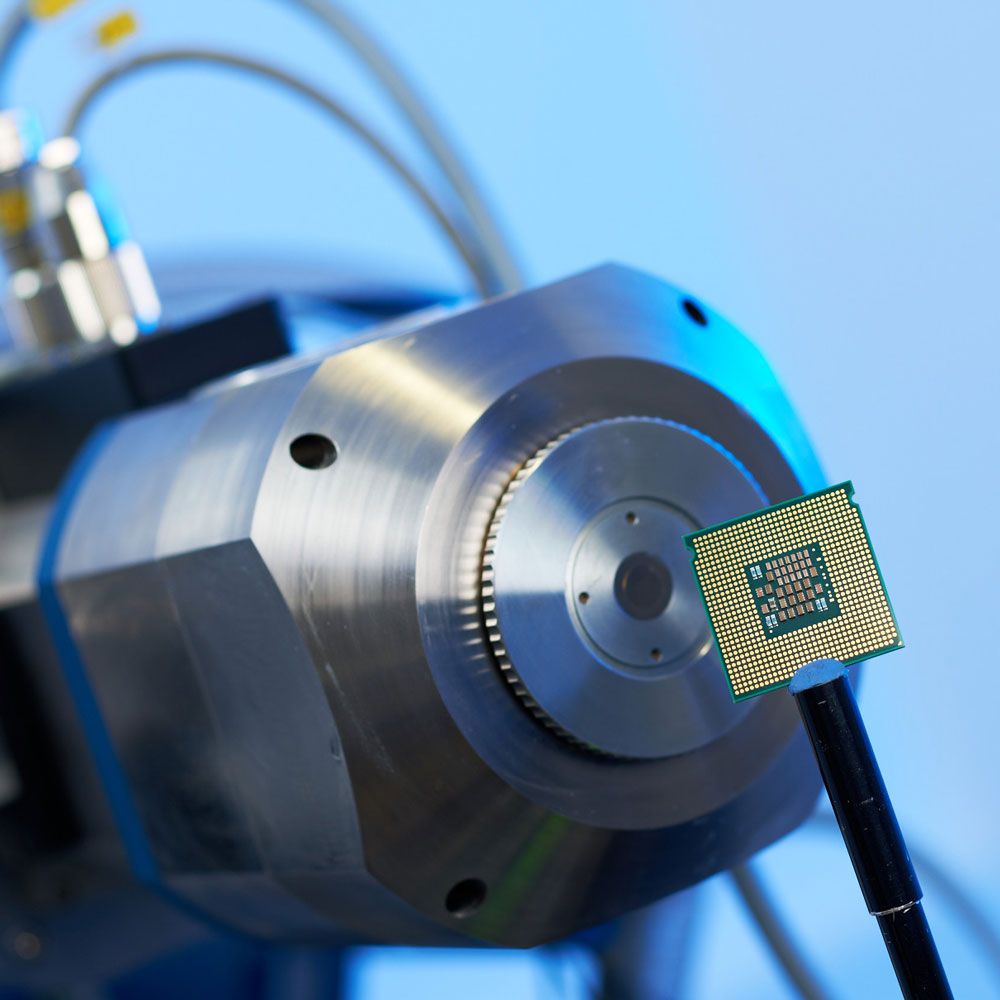

Micro-computed tomography

Micro-computed tomography (micro-CT) is used at Fraunhofer IKTS for the examination of industrial components and increasingly also of artistic and cultural goods. It is ideally suited to visualize pores, cracks or other material inhomogeneities with a high spatial resolution. The micro-CT system at Fraunhofer IKTS can be adapted to the respective inspection task or inspection geometry according to customer requirements.

Fields of application

- Material and product development for the electronics industry and medical technology

- Small-batch testing

- Testing of archaeological finds and art objects

High-resolution computed laminography

High-resolution computed lamination (HRCL) is a proprietary X-ray tomography technique developed by Fraunhofer IKTS Dresden, which can be used to examine small areas of large-area and planar circuit carriers with high resolution and non-destructively. Due to a modified measurement setup and an optimized reconstruction algorithm, no time-consuming sample preparation is required.

Fields of application

- Fast visualization of cracks or pores in joints of electronic components

- Inspection of systems embedded in CFRP components

X-ray diffraction

X-ray diffraction is a method used by Fraunhofer IKTS to determine the composition of mixtures of substances. In this process, X-rays are diffracted at ordered structures such as crystals or quasicrystals and the diffraction intensity distribution is measured.

In addition, Fraunhofer IKTS uses X-ray diffraction for the determination of residual stresses by the Sinus2y method. The sample is tilted in a reflex by a certain range y (Psi). In order to determine the distribution of residual stresses over the specimen, measurements are taken at various points, but at least in the extreme areas (edges, corners and center)

Fields of application

- Determination of the composition of material mixtures and of residual stresses in material and product development

- Studies to determine the causes of component defects