Membrane processes form the basis for energy-saving material separation processes in the chemical and pharmaceutical industries, biotechnology or even in the energy and water sectors. Membranes based on organic polymers or based on inorganic materials are successfully applied, but intrinsic properties of the pure organic or inorganic materials limit their wider use.

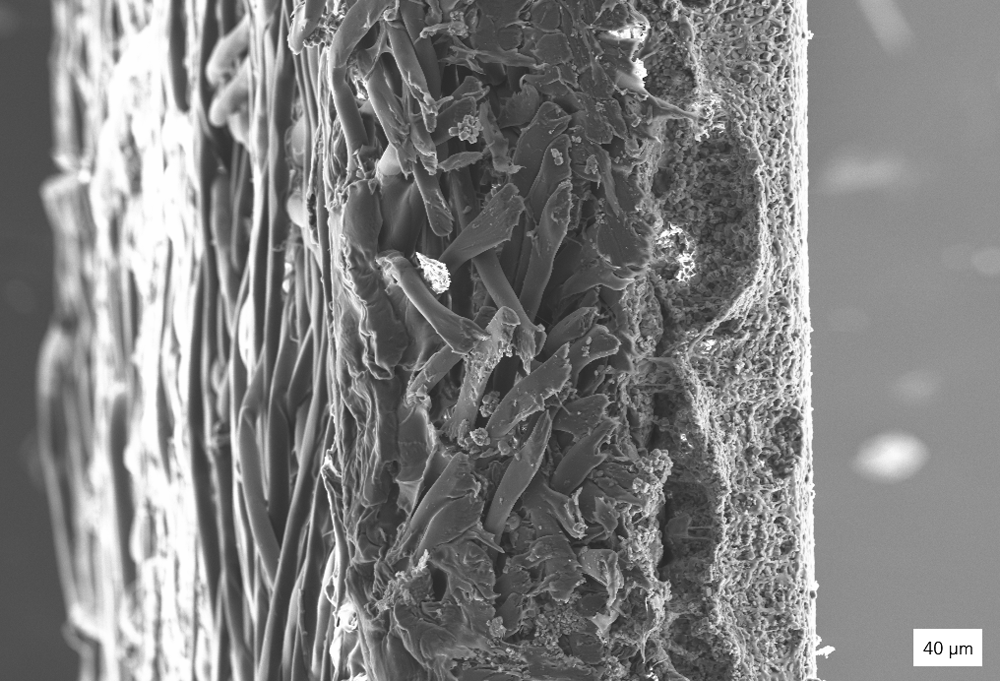

Therefore, the focus of the working group “Polymer and Mixed-Matrix Membranes” is on composite membranes, which combine the advantages of polymers with the separation properties of porous particles. For this purpose, micro- or nanoparticles are introduced as a dispersed phase into a polymer matrix (continuous phase) and processed into tapes or three-dimensional structures. In addition to conventional processes for tape production from polymers, we also use thermal as well as photochemical crosslinking reactions of prepolymers. Due to the high separation efficiency of special fillers, the disadvantages of pure polymer membranes in terms of selectivity and permeability can be overcome.

One expertise of Fraunhofer IKTS is the functionalization of the porous fillers. Through suitable surface functionalization, we adapt the wetting properties of the fillers to the chemical-physical properties of the polymer matrix in order to achieve optimal and stable dispersion. In addition, we improve the separation performance of the resulting mixed matrix membranes by using suitable fillers. We also functionalize the porous fillers using reactive groups, which leads to better crosslinking with the polymer matrix and thus higher stabilities of the mixed-matrix membranes.

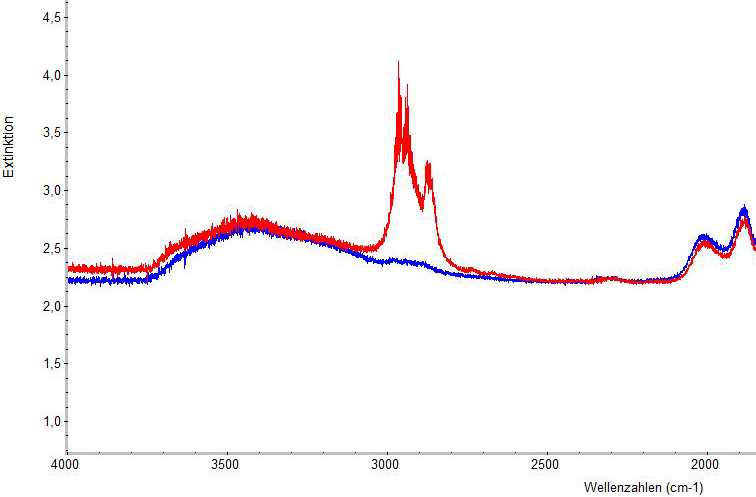

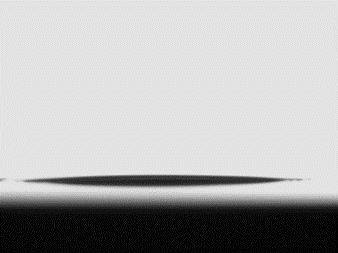

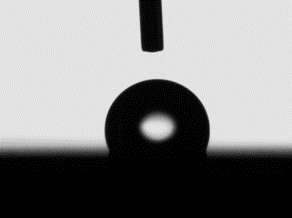

By using materials with different transport properties, mixed matrix membranes have enormous potential for applications in a wide variety of separation processes, with a versatile property profile resulting in particular from a large number of different polymers. By modifying the membrane surfaces, we are able to adjust hydrophilic or hydrophobic properties, for example. We realize hydrophilic mixed matrix membranes by means of chemical and physicochemical processes, for example by generating hydrophilic groups on the surface through bond breaks in the polymer matrix or by applying SiOx layers. Known technologies for this include pyrosil processes, etching processes, oxyfluorination, and peroxide, ozone, UV, and plasma treatments. For hydrophobic mixed matrix membranes, we use suitable adhesive groups such as perfluoroalkyl chains.

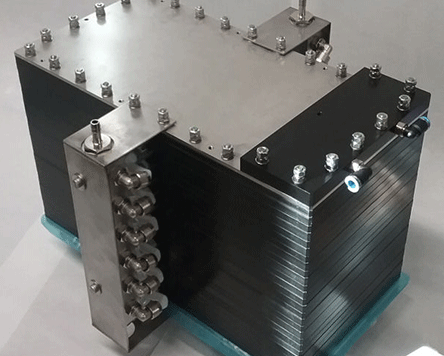

Accompanying the membrane development, we test mixed matrix membranes with regard to their permeability and selectivity. After successful testing, sample production can also be offered at the customer's request.

Services offered

- Development of composite membranes from different polymers and porous micro- and nanoscale fillers

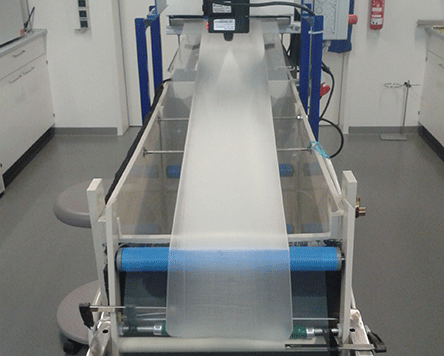

- Tape production from polymer solutions or via thermal and photochemical crosslinking of prepolymers

- Functionalization of micro- and nanoscale fillers (reactive groups, adaptation of wetting properties)

- Modification of membrane surfaces (adjustment of hydrophilic or hydrophobic properties)

- Membrane testing (permeability and selectivity)

- Sample production