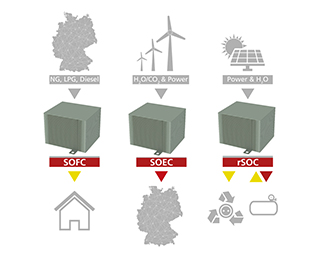

High-temperature fuel cells (SOFC) and high-temperature electrolysis cells (SOEC) have had a long history at Fraunhofer IKTS. The Ceramic Energy Converters workgroup did research on SOFCs (solid oxide fuel cells) as early as the 1990s and in doing so has gathered extensive know-how on the design and production of planar fuel cell stacks. The range of competences covers glass solder development, tape technology, as well as the design and processing of interconnectors, cell development and contacting on the gas and air sides, joining techniques, simulation and the initializing of SOFC stacks.

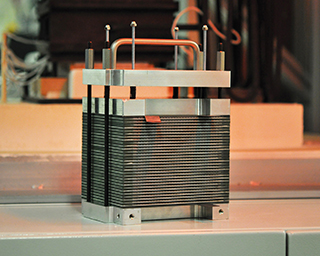

SOFC stack development

High-temperature fuel cell stacks are a core component in any SOFC system. Their performance and reliability, as well as the reproducible manufacturing at moderate cost, are prerequisites for fuel cell systems finding wider use on the market.

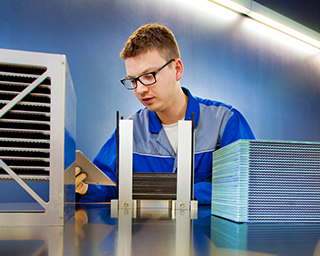

Researchers of Fraunhofer IKTS support users in the development of stack designs that are tailored to the client’s requirements. This includes the construction of prototypes as well as the testing of system performance using standardized and adapted characterization techniques. For instance, Fraunhofer IKTS develops with its partners fuel cell stacks for use in decentralized energy supply systems – from micro-CHP units to systems with more than 20 kW power. Furthermore, the research institution configures for its clients automatable manufacturing processes for the cost-efficient manufacturing of fuel cells.