High-performance energy storage systems are a key component of the energy transition. The central prerequisite is that energy storage systems are not only convincing from a technical-economic point of view, but also with regard to ecological sustainability. Fraunhofer IKTS is pursuing various approaches to close material cycles in battery cell production.

Materials recycling

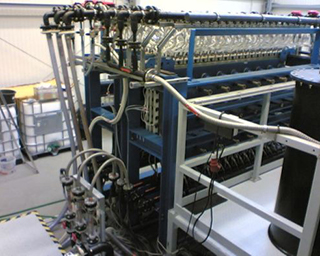

Raw material shortages, environmental pollution and inhumane working conditions in the extraction of raw materials will cause the demand for recycled battery raw materials to grow in the future. In order to meet this demand sufficiently, separation processes must be largely improved and made more flexible with regard to increasing recycling rates with higher-value material flows. To this end, Fraunhofer IKTS is developing recycling processes that can increase both the yield and the purity of recovered battery materials such as lithium, nickel or cobalt. This includes hydrometallurgical and electrochemical treatment processes on the one hand and the recovery of secondary raw materials from digestion media and process waters on the other. We use appropriate monitoring systems and database solutions to design recycling processes more in line with demand and to automate materials recycling.

Recycling of battery components

The recovered battery raw materials can be used for the production of new starting materials for battery manufacturing. With regard to the material and substance quality required for this, existing recycling processes are being specifically further developed for resynthesis processes and ecologically and economically evaluated. In addition, the influence of the use of secondary raw materials on cell performance is being investigated. Another approach to increasing recycling lies in cell design. Up to now, battery systems have not been optimized for recycling in terms of design and materials, so that batteries are usually mechanically dismantled at the end of their life cycle and the individual cells are sent for thermal recycling. In this context, Fraunhofer IKTS is developing design guidelines that enable recycling-friendly construction and thus improved recycling.