For system reliability in electronics, microsystems, and technical installations, the “Reliability of Microsystems” group at Fraunhofer IKTS offers numerical simulations for layout design, materials characterization for individual and composite materials in packaging, reliability assessments, in-situ test methods for measurement of stresses, and non-destructive test methods. Design of system reliability is focused on analysis of applied loads and measurement/calculation of stresses and subsequent effects on the system design (assembly layout).

Unique capabilities

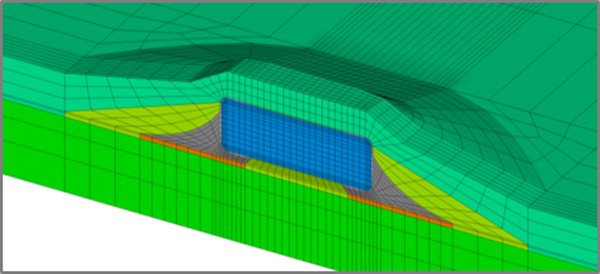

- Micromechanical characterization of solder materials and supply of material models for FEM simulations

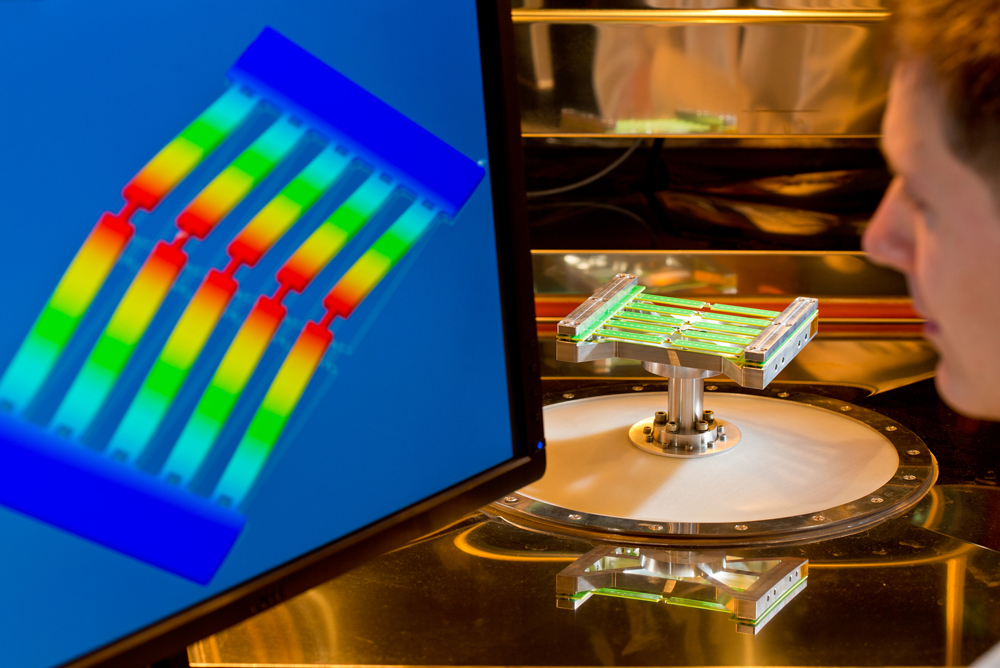

- High-resolution 3D X-ray computed laminography (HRCL, X-CT)

- In-situ measurement of forces and deformations in thermal cycling (TMF) tests

Services offered

- Creep and fatigue measurements on solder materials (-55 °C to 200 °C)

- Thermomechanical characterization of polymers, potting, adhesives, PCBs, and pastes by DMA and TMA measurements (-50 °C to 400 °C)

- Fatigue measurements on packaging materials, derivation of fatigue models for prediction of service life

- In-situ resistance measurements in TMF tests (168 channels, -50 °C to 175 °C)

- Vibration tests on components and assemblies (10 Hz to 4000 Hz, variable temperature)

- Microscale optical deformation measurements

- Structural mechanics FEM calculations (thermal, mechanical, and biomechanical)

- Development of design support tools (FEM)

- Physics of failure and damage analysis in electronic assemblies and microsystems

Technical infrastructure

- X-ray diagnostics

- X-ray chamber for X-ray CT, X-ray µCT and X-ray laminography (HRCL) of e.g., electronic assemblies

- X-ray diffractometer Seiffert PTS 3003

- Optical inspection

- Digital microscope Keyence VHX-5000

- Profilometer Keyence VR-5200

- ODU for FEM validation under thermal load

- Laser vibrometer for sound field measurement

- Thermographic camera

- Physical characterization

- Tension and compression machine Zwick/Roell Z250 incl. temperature change chamber

- Tension and compression machine H&P with peel test pull-off device

- Adhesion pull-off tester Proceq DY-206

- Micro tensile and shear tester

- Lap shear tester XYZ-Tech, Dage

- Density measurement

- Thermomechanical characterization

- Dynamic mechanical analysis TA DMA Q800 incl. liquid nitrogen cooling

- Thermomechanical analysis TA TMA Q400 EM

- Sample preparation and specimen removal

- Large test specimen stock for various material groups, sizes, and geometries

- Planetary centrifugal mixer – Thinky Mixer ARE-250

- Metallography grinding and polishing equipment

- UV chamber

- Salt spray system Köhler HK500

- Pressure chamber (ageing in maritime environment)

- Isothermal ageing

- Accelerated ageing

- Climatic chamber

- Vibration test rig LDS V455

- Thermal shock chamber (in-situ resistance and capacitance measurement)

- Temperature shock cabinet (in-situ resistance and capacitance measurement)