Miniaturized sensor system for packaging machines

Current research

Motivation

How can you determine the mechanical stresses that a product is subjected to during automated packaging? Producers and users of packaging machines have to answer this question in order to optimize packaging processes for high throughputs or to avoid defective goods through early detection of load changes.

Scientists at Fraunhofer IKTS have developed a miniaturized sensor system to address this problem. It is introduced into the customer’s packaging process with a wrapper that simulates the product. During the packaging run, the sensor system records the relevant data, which can be immediately forwarded to the machine manufacturer. This enables fast response times and rapid supply of replacement parts, which in turn leads to an increase in machine availability.

Furthermore, the sensor system can identify areas on the machine in which stresses on the products are high. Based on this information, the machine design can be optimized, for example, to achieve more gentle product handling with a simultaneous increase in throughput. The effects of the design changes are then immediately checked by the miniature sensor system.

System layout

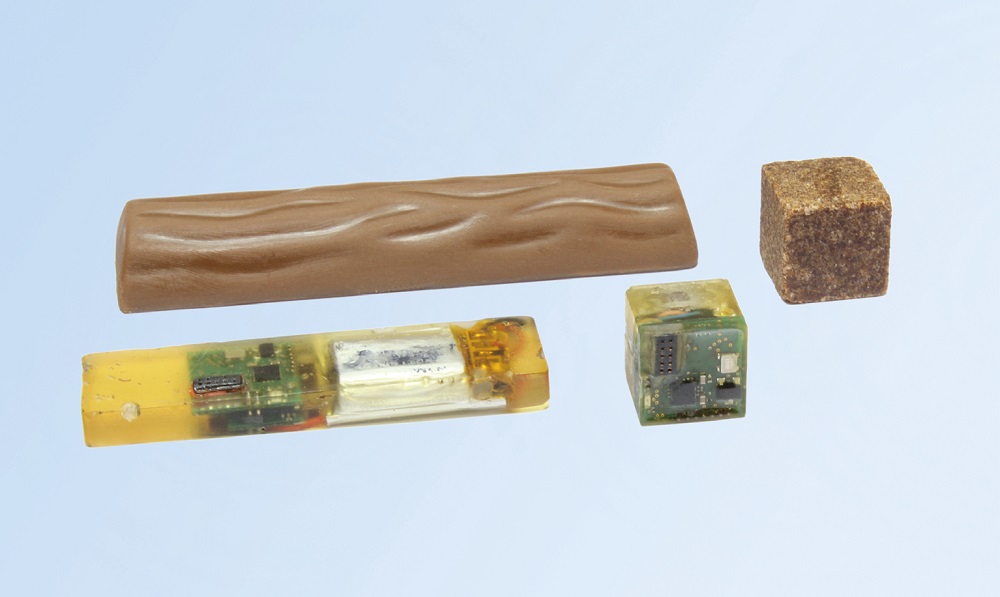

The miniaturized sensor system is designed modularly, is encapsulated, and can be realized with dimensions of as low as 12 x 12 x 12 mm or 12 x 24 x 6 mm. This makes it suitable for a wide range of applications. It is integrated into the product to be packaged and can easily be segregated from the regular products after packaging via electromagnetic locating. During the packaging run, accelerations of up to ±2000 m/s² are recorded in three axes at sampling frequencies of up to 10 kHz and angular velocities of up to 4000 °/s at frequencies of up to 1 kHz.

The sensor system has a data storage system for the saving of several measurement series. Configuration is accomplished via a PC interface prior to measurement. The measurement itself is started wirelessly by integrated Hall sensors using an external magnetic field. A rechargeable battery ensures a long sensor module service life.

With the developed sensor system as a starting point, individual customer preferences such, as wireless data communications or power supply, can be realized.

Further miniaturization of the system is planned for the future so that the production and value-adding process can also be monitored in industrial semi-finished products.