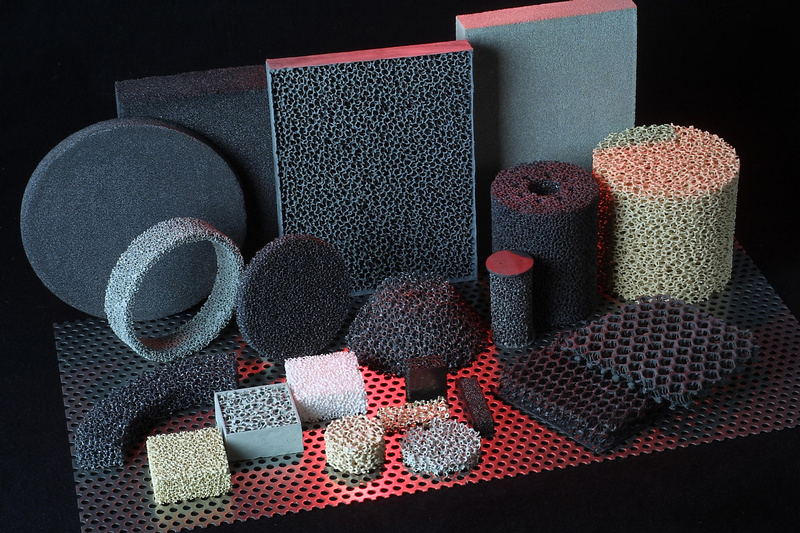

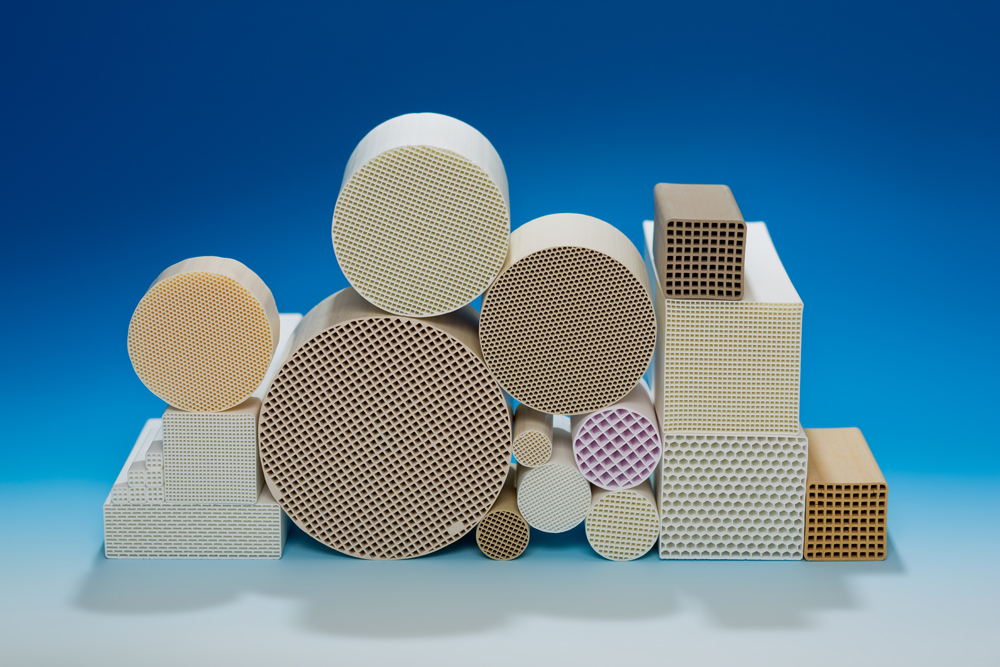

Porous ceramics can be manufactured in a high variability of pore sizes, pore size distribution and amounts of open and closed porosity. Applications of these porous ceramics exist in the field of separation techniques and filtration (i.e. dedusting, diesel particulate filtration, filtration of liquids), sound and heat insulation, in chemical and thermal process engineering (i.e. catalyst supports, porous burners), medical technology (e.g. bone substitution materials) and in lightweight constructions.

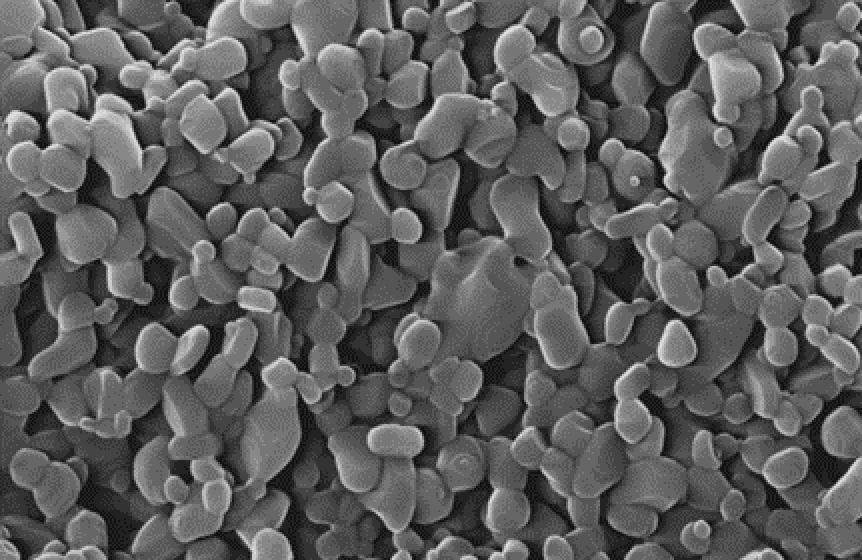

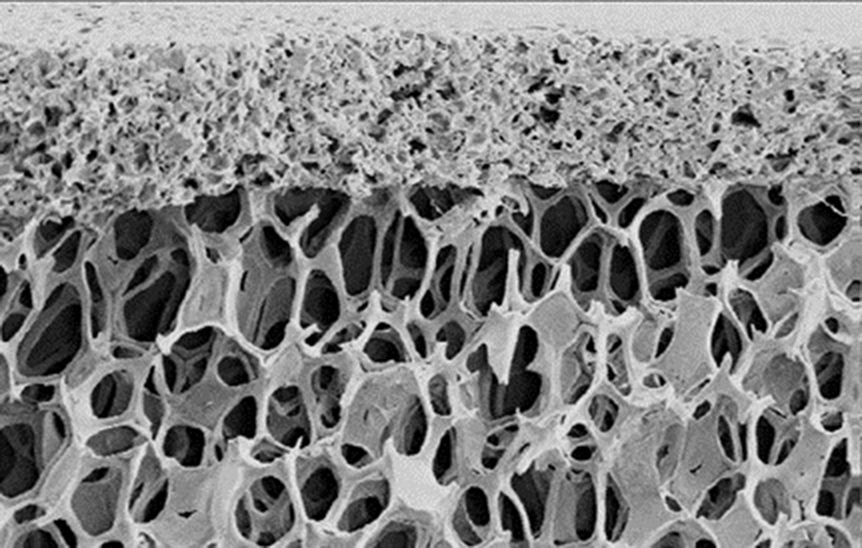

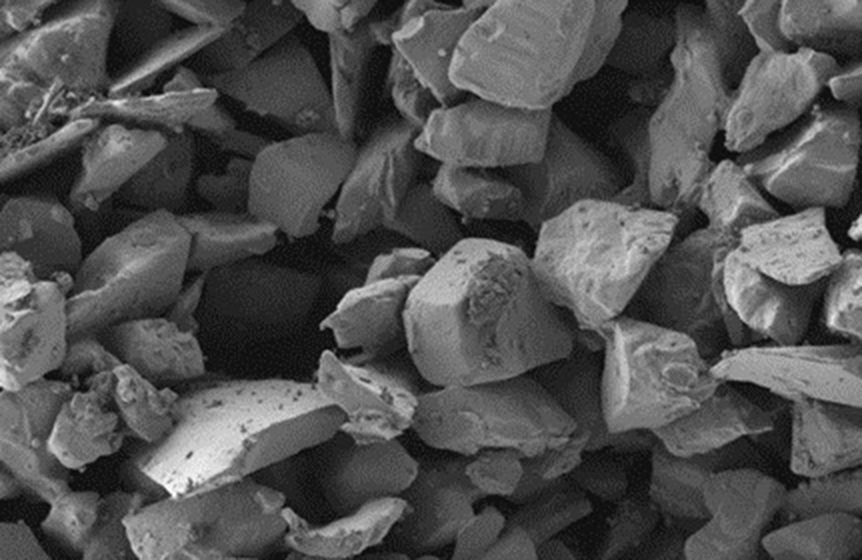

Fraunhofer IKTS is a strong research partner in the field of porous ceramics with numerous manufacturing technologies and components with pore sizes in a scale from nanometer to millimeter range. Cellular ceramics like foam ceramics are manufactured by the replica technique and can be characterized by their high pore volumes and available open porosity. With these properties, foam materials are predestined as excellent depth filters, which are needed for molten metal filtration. Additionally, they are suitable carriers for catalysts and storage materials. Similar pore sizes can be obtained with directly foamed ceramics, which can be realized with open and closed porosity. Via foaming procedure, the pore structure can be varied so that specific thermal and sound insulation properties can be achieved. These highly porous ceramics will be supplemented by grain ceramics with significantly smaller pore sizes and narrow pore size distributions. Fraunhofer IKTS develops these kind of porous ceramics for asymmetric filters or membrane filters whereby the pore structure can be varied gradually or continuously.