Did you know ...

... that we can not only hot-fire ceramic battery components, but also cold-sinter them?

We are testing these energy-efficient sintering technologies for the production of components for lithium and sodium solid-state batteries.

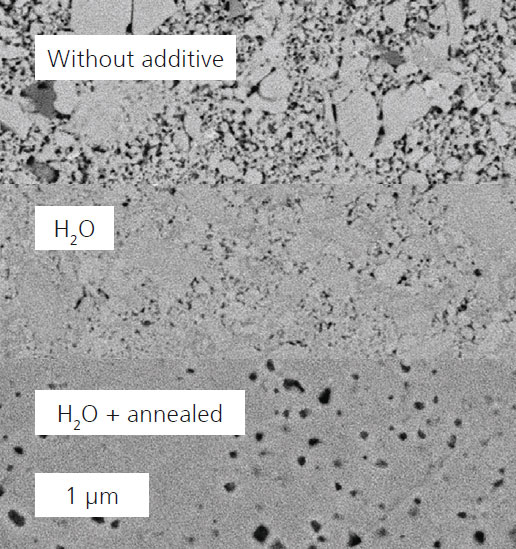

Cold sintering of materials for solid-state battery applications

In addition, we develop sulfide electrolytes, including testing of suitable processing and analysis methods. The focus is always on scaling up processes for industrial production.

Battery development at the Fraunhofer Project Center ZESS

In the field of sodium batteries, after more than ten years of development at Fraunhofer IKTS, the industrialization of the ceramic cerenergy® battery by Altech Batteries GmbH is now starting. Accompanying the establishment of the production in the Schwarze Pumpe Industrial Park, IKTS will accompany the conversion of the battery prototype into a product and the upscaling of the production to industrial scale.

Joint Venture Altech Batteries GmbH – 100 MWh battery factory in Schwarze Pumpe

For stationary energy storage, Fraunhofer IKTS is also working on medium-temperature batteries, combining sodium, sodium-beta-aluminate and transition metal oxides into a novel cell concept.

A novel cell concept for sodium-based medium-temperature batteries

Another focus of our battery research is on holistic, integrated solutions for closing the loop in battery production that are tailored to industry requirements. Here we are testing energy- and resource-efficient processes for the recovery of lithium and cobalt.