Technology

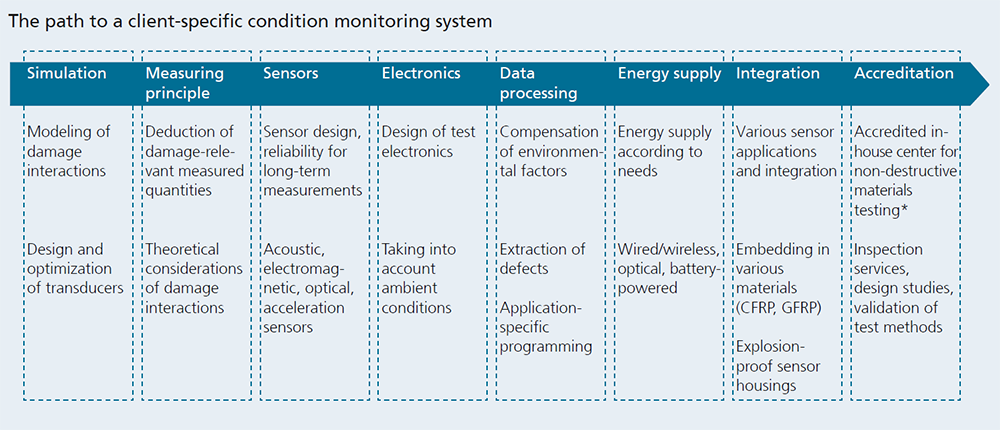

Every CM system is unique: Corrective, informative or predictive – only a customized maintenance strategy will lead to a longer service life and cost savings. CM systems by Fraunhofer IKTS focus on identifying, recording and assessing the decisive parameters. The intelligent systems may predict damage based on probabilities, increasing the availability of plants and components.

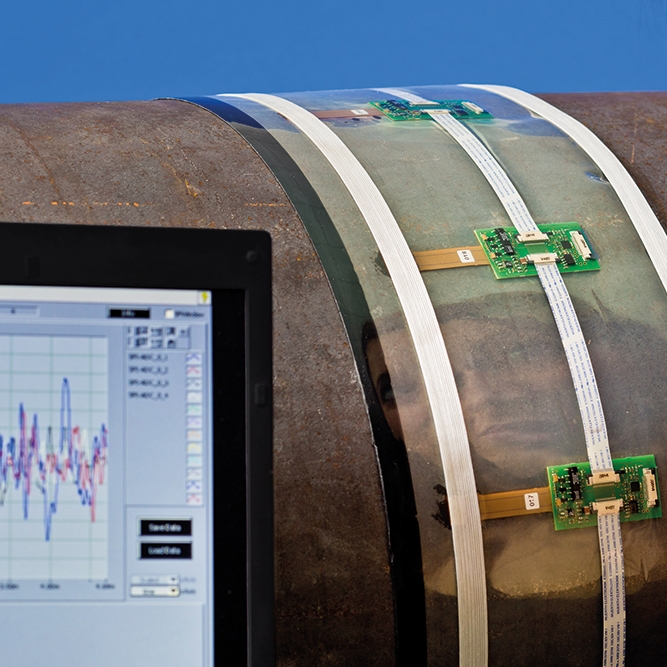

Fraunhofer IKTS develops, builds and integrates measuring systems for condition monitoring depending on their intended use, i.e. for processes, plants or components. Depending on operating conditions and client requirements, the systems can either be installed temporarily or remain on the structure for a longer period of time.

The decision on whether monitoring should be permanent depends on the length of measuring intervals and the required resolution capability of the results.

When several sensors are combined in a network, it becomes possible to correlate several measuring parameters, in addition to monitoring extensive structures.

In order to minimize interference with the monitored object and its environment, the condition monitoring systems can be combined with wireless technology developed at IKTS, as well as autonomous energy supply units.

The aim of condition-based monitoring is to improve resource planning and design MRO processes in accordance with actual needs.

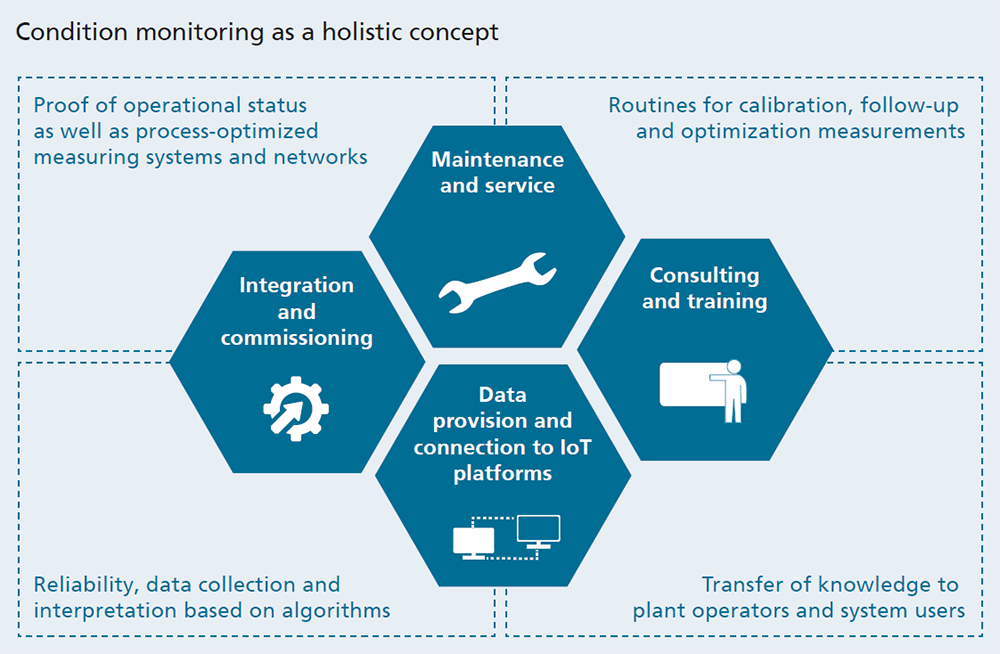

Therefore the requirements for a truly innovative monitoring system go beyond the scope of a traditional implementation, i.e. the integration of individual sensors or extensive sensor networks including professional commissioning.

Fraunhofer IKTS actively pursues the approach of a complete condition monitoring management – from conceptualization to final integration. Our close partnerships with the industry and with other research institutions allow us to connect monitoring systems to available IoT platforms, based on universal interfaces and using the latest automation architectures. This includes not only the vertical integration of the recorded data, but also horizontal data provision for subsequent processes.

The data are consolidated to obtain conclusive information before being transferred via safe networks. The web-based presentation of data can take place in a user-friendly way, on mobile terminal devices.

This holistic approach is completed by client-specific consulting services and training options for employees.