Quality assurance laboratory

Testing can be performed alongside development in nearly all areas of quality assurance according to national and international standards or customer-specific programs. Detailed environmental, material, and safety tests are performed in a fully equipped testing laboratory by well-versed staff with extensive experience in test planning, execution, and evaluation. Other activities include jig/fixture construction and regular calibration of the measuring and test equipment.

Fraunhofer IKTS can perform a wide range of standard and non-standard, customer-specific tests in a laboratory that has been audited and accredited by VDE, TÜV Nord, and DAkkS (Deutsche Akkreditierungsstelle GmbH).

The technical infrastructure at Fraunhofer IKTS encompasses a laboratory equipped for conducting electrical, environmental, material, and safety tests, a laboratory for mechanical testing, and a calibration laboratory. Safety and reliability tests are performed on products and materials using standardized test systems and processes. The related test marks (e.g., TÜV “Type Approved” mark) can be issued based on the results of these tests. The testing laboratory has been certified as a CBTL (certified testing laboratory) by the IEC in cooperation with the national certification body VDE Prüf- und Zertifizierungsinstitut GmbH.

The Quality Assurance Laboratory has received flexible-scope accreditation from the DAkkS for certain electrical test procedures. The latest quality standards (ISO 9001, ISO 10012, etc.) prescribe regular and preventive monitoring and calibration of the test equipment used. The calibration laboratory offers DIN EN IEC 17025-compliant factory calibration by competent staff. To supplement DAkkS accreditation of the testing laboratory, accreditation of the calibration laboratory is being sought.

Services offered

Accredited electrical testing of materials

- Volume resistivity in accordance with DIN IEC 60093

- Surface resistivity in accordance with DIN IEC 60093

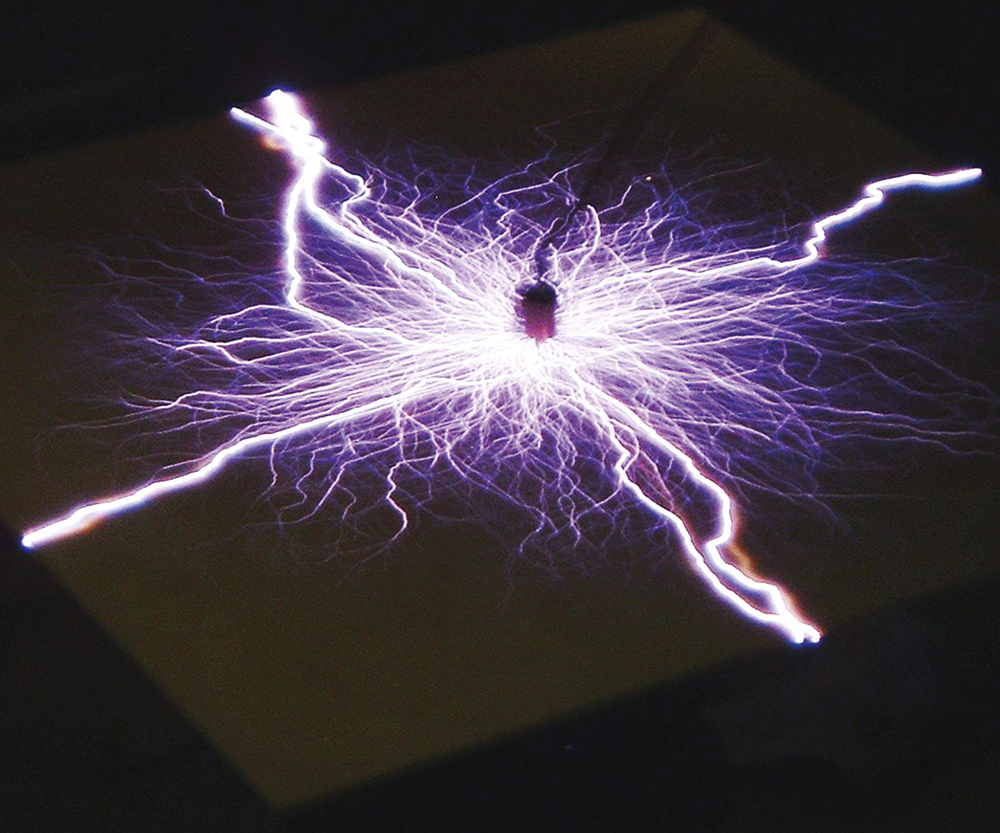

- Dielectric strength up to 100 kV AC/130 kV DC in accordance with DIN EN 60243-1

- IEC 250 dielectric properties (permittivity)

Non-accredited testing of materials

- Resistance measurement with temperature loading in accordance with DIN IEC 60345

- Arc resistance testing

- Low-voltage high-current testing in accordance with DIN VDE 0303-5

- High-voltage low-current testing in accordance with DIN EN 61621

- Determination of tracking and erosion resistance in accordance with DIN EN 60587 and DIN EN 61302

- Testing in accordance with DIN EN 60112 PTI/CTI

- Assessment of thermal hazards

- Ball pressure testing in accordance with DIN EN 60695-10-2

- Glow wire testing in accordance with DIN EN 60695-2-10

- Burner testing in accordance with DIN EN 60695-11-4

Safety and environmental testing

- Climatic testing

- Dual-chamber shock testing (-80/220 °C)

- Single-chamber shock testing (-30/150 °C with vibration load of up to 50 g)

- Temperature- and humidity-controlled aging (-70 °C to 190 °C and 0 % to 98 % relative humidity, chamber sizes up to 1.5 m3)

- Stress testing (-70 °C to 180 °C at 15 K/min)

- Thermal aging (up to 1600 °C)

- Condensation testing (100 % relative humidity)

- Vibration testing (5 to 2000 Hz, max. 600 kg, max. 100 g acceleration)

- Impact testing (max. 200 g, half-sine, trapezoid, saw-tooth)

- Salt spray testing in accordance with DIN EN ISO 9227

Safety and life testing

- Testing of components and products according to the latest standards as a basis for CE marking, TÜV “Type Approved” marking, or VDE marking pursuant to:

- DIN EN 60335

- DIN EN 60730

- DIN VDE 0620

- DIN EN 60669

- DIN EN 60668

- DIN EN 61210

- DIN EN 61558

- DIN EN 60598

- DIN EN 131 others on request

- Component and product life testing

- Testing within the scope of development

- Reliability and serviceability testing

Calibration

- Electrical parameters

- Voltage (0 to 40 kV)

- Current (0 to 550 A)

- Frequency (0 to 2 GHz)

- Electrical components

- Resistors (0 to 100 TΩ)

- Capacitors (10 pF to 1 mF)

- Inductors (1 μH to1 H)

- Temperature calibration

- Thermocouples and gauges (-75 °C to 1150 °C)

- Scale calibration (1 g to 100 kg)

- Force (0 to 100 kN)

- Torque (0 to 400 Nm)

- Humidity (20 % to 95 % relative humidity)

- Pressure (1 to 700 bar, oil or nitrogen as medium)

- Length calibration

- Calipers, dial gauges, final dimensions

- Micrometer screw gauges, geometry measurement

- Other types of calibration on request