Microstructural and material analysis

Fraunhofer IKTS has numerous characterization methods and a comprehensive equipment basis at its disposal for developing diverse high-performance materials. Drawing on its exhaustive experience with various materials and composites, the institute offers customers and project partners a wide range of services. Established, standard, and new methods are continuously being optimized to expand the knowledge base.

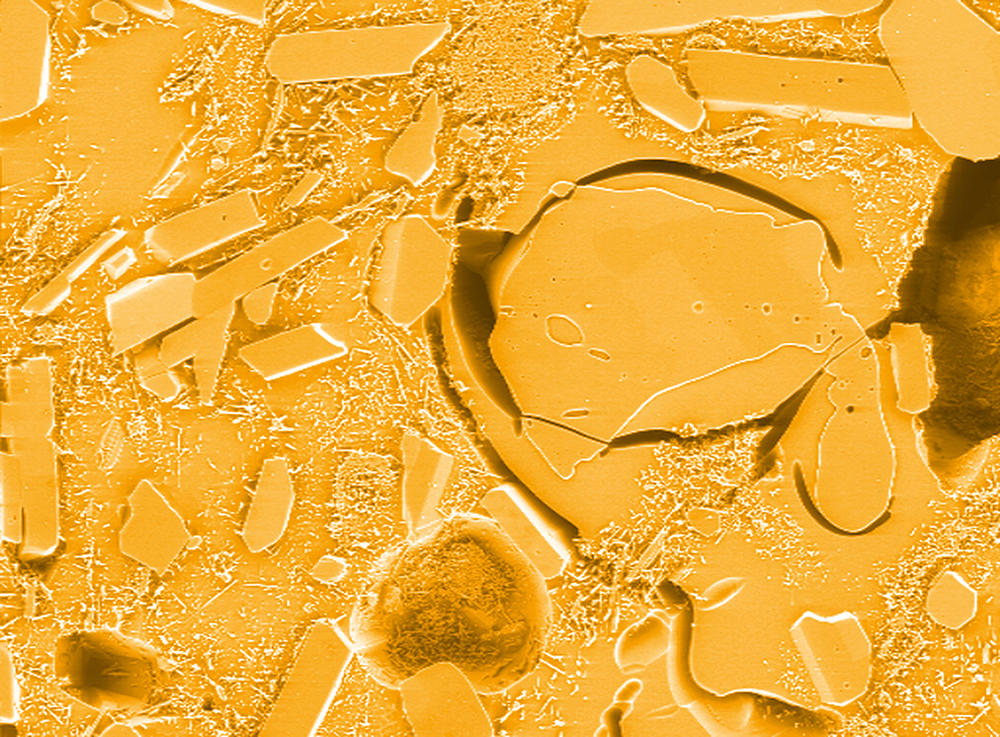

The topical and methodological focus of activities at Fraunhofer IKTS is on ceramics, hardmetals, and cermets. However, customers and project partners from the areas of metals and composites have also long been seeking out the institute’s expertise. Process-accompanying materials characterization, qualitative and quantitative microstructural analysis, and analysis of defects and weak points in components are the main investigations performed. Preparation and analysis methods are adapted to specific materials as well as continuously improved and optimized.

Work is done to the highest quality standards and supply of required information to customers is fast and efficient. Intermeshing of sample preparation and analysis equipment with different methods enables a variety of analyses to be performed all along the technology chain. Parameters are varied, e.g., in the FESEM, to yield the maximum amount of information from the sample.

Depending on the given application and requirements, an optimized characterization method can be developed for a specific material or product. Evaluation and interpretation offer customers effective additional information for the optimal use of the analysis results.

Fraunhofer IKTS’s range of offerings is continuously expanding in response to increasing demands on high-performance materials, innovative product fields, and new technical possibilities. Promising new methods, such as high-resolution three-dimensional imaging of small-volume samples via FIB tomography, have become established over the last few years. Three-dimensional element mapping can additionally deliver information on local compositions and inhomogeneities. Ion beam-based preparation methods enable delicate materials, such as granules, green bodies, or semi-sintered samples, to be prepared in a way allowing for high-resolution artifact-free imaging of the structures and microstructures. Local electrical conductivities can also be shown on micron and submicron scales.

Services offered

Materialographic sample preparation

- Mechanical sample preparation

- Chemical and physical etching processes for enhancing microstructural contrast

- Ion beam preparation methods, e.g., focused ion beam (FIB) preparation, ion beam polishing, ion beam slope cutting

- Preparation of electron-transparent samples for STEM and TEM imaging

- Target preparation

- Preparation methods for granules, green bodies, semisintered, and delicate samples

- Development of individual preparation methods

Microscopy

- Optical microscopy

- Confocal 3D laser scanning microscopy

- High-resolution field-emission scanning electron microscopy

- Transmission electron microscopy

- Atomic force microscopy (e.g., LFM, MFM, EFM, STM)

- Acoustic microscopy

High-resolution analysis methods

- Energy-dispersive X-ray analysis (EDX)

- Wavelength-dispersive X-ray analysis (WDX)

- EBSD phase and orientation analysis

- TEM (incl. EELS)

- High-resolution 3D imaging via FIB tomography and 3D EDX

- EDX coating thickness analysis

Chemical and phase analysis

- X-ray diffractometry (XRD; qualitative and quantitative analysis, measurement at room temperature and at high temperatures, thin-film analysis, reflectometry)

- X-ray fluorescence analysis (XFA) on raw materials, components, and liquids

- Micro-Raman and IR spectroscopy

- Determination of oxygen and carbon contents

Additional services offered

- Quantitative microstructural analysis (e.g., grain size analysis, porosity analysis, phase analysis, coating thickness analysis, determination of shape parameters)

- Interfacial analysis

- Analysis of corrosive reactions

- Failure analysis (estimation of mechanical, thermal, tribological, and corrosive loads, fractography)

- Determination of surface roughness